Intelligent manufacturing laboratory sintering device capable of preventing rotation errors

A technology for intelligent manufacturing and sintering devices, which is applied in the direction of furnace control devices, furnace monitoring devices, furnace types, etc., can solve problems such as reducing work efficiency, spending a lot of time, and rotation errors, so as to improve work efficiency and reduce manual labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

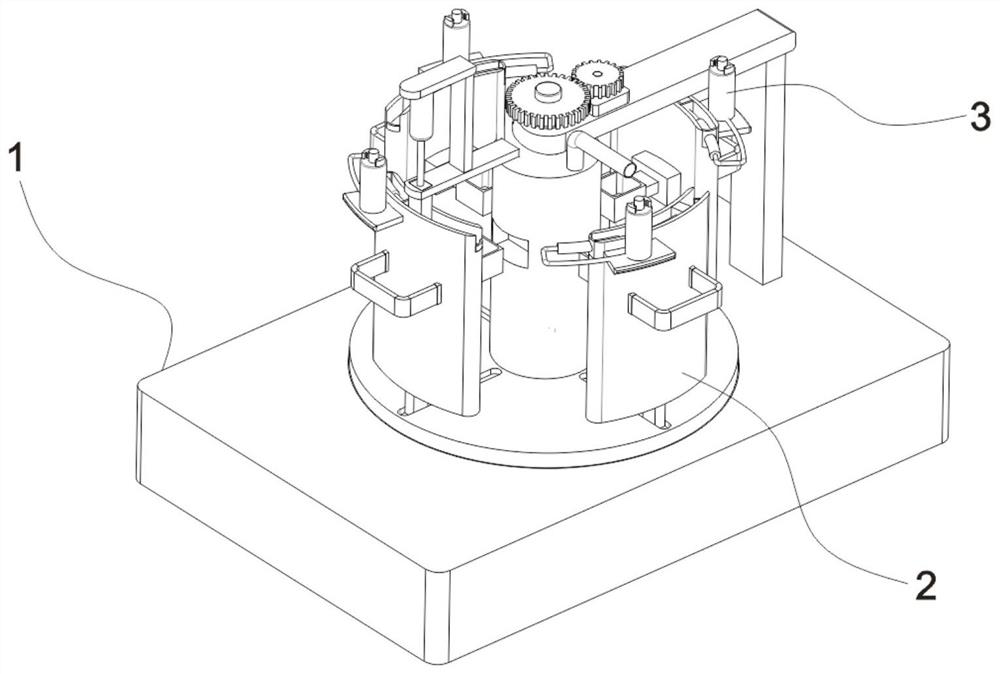

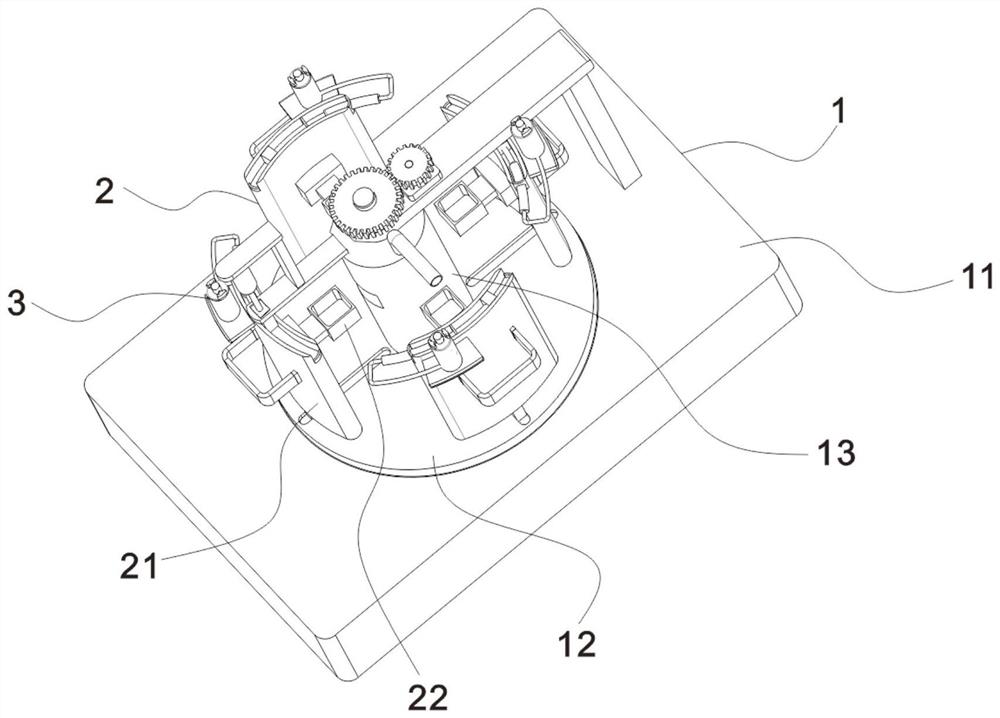

[0024] see Figure 1-5 , the present invention provides an intelligent manufacturing laboratory sintering device for anti-rotation error (electrical components in the present invention are all connected with external power supply by wires), including,

[0025] The receiving assembly 1 includes a base 11, and the top of the base 11 is movably embedded with a connecting plate 12, and the connecting plate 12 is driven to rotate by the driving device at the bottom. The driving device is a stepping motor, and the driving device is located inside the base 11 for Drive the connection plate 12 to rotate, and the center of the top of the connection plate 12 is rotated by a rotating shaft to be provided with a cylindrical heating box 13, and the outer wall of the heating box 13 has a socket that cooperates with the sintering spoon assembly 22;

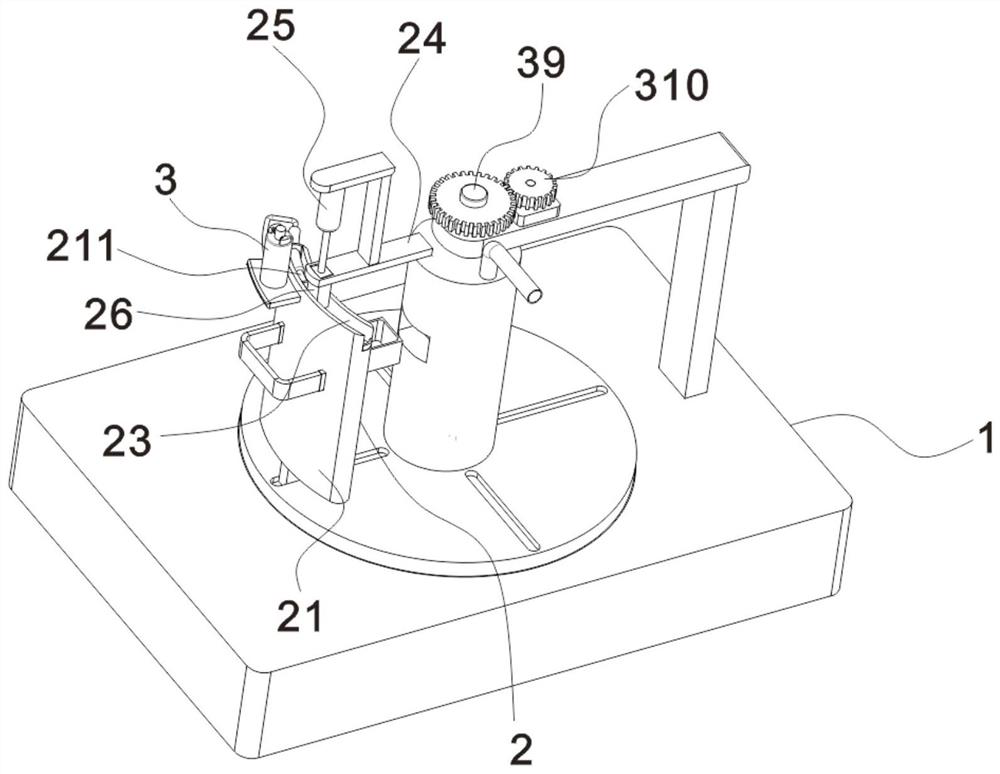

[0026] The detection type support assembly 2, the detection type support assembly 2 includes a plurality of groups of arc-shaped plates 21 slid...

Embodiment 2

[0031] see Figure 4, the feedback component 3 includes a detection cylinder 31 fixed on the top of the panel, the other end of the connecting air pipe 210 communicates with the bottom of the side outer wall of the detection cylinder 31, and the inner wall of the bottom of the detection cylinder 31 is fixed with a piston that matches the detection cylinder 31 through a connection spring 33 body 32, the top of the detection cylinder 31 is provided with a light sensor 38, the light sensor 38 is composed of a light receiver and a light emitter, and both the light receiver and the light emitter are electrically connected to the external controller, and the gas entering from the connecting air pipe 210 enters The detection cylinder 31 makes the piston body 32 move upwards in the detection cylinder 31. If the limit block 28 is in contact with the contact block 27, the light emitted by the light emitter is received by the light receiver through the through hole 37 on the bottom column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com