Automobile door handle transmission mechanism and working method thereof

A technology of a transmission mechanism and a door handle, which is applied in the field of auto parts, can solve the problems of thick handle thickness and large space occupation, and achieve the effects of prolonging life, saving space and not easy to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] like Image 6 , the support groove 42 includes a single support surface connected to the pushing guide surface 41 .

Embodiment 2

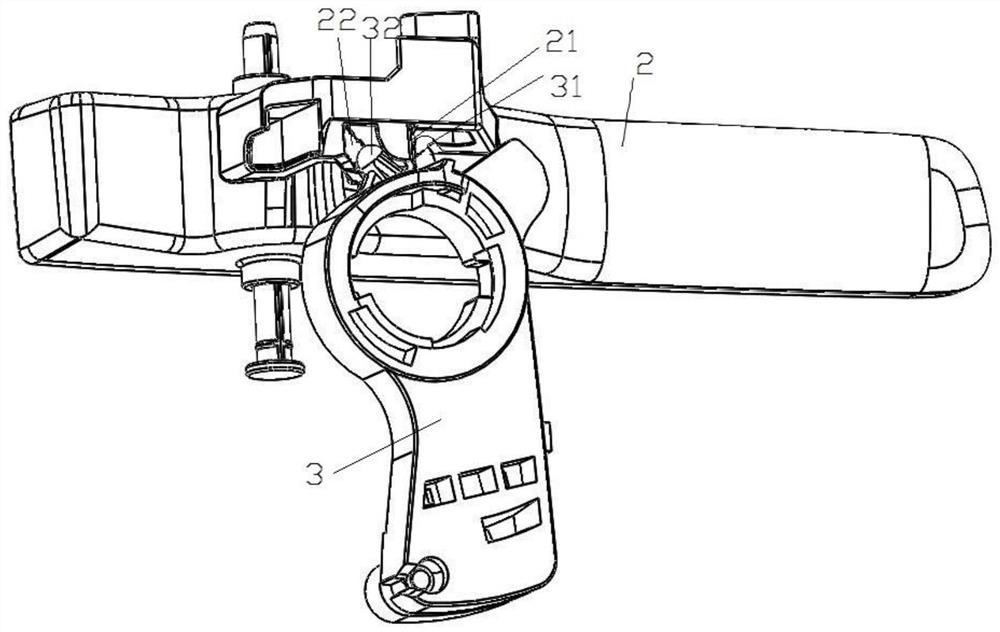

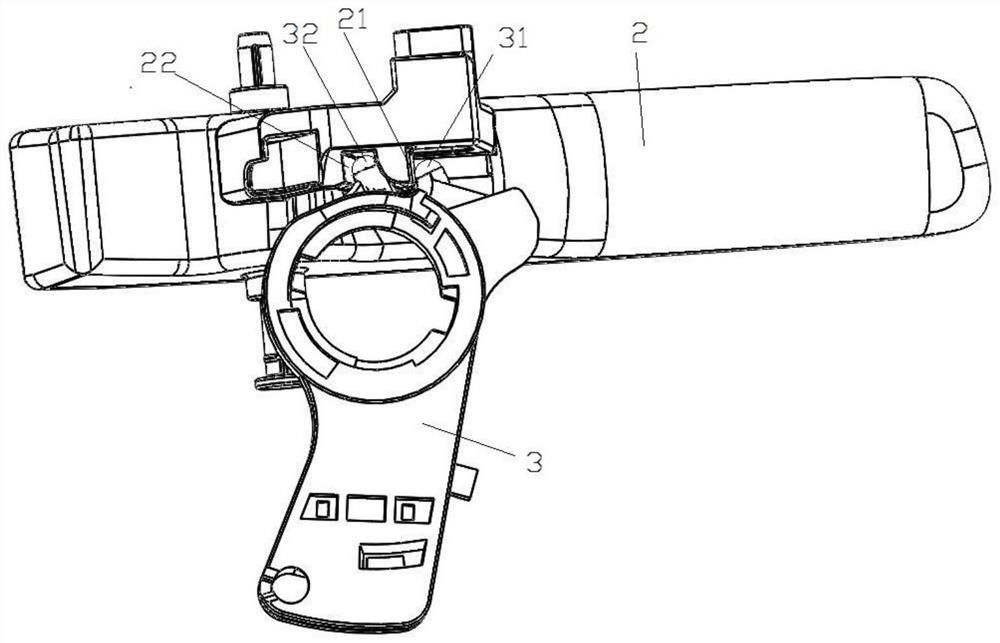

[0051] like Figure 7 and Figure 8 , the support groove 42 at least includes a support bottom surface 421 and a support side surface 422, the push guide surface 41 is connected to the support side surface 422, the support side surface 422 is arranged along the pushing direction of the slider 4, and one end surface 231 of the handle leg 23 is parallel to the support side surface 422 , and during the pushing process of the slider 4 , the extension surface of the end surface 231 changes from intersecting with the pushing guide surface 41 to being aligned with the supporting side surface 422 .

[0052] A working method of the above-mentioned car door handle transmission mechanism, comprising the following steps:

[0053] S1: The actuator 5 pushes the slider 4 out, and the slider 4 pushes the handle leg 23 to move to drive the handle 2 to rotate;

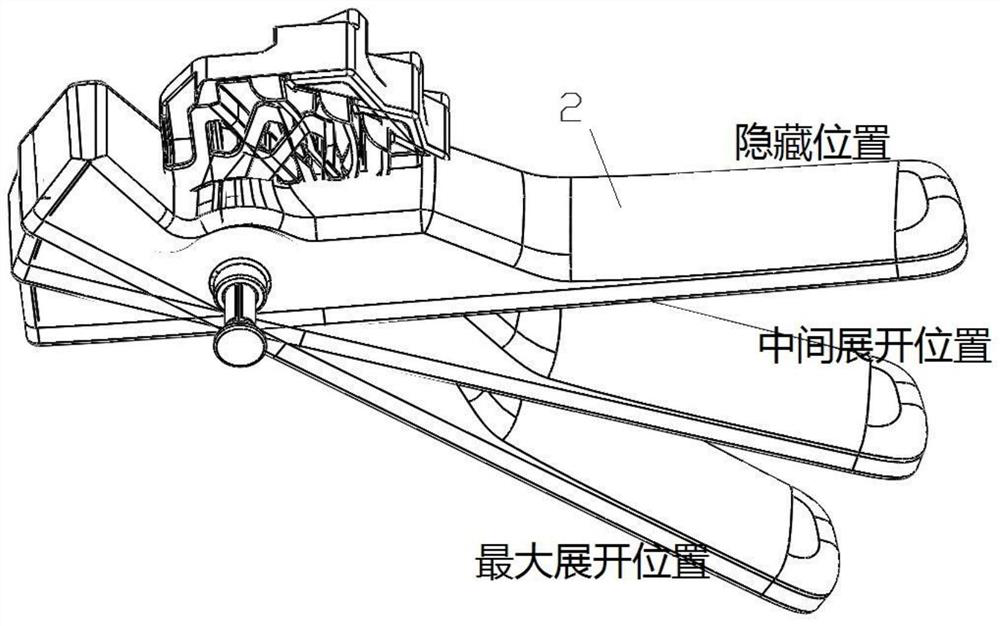

[0054] S2: The handle 2 is rotated from the hidden position to the middle unfolded position, and then the supporting groove 42 coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com