Novel pickling and oil removing device for guide pipe

A catheter and pickling technology, which is applied in the field of catheter pickling and degreasing equipment, can solve the problems of catheter floating, large contact area, and affecting normal operation, etc., achieve rapid installation and disassembly, reduce the use of aluminum wire, and improve installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

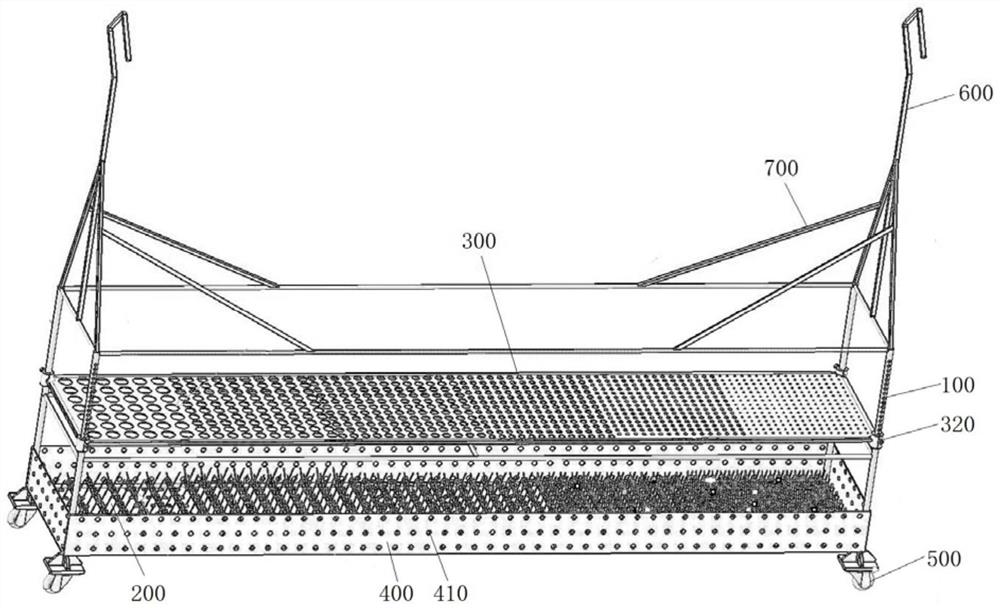

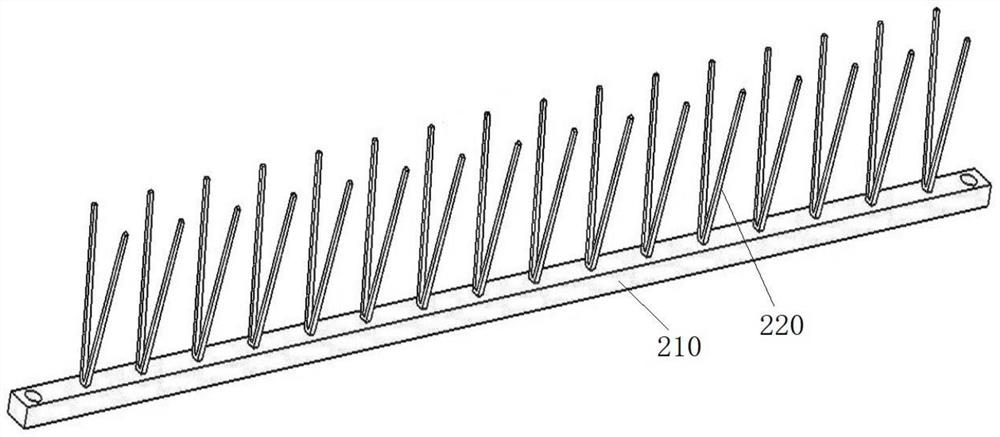

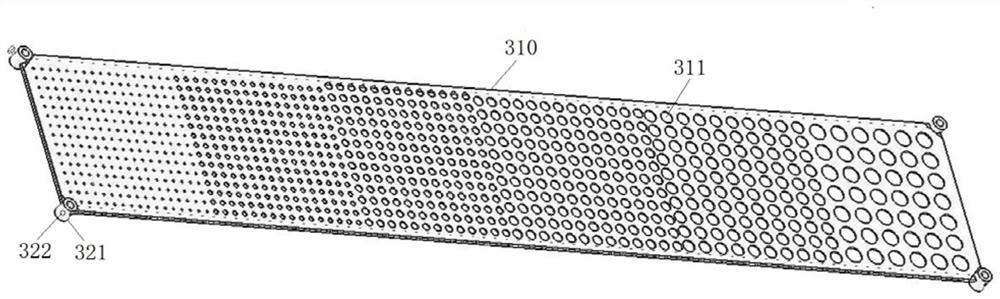

[0032] Such as Figure 1-3 As shown, this embodiment provides a new type of conduit pickling and degreasing device, including a frame 100, a first positioning mechanism 200, and a second positioning mechanism 300. The frame 100 is assembled from a plurality of columns and cross bars, generally surrounded by The quadrilateral structure can also be surrounded by a cylinder or a multi-faceted cube structure. The first positioning mechanism 200 is arranged in the frame 100. The first positioning mechanism 200 is used for positioning the bottom of the installation conduit. The second positioning mechanism 300 is arranged in the frame 100. The second positioning mechanism 300 is located above the first positioning mechanism 200. The second positioning mechanism 300 is used for positioning the top of the installation conduit. Multiple conduits can be installed between the second positioning mechanism 300 and the first positioning mechanism 200 with intervals between the conduits.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com