Cooling liquid for screw-type air compressor and preparation method of cooling liquid

A technology of air compressor and coolant, which is applied in the field of screw air compressor coolant and its preparation, and can solve the problems of high price and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

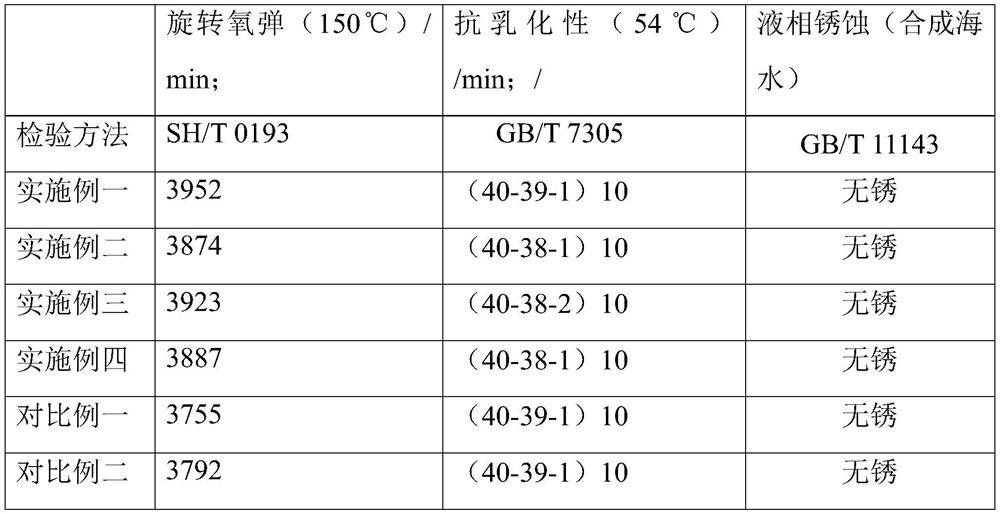

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the above-mentioned screw air compressor cooling liquid, comprising the following steps:

[0030] S1. Add secondary hydrogenated mineral oil and polymethacrylate to the reaction device, stir until transparent, add zinc diamyl dithiocarbamate, continue stirring until transparent, add composite additives and ashless antioxidant, The temperature is raised to 80°C-100°C, the temperature is maintained, and the reaction device is kept at a negative pressure of less than 0.09MPa; it is easy to remove trace moisture under negative pressure.

[0031] S2. Continuously detect the trace moisture of the substances in the reaction device. The trace moisture is controlled to cool down when it is not more than 50PPM, and the negative pressure is stopped after cooling for at least 10 minutes; excessive moisture can easily cause opacity in oil storage and affect the quality of oil products. Controlling trace moisture can Control...

Embodiment 1

[0038] This embodiment provides a cooling liquid for a screw air compressor, which includes the following components in parts by weight: 296.4 parts of secondary hydrogenated mineral oil, 1.35 parts of ashless antioxidant, 0.45 parts of polymethacrylate, and 0.45 parts of diamyl 0.45 part of zinc dithiocarbamate, 0.06 part of aliphatic aromatic hydrocarbon, 0.09 part of polyether polymer compound and 1.35 part of compound additive; ashless antioxidant is derived from ashless thiocarbamate and methyl benzene triazole composition of matter. The preparation method of the cooling liquid for the screw air compressor is as follows: closing the bottom valve of the reaction kettle, pouring 150KG of CNOOC's secondary hydrogenated oil 150SN and 146.4Kg of Formosa Plastics' secondary hydrogenated base oil 500SN under stirring, and circulating Add 450 g of polymethacrylate and stir for 5 minutes. After the liquid is transparent, add 450 g of zinc diamyl dithiocarbamate and continue stirri...

Embodiment 2

[0040]This embodiment provides a cooling liquid for a screw air compressor, which includes the following components in parts by weight: 330 parts of secondary hydrogenated mineral oil, 2 parts of ashless antioxidant, 0.6 parts of polymethacrylate, and dipentyl 0.6 part of zinc dithiocarbamate, 0.1 part of aliphatic aromatic hydrocarbon, 0.2 part of polyether polymer compound and 2 parts of compound additives; ashless antioxidant is derived from ashless thiocarbamate and tolutriazole composition of matter. The preparation method of the cooling liquid for the screw air compressor is as follows: closing the bottom valve of the reaction kettle, pouring 330KG of CNOOC's secondary hydrogenated oil 150SN under stirring, adding 600 g of polymethacrylate under circulation, and stirring for 10 minutes, the liquid is transparent Then add 600g of zinc diamyl dithiocarbamate and continue stirring for 30min. After the liquid is transparent, add 2Kg of Rheinland's screw air compressor coolan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com