Warehousing auxiliary device for track gasket machining

A technology of auxiliary devices and gaskets, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of high limitations, poor quality assurance of track gaskets, and low practicability, and achieve the effect of convenient promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

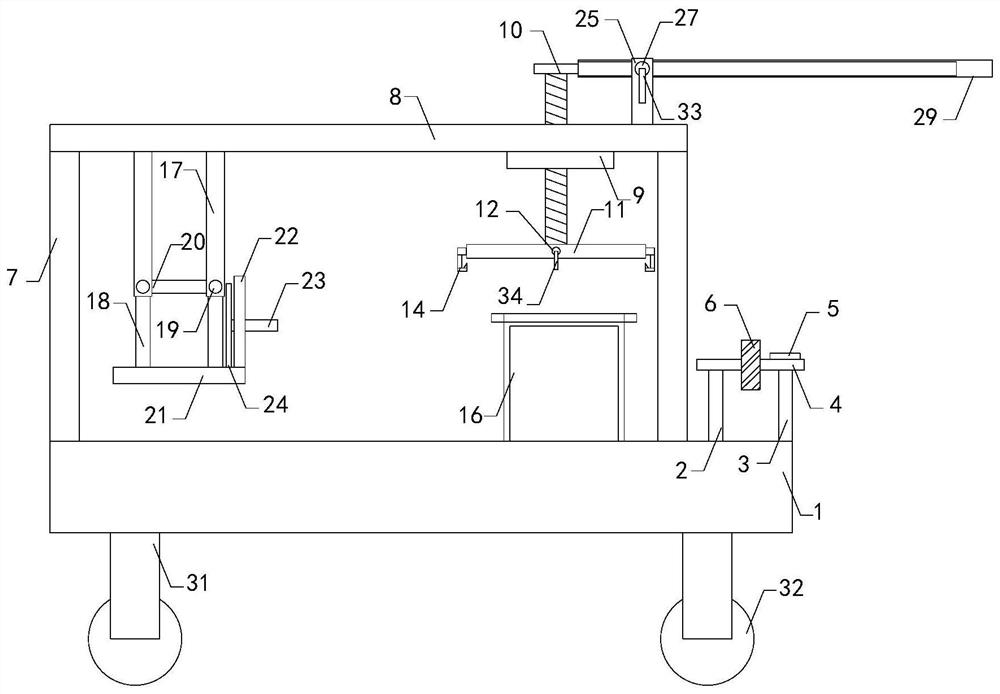

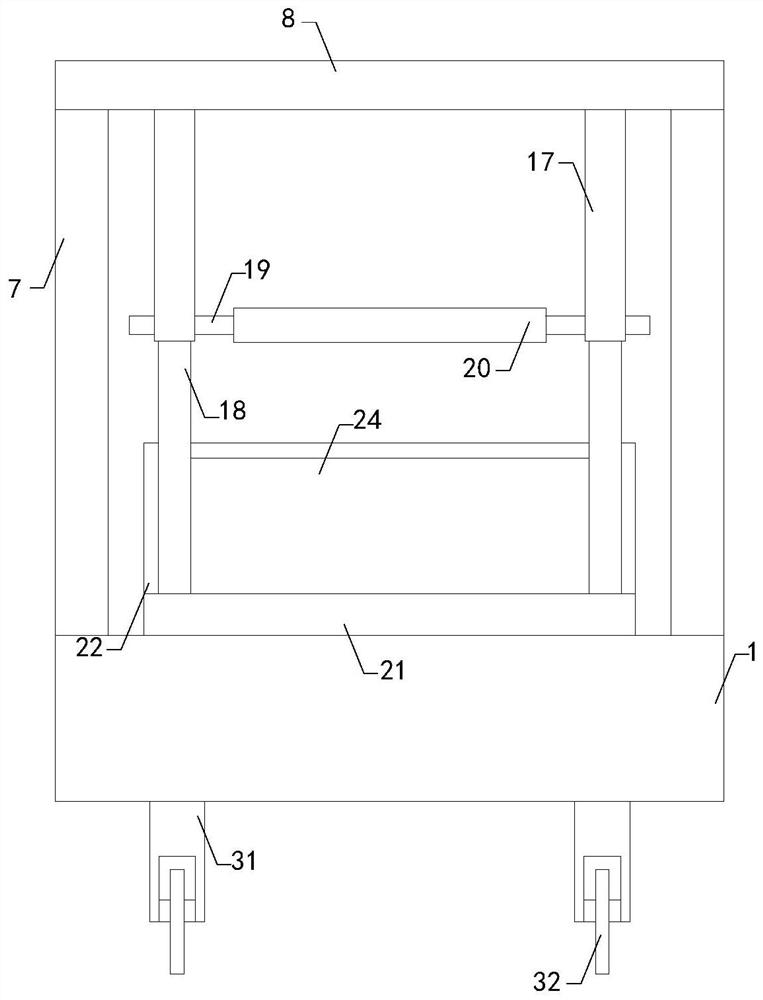

[0023] see Figure 1-4 , a warehousing auxiliary device for track gasket processing, comprising a bottom plate 1, a flaw detection device is provided on the top right side of the bottom plate 1, and the flaw detection device includes a first fixed rod 2 and a second fixed rod 3, the first fixed rod 2 The top and the top of the second fixed rod 3 are connected by a support plate 4, and the top of the support plate 4 is provided with a first slide rail, and the top of the support plate 4 is provided with a short plate 5, and the bottom of the short plate 5 is connected to the first slide rail. The slide rails are slidably fitted, and the circumferential outer wall of the support plate 4 is covered with an AC electromagnetic coil 6, and the top of the bottom plate 1 is provided with a rectangular fixed column 7, and the tops of each fixed column 7 are connected by a top plate 8, and the bottom of the top plate 8 Offer the chute that penetrates up and down, the bottom end of top p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com