Integrated operation mode and method for grape planting and photovoltaic power generation industry in soil-burying cold-proof area

A photovoltaic power generation and photovoltaic cell technology, applied in agriculture, application, cultivation, etc., can solve land waste and other problems, and achieve the effects of avoiding dust pollution, sufficient accumulation of active ingredients, and easy-to-learn grape pruning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (adopting cold-resistant varieties self-rooted seedling single row colonization Guyot shaping):

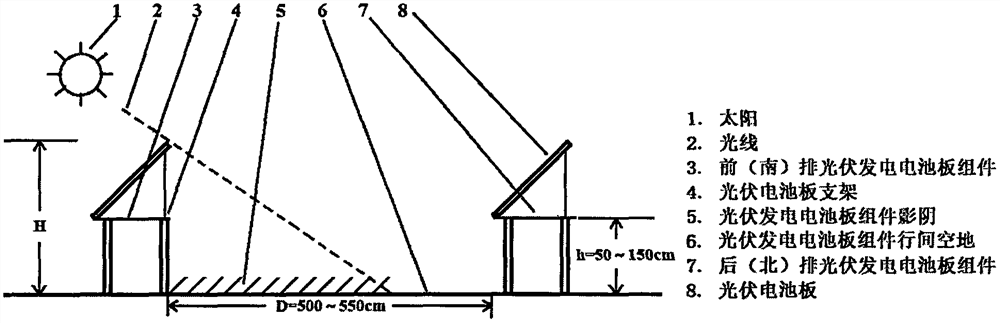

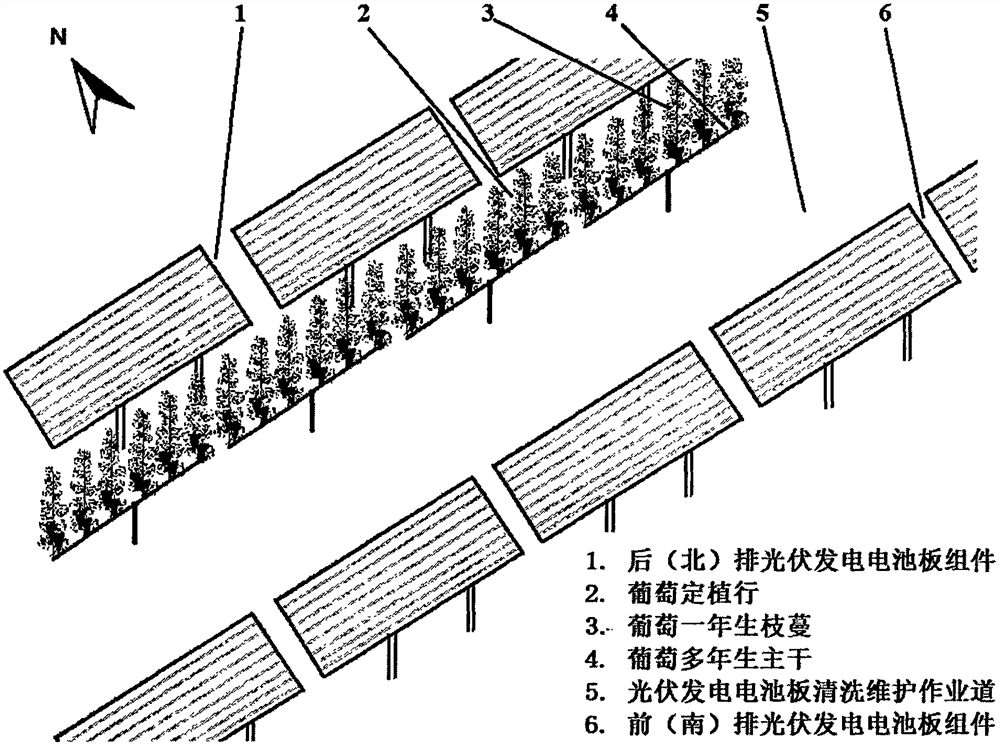

[0037] Between the two rows of photovoltaic cell module arrays of 500-550 cm, and 250-300 cm away from the back (north) row of photovoltaic cell modules, parallel to the photovoltaic cell module array, it is selected as a grape planting ditch. By every 666.7m 2 Apply 10-15m 3 Sprinkle the decomposed organic fertilizer evenly on the surface of the planting ditch, use an excavator to complete the ditch at one time, mix the topsoil and organic fertilizer and backfill to the bottom of the planting ditch with a width of 60-80 cm and a depth of 70-100 cm, and backfill the core soil to the surface of the planting ditch Form a 5-10cm deep planting ditch, and fill it with water to form a 10-20cm deep planting ditch. Then, cold-resistant grape varieties such as LaCrosse, La Crescent, Frontenac, Léon Millot, Zuoyouhong, Beibinghong, Beixi, Beimei, Beihong, etc. that can...

Embodiment 2

[0038] Embodiment 2 (adopting cold-resistant varieties self-rooted seedling double row colonization Guyot shaping):

[0039] Between the two rows of photovoltaic cell module arrays of 500-550 cm, at a distance of 200-250 cm from the back (north) row of photovoltaic cell modules, select two rows of grape planting ditch parallel to the photovoltaic cell module array with a row spacing of 100 cm. By every 666.7m 2 Apply 10-15m 3 Sprinkle the decomposed organic fertilizer evenly on the surface of the planting ditch, use an excavator to complete the ditch at one time, mix the topsoil and organic fertilizer and backfill to the bottom of the planting ditch with a width of 60-80 cm and a depth of 70-100 cm, and backfill the core soil to the surface of the planting ditch Form a 5-10cm deep planting ditch, and fill it with water to form a 10-20cm deep planting ditch. Then, cold-resistant grape varieties such as La Crosse, La Crescent, Frontenac, Léon Millot, Zuoyouhong, Beibinghong, B...

Embodiment 3

[0040] Embodiment 3 (adopting stress-resistant rootstock high connection single-row Guyot shaping and exempting from burying soil cultivation):

[0041] Between the two rows of photovoltaic cell module arrays of 500-550 cm, and 250-300 cm away from the back (north) row of photovoltaic cell modules, parallel to the photovoltaic cell module array, it is selected as a grape planting ditch.

[0042] By every 666.7m 2 Apply 10-15m 3 Sprinkle the decomposed organic fertilizer evenly on the surface of the planting ditch, use an excavator to complete the ditch at one time, mix the topsoil and organic fertilizer and backfill to the bottom of the planting ditch with a width of 60-80 cm and a depth of 70-100 cm, and backfill the core soil to the surface of the planting ditch Form a 5-10cm deep planting ditch, and fill it with water to form a 10-20cm deep planting ditch. Then, plant cold-resistant grape rootstock varieties that can survive the winter safely at a plant spacing of 80-150 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com