Rape cutting, airing and laying machine

A technology of laying and laying rapeseed, which is applied to harvesters, agricultural machinery and tools, agriculture, etc., can solve the problems of low chassis height of rapeseed windrowing machine, lower laying quality, increased picking operations, etc., and achieve good walking performance , Improve the effect of easy derailment, avoid skidding and car trapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

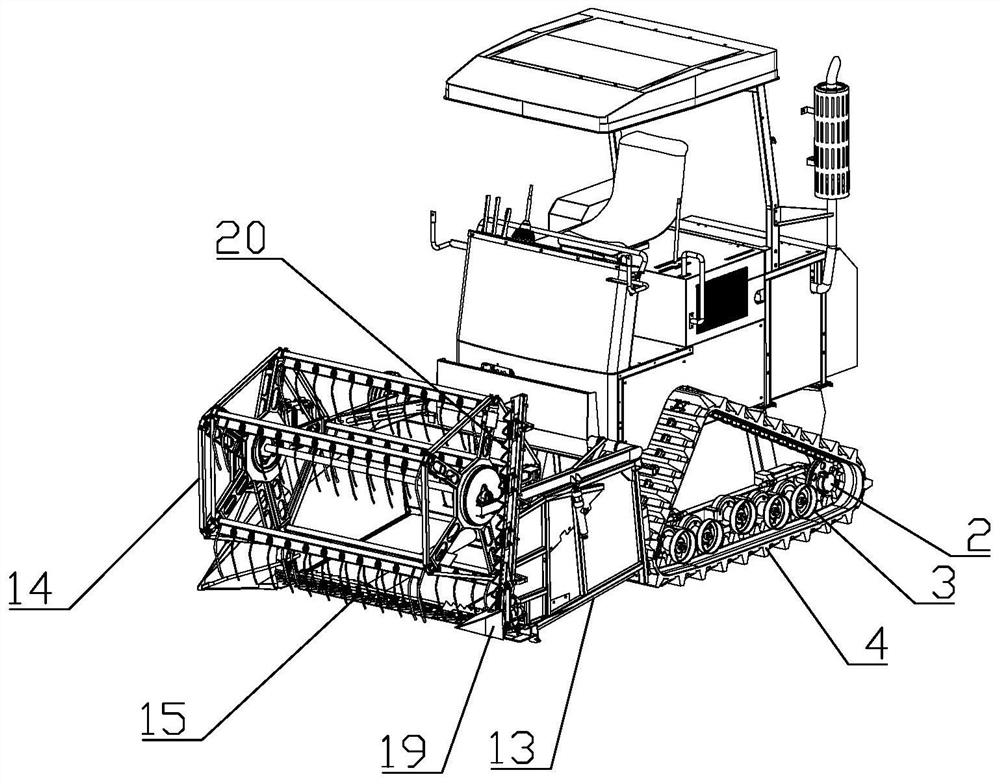

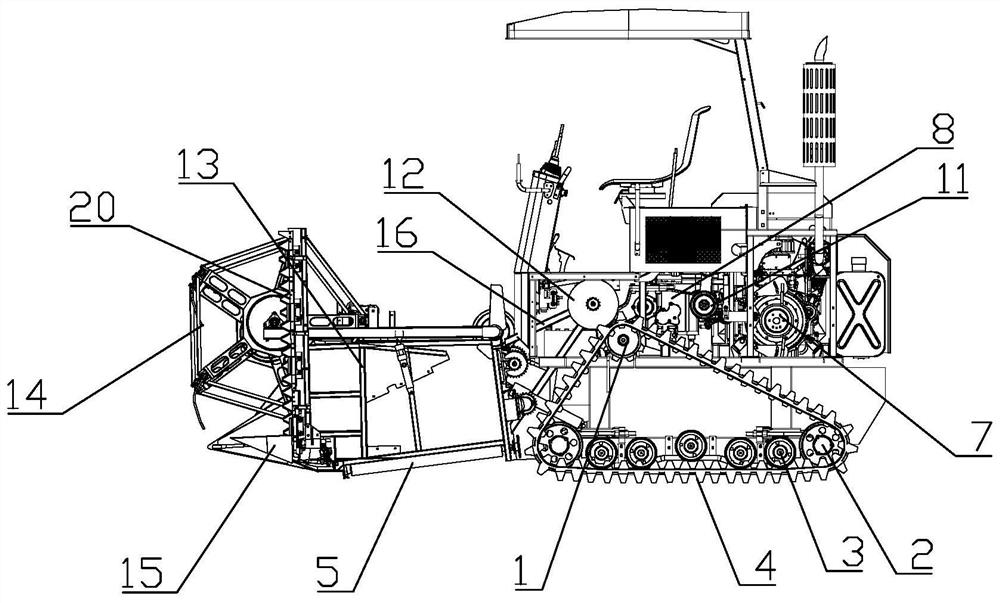

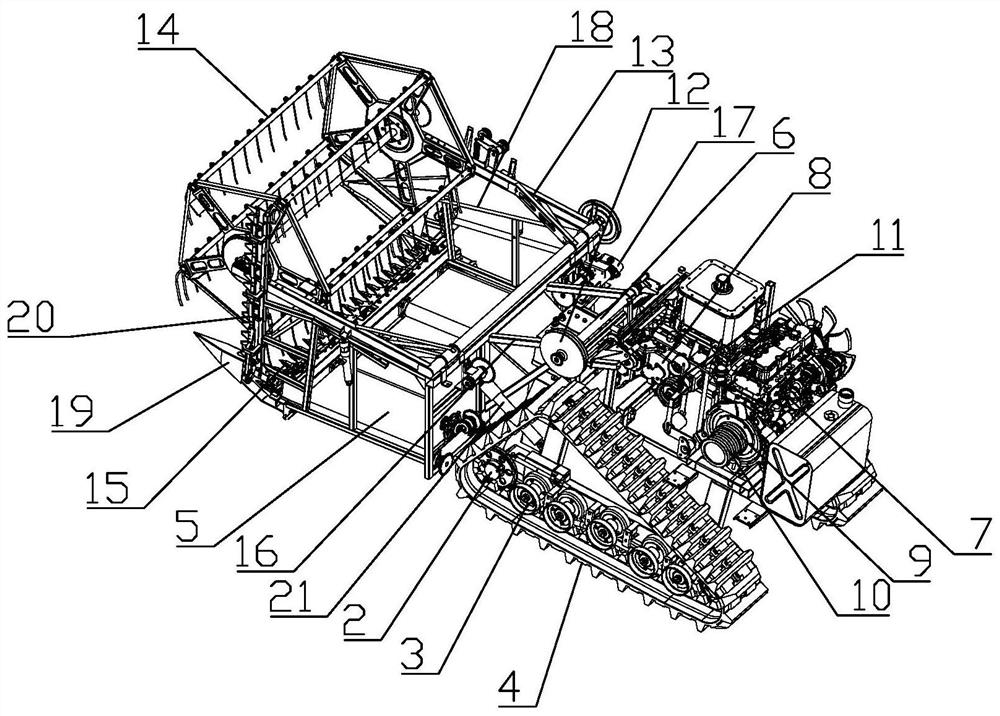

[0034]Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-10 :

[0035] Rapeseed laying machine, including main frame, chassis, power system, control system and header, said chassis includes triangular distribution of driving wheels 1 and a pair of tensioning pulleys 2, and several tensioning pulleys are arranged between them. Track roller 3, triangular crawler belt 4 is wound around driving wheel 1, tension wheel 2 and supporting roller 3 to form triangular crawler belt 4 type self-propelled system; Horizontal conveyor belts 5 are symmetrically distributed on the left and right sides and transported towards each other. There is a gap between the horizontal conveyor belts 5 to form a laying channel for rapeseed. The rear side of the header is provided with a horizontal header drive shaft 6. The two ends of the header driving shaft 6 are respectively connected with the conveying rollers of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com