Surface acoustic wave filter

A surface acoustic filter and resonator technology, applied in electrical components, impedance networks, etc., can solve problems such as intrusion, and achieve the effects of reducing intrusion depth, improving moisture and heat resistance, and slowing down the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

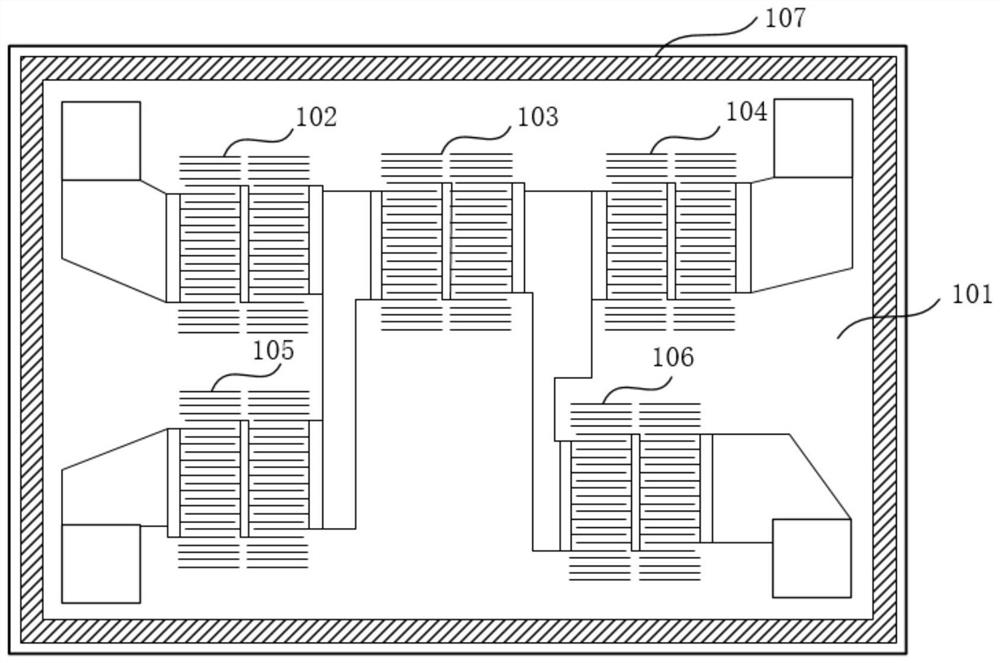

[0013] figure 2 The schematic plan view of the surface acoustic filter provided by Embodiment 1 of the present invention, this embodiment can be applied to the solution of preventing the intrusion of coating fluid by the surface acoustic filter including multiple resonators, the embodiment of the present invention provides a surface acoustic filter The surface acoustic filter includes a chip 101 and resonators 102-106 arranged on the chip, wherein, it also includes: a metal barrier bar 107, which is surrounded by the edge of the chip 101, and is used to block the coating film during the coating process. The fluid intrudes into the resonators 102-106.

[0014] Such as figure 2 As shown, this embodiment specifically uses a 5-step ladder-shaped surface acoustic filter as an example for description, but those skilled in the art know that it is not limited to a ladder-shaped surface acoustic filter.

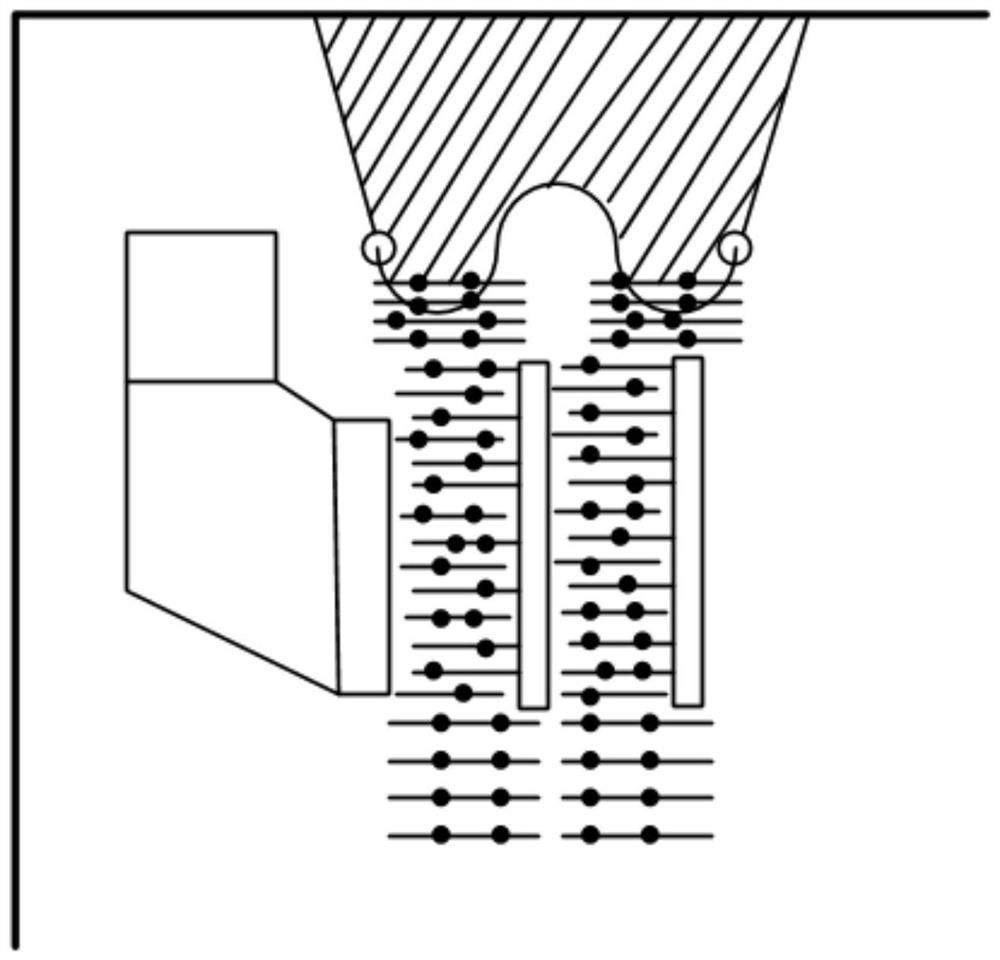

[0015] The surface acoustic filter is made of a metal film on a material subs...

Embodiment 2

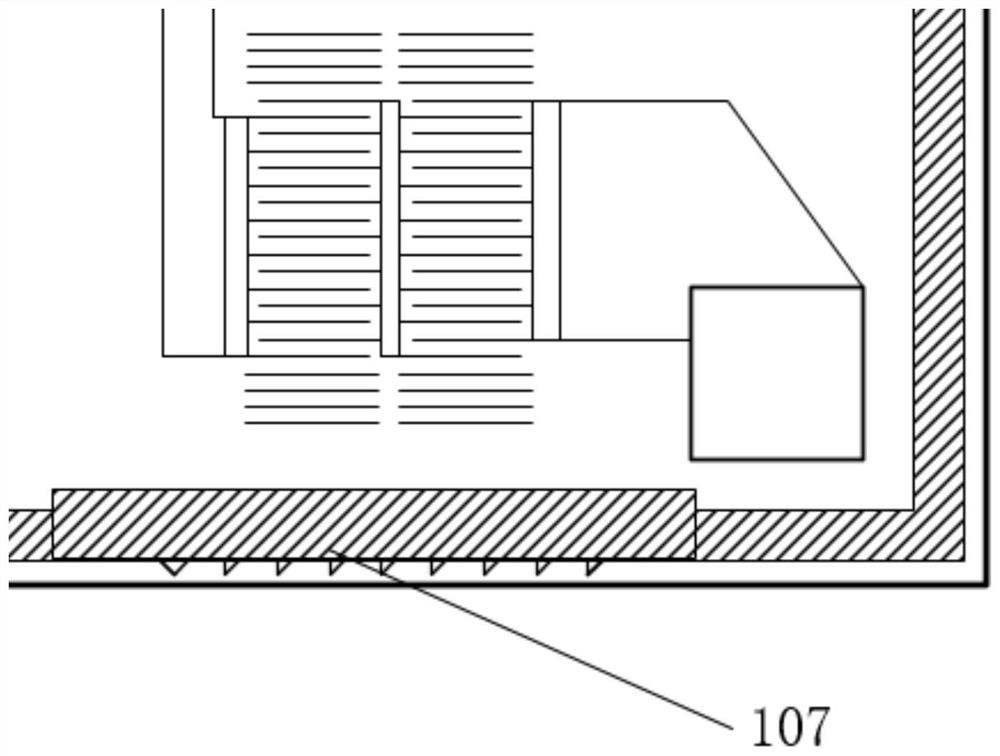

[0019] image 3 It is a schematic diagram of the surface acoustic filter chip provided by the second embodiment of the present invention provided with metal barrier bars. This embodiment is refined on the basis of the foregoing embodiments.

[0020] The metal barrier bars are formed by a sputtering process. The sputtering process is a process in which particles (ions or neutral atoms, molecules) of a certain energy bombard the surface of a solid, so that the atoms or molecules near the surface of the solid obtain sufficient energy and finally escape from the surface of the solid. Sputtering can only be carried out in a certain vacuum state. The sputtering coating technology uses ions to bombard the surface of the target, and the phenomenon that the atoms of the target are bombarded is called sputtering. The metal barrier bar is formed by sputtering process, which is equivalent to adding a metal fence to the internal circuit to prevent the coating fluid from intruding into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com