Cleaning machine drive control method and device, controller, storage medium and cleaning machine

A driving device and a cleaning machine technology are applied in the fields of storage media and cleaning machines, driving control methods for cleaning machines, controllers, and devices, which can solve problems such as damage to electrical components, melting of structural parts, temperature rise, etc., so as to prolong the service life. , the effect of not exceeding the temperature rise and increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

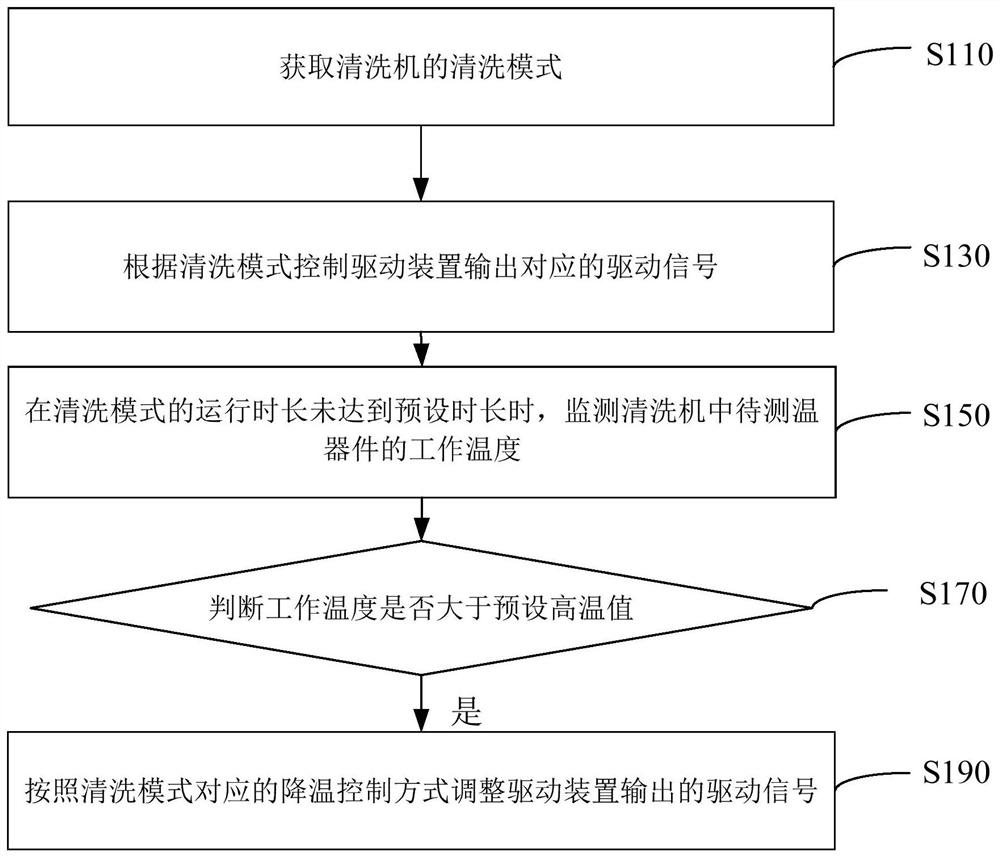

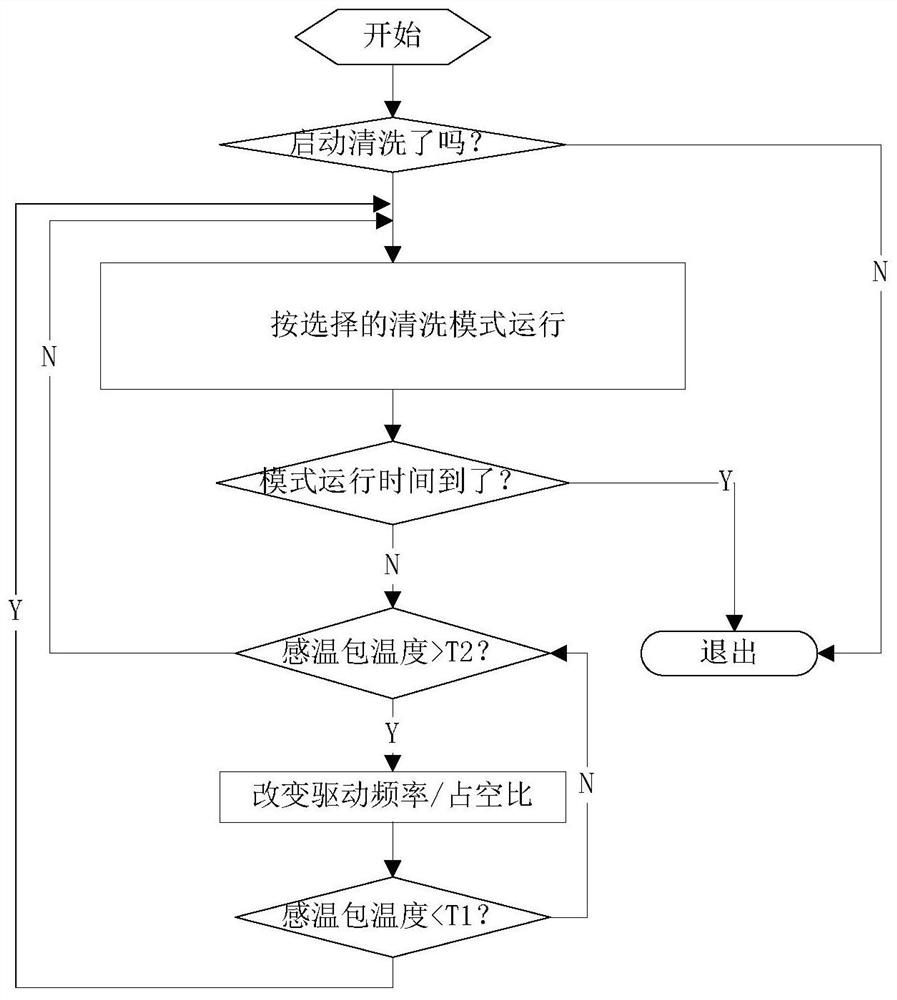

[0049] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, so as to solve technical problems and achieve technical effects by applying technical means to the present invention. The process is well understood and implemented accordingly.

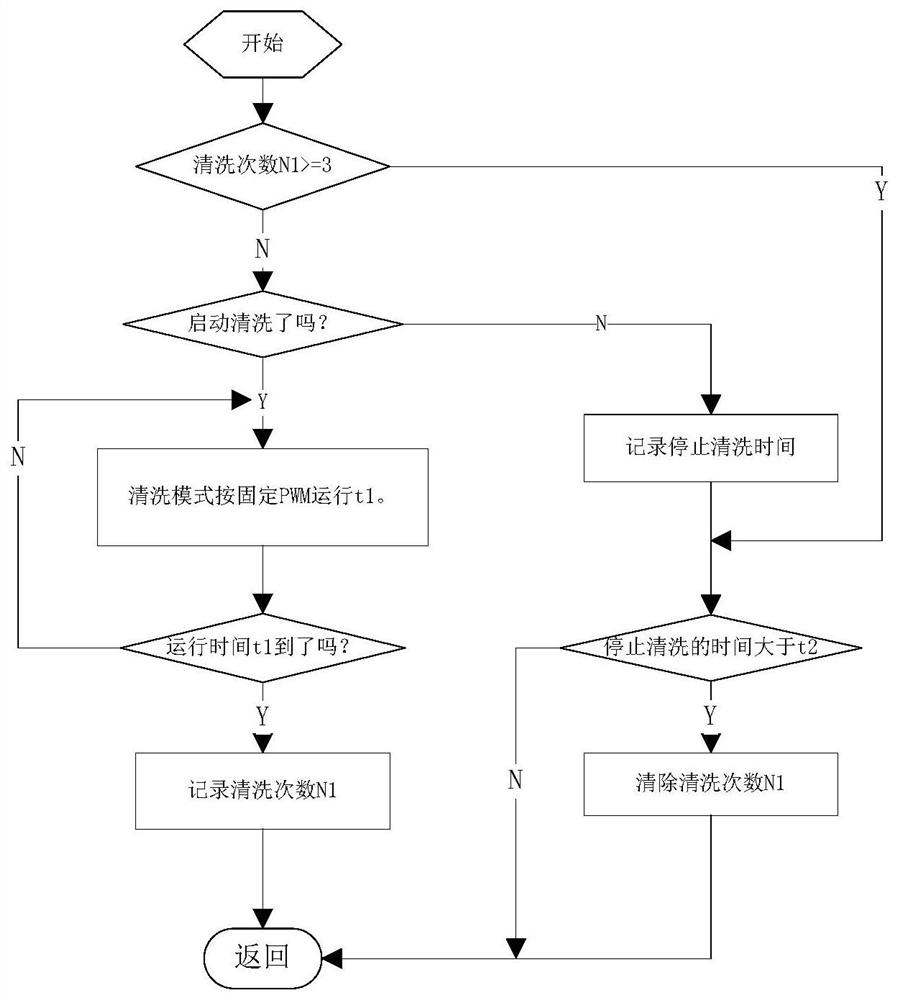

[0050] In the prior art, the conventional cleaning control logic of the washing machine is as follows: figure 1 As shown, in the cleaning process, run t1 according to the fixed PWM signal, and record the number of cleanings for each operation; when the number of cleanings is greater than the set number, stop cleaning for a period of time. The problems with this solution are as follows:

[0051] (1) The temperature rise of key components is not considered, which may easily lead to damage to structural parts or electrical components.

[0052] (2) Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com