Oil cooler with reinforcing ribs

An oil cooler and reinforcing rib technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of insufficient welding strength, difficult process, unfavorable requirements for automobile energy saving, etc. Processing time, reducing the overall weight, and ensuring the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

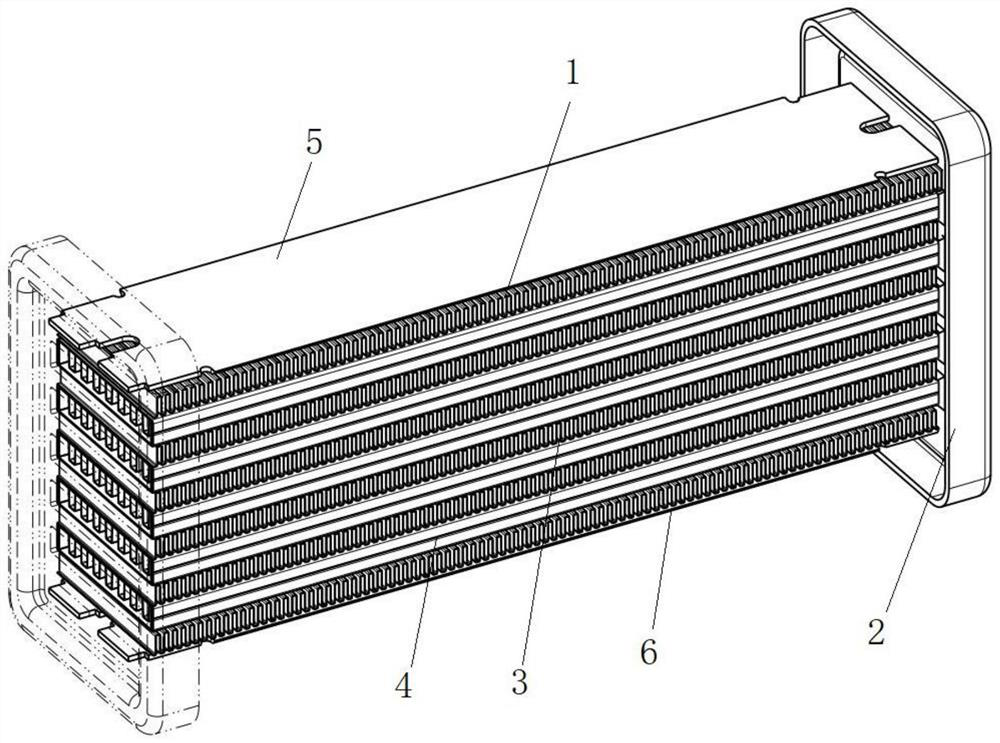

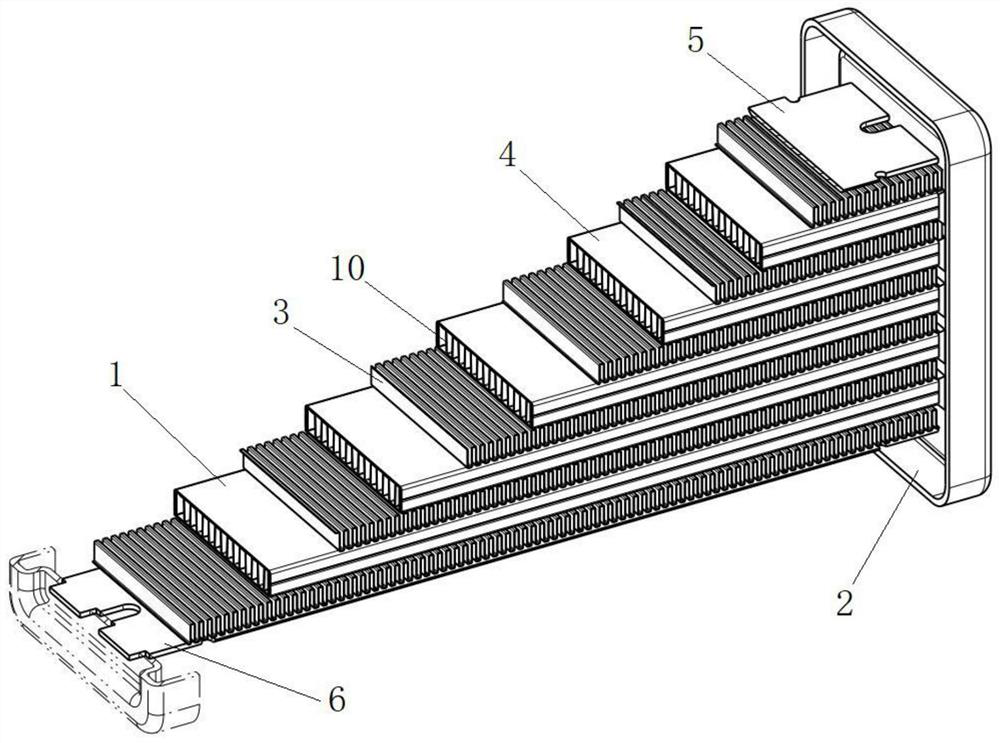

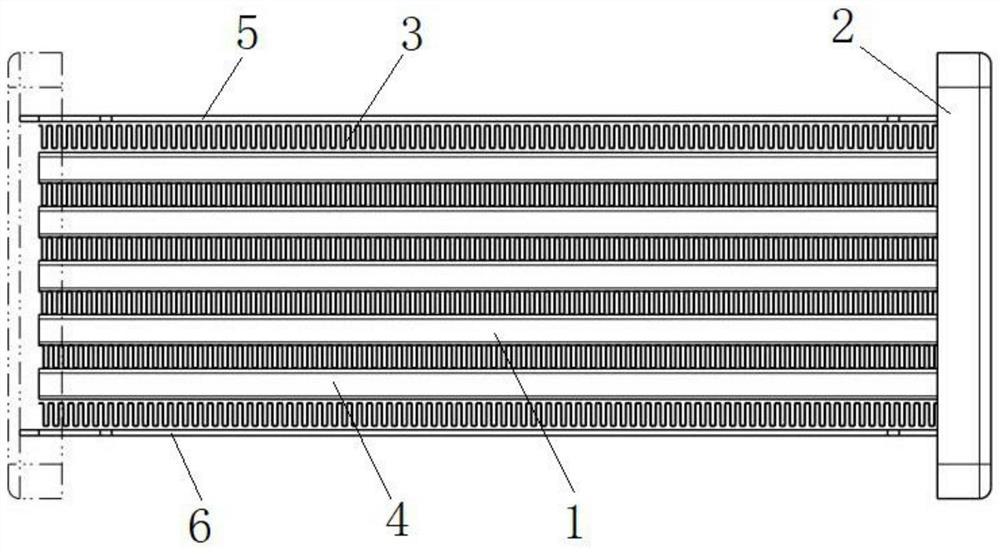

[0050] Such as Figure 1-9 As shown, the oil cooler with ribs in this embodiment includes a body, the body includes a core 1 and a main board 2 welded to both ends of the core 1; the core 1 includes six heat dissipation strips 3 and Five oil cooler tubes 4, heat dissipation belts 3 and oil cooler tubes 4 are alternately overlapped, the top of the uppermost heat dissipation belt 3 on the core 1 is welded with an upper guard plate 5, and the bottom of the lowermost heat dissipation belt 3 is welded with a lower guard Plate 6; the main board 2 at the left end of the body is provided with oil inlet holes 7 corresponding to the number and positions of the oil cooler tubes 4, and the main board 2 at the right end of the body is provided with oil outlet holes 8 corresponding to the number and positions of the oil cooler tubes 4 .

[0051] The oil cooler tube 4 includes a first tube body 9 and inner fins 10; the first tube body 9 is bent from a whole piece of alloy material, the thic...

Embodiment 2

[0056] Such as Figure 7-10 The difference between this embodiment and Embodiment 1 is that the main body of the oil cooler in this embodiment also includes a mounting base 18, and the top of the mounting base 18 is welded to the bottom plate of the main board 2 and the bottom of the lower guard plate 6 respectively; the mounting base 18 A positioning hole 19 is provided on the top, and a protruding positioning ring 20 is provided at the bottom of the mounting base 18 and around the bottom of the positioning hole 19 .

[0057] Working principle: After the oil cooler of this embodiment is positioned and installed through the positioning hole 19 and the positioning ring 20 on the installation base 18, the lubricating oil to be cooled enters the oil cooler tube 4 from the oil inlet hole 7, and flows from the inner fin 10 The spoiler groove 17 passes through, and the spoiler groove 17 reduces the flow velocity of the lubricating oil, and the lubricating oil exchanges heat with the...

Embodiment 3

[0059] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment uses a second pipe body 21 instead of the first pipe body 9, and the second pipe body 21 is bent into a flat shape from a whole piece of alloy material. Shaped tube body, its thickness, wall thickness and width are consistent with the first tube body 9. A reinforcement piece 22 with a thickness of 0.5 mm is provided on the inner walls of both sides of the second pipe body 21 . The working principle of this embodiment is consistent with that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com