Hydraulic oil pump assembling device for oil extraction machine

A technology for hydraulic oil pumps and assembly devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, liquid variable capacity machinery, etc., which can solve the problems of low assembly efficiency and unsatisfactory effects, and achieve good elastic deformation and the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

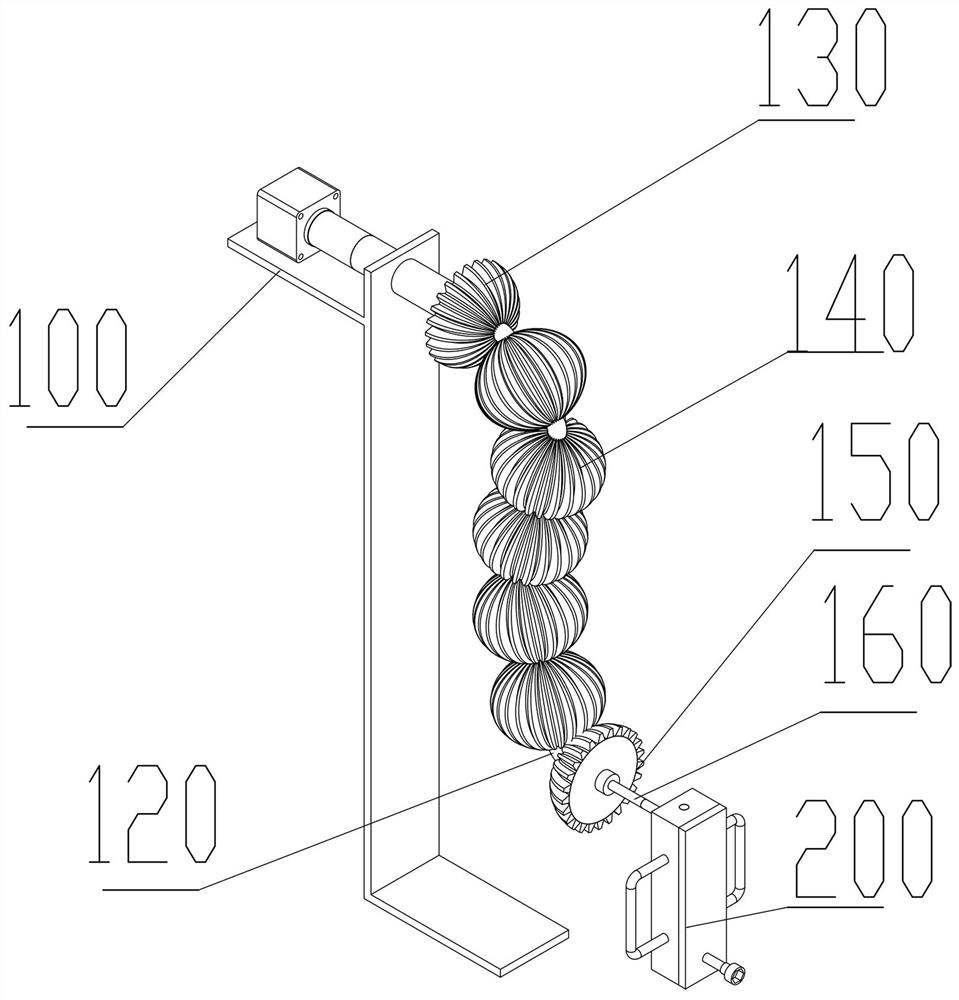

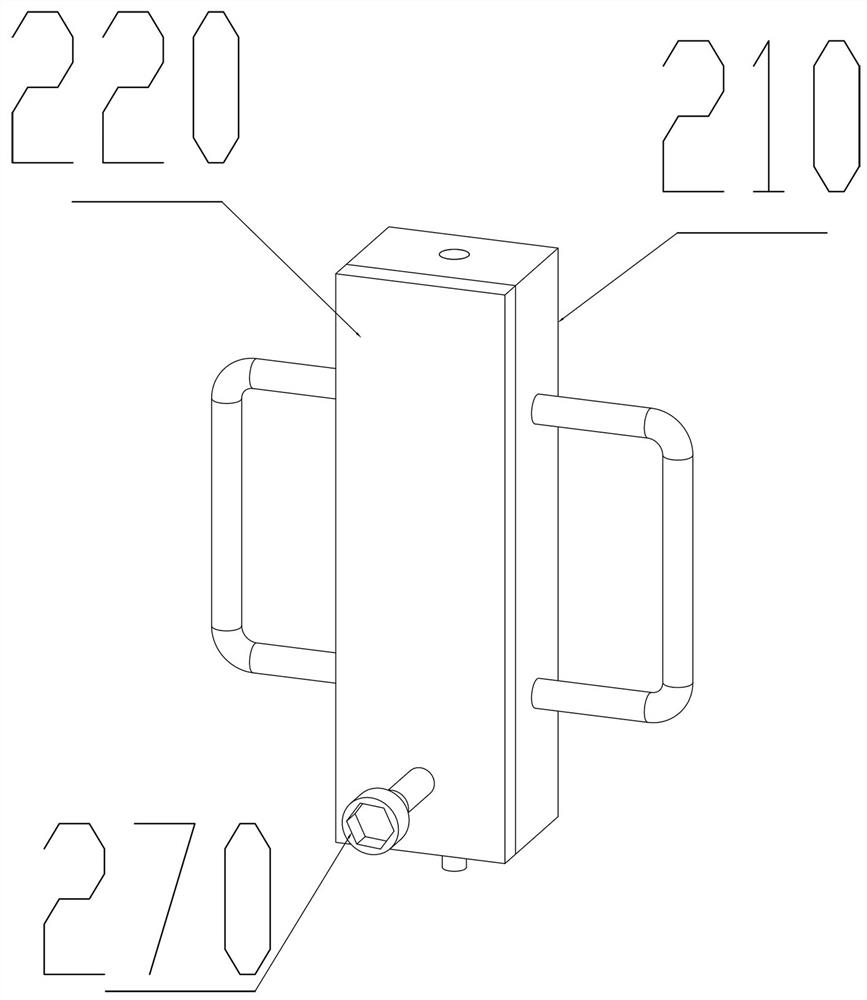

[0026] A hydraulic oil pump assembly device for oil extraction machinery, including a transmission system 100, a tightening device 200, and a torque adjustment device 300. The transmission system 100 includes a frame 110, a tendon flexible shaft 120, a No. 1 ball gear 130, a No. 2 ball gear 140, No. 3 ball gear 150, joint 160, tightening device 200 includes box body 210, case cover 220, No. 1 bevel gear 230, No. 2 bevel gear 240, No. 3 bevel gear 250, No. 4 bevel gear 260, nut sleeve 270, torque The adjusting device 300, the torque adjusting device 300 includes an input shaft 310, an intermediate sleeve 320, an output shaft 330, a spring 340, a pin 350, and a nut 360. The upper part of the frame 110 has a vertical plate 111, and the upper part of the vertical plate 111 has a vertical plate hole 112. There is a motor seat 113 on the upper side of the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com