Wide-load deep-peak-regulation power generation system coupling compressed air energy storage and coal-fired unit

A technology of compressed air energy storage and coal-fired units, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of increasing system coal consumption, uneconomical, slow response to load requests, etc., and achieve load distribution and deep regulation peak demand, improve work efficiency, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

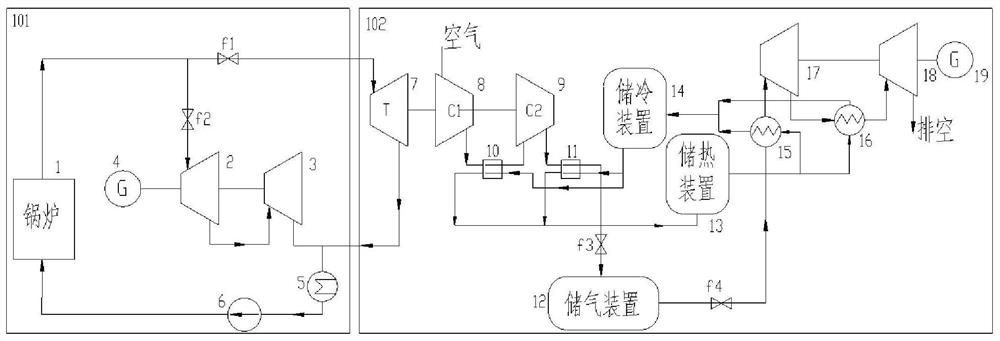

[0065] like figure 1 Shown:

[0066] A wide-load deep peak-shaving power generation system coupled with compressed air energy storage and coal-fired units, including a coal-fired power generation sub-system and a compressed air energy storage sub-system connected to the coal-fired power generation sub-system;

[0067] The compressed air energy storage subsystem includes a steam turbine unit 37, an air compressor system, an indirect cooling system connected to the air compression system, an energy storage system connected to the indirect cooling system, and an energy storage system connected to the energy storage system. A heating system, and an air turbine system connected to the heating system; the steam turbine unit three is connected to the coal-fired power generation sub-system.

[0068] Preferably, the load variation range of the coal-fired power generation sub-system is 5%-100%, and the capacity covers 5MW-1000MW.

[0069] In some possible implementations, the air comp...

Embodiment 2

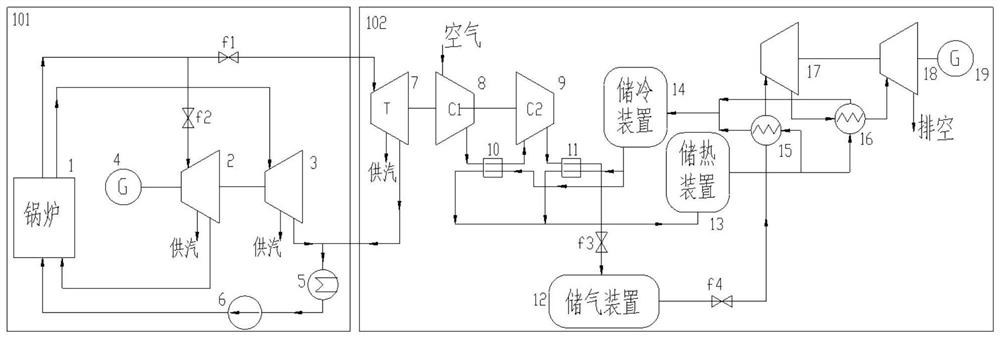

[0088] like figure 2 as shown,

[0089] The difference between this embodiment and Embodiment 1 is that a reheat steam pipeline is set between boiler 1 and steam turbine unit 2 3; a reheat and cold section pipeline is also set between steam turbine unit 1 2 and boiler 1, and the steam turbine is canceled The connecting pipe between unit one 2 and steam turbine unit two 3.

[0090] In this embodiment, the reheat cold section pipeline and the reheat steam pipeline are added. When the coal-fired power generation sub-system is operating at low load, the steam turbine unit 37 in the compressed air energy storage sub-system can undertake industrial steam and supply. The task of heating steam can effectively guarantee the industrial gas and heating steam during the low load of the system and the operation of frequency modulation and peak regulation.

[0091] Other parts of this embodiment are the same as those of Embodiment 1, so they will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com