Chemical fiber filament post-processing system with diversified winding and use method

A chemical fiber and filament technology, which is applied in the field of chemical fiber filament post-processing system, can solve the problems of disrupting production continuity and occupying a large space, and achieve the effects of small space occupation, smooth operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

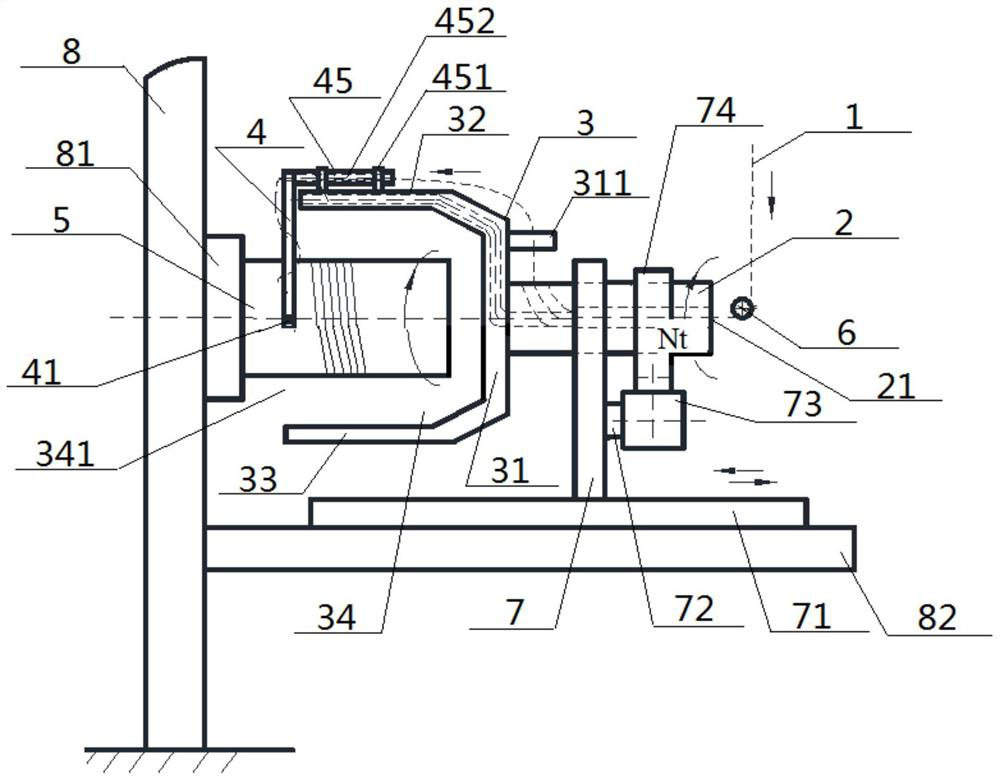

[0057] see figure 1 — Figure 8 , a post-processing system for chemical fiber filaments with various windings, the post-processing system includes a wire drum 5, a guide rod 4, a rotating pin 45, a twisting frame 3 and a rotor 2, and the twisting frame 3 includes a drive The rod 31, the screw rod 32 and the auxiliary rod 33, the two ends of the driving rod 31 are respectively connected with the inner ends of the screw rod 32 and the auxiliary rod 33. The driving rod 31, the screw rod 32 and the auxiliary rod 33 are surrounded by a total of One end of the wire drum 5 is arranged inside the frame inner cavity 34, and the other end of the wire drum 5 passes through the cavity opening 341 of the frame inner cavity 34 and extends to the end of the frame inner cavity 34. Externally, the outer side of the middle part of the driving rod 31 is connected with the inner end of the rotor 2, the outer end of the rotor 2 extends outward, and one end of the wire drum 5 is arranged opposite ...

Embodiment 2

[0060] The basic content is the same as that of Example 1, except that:

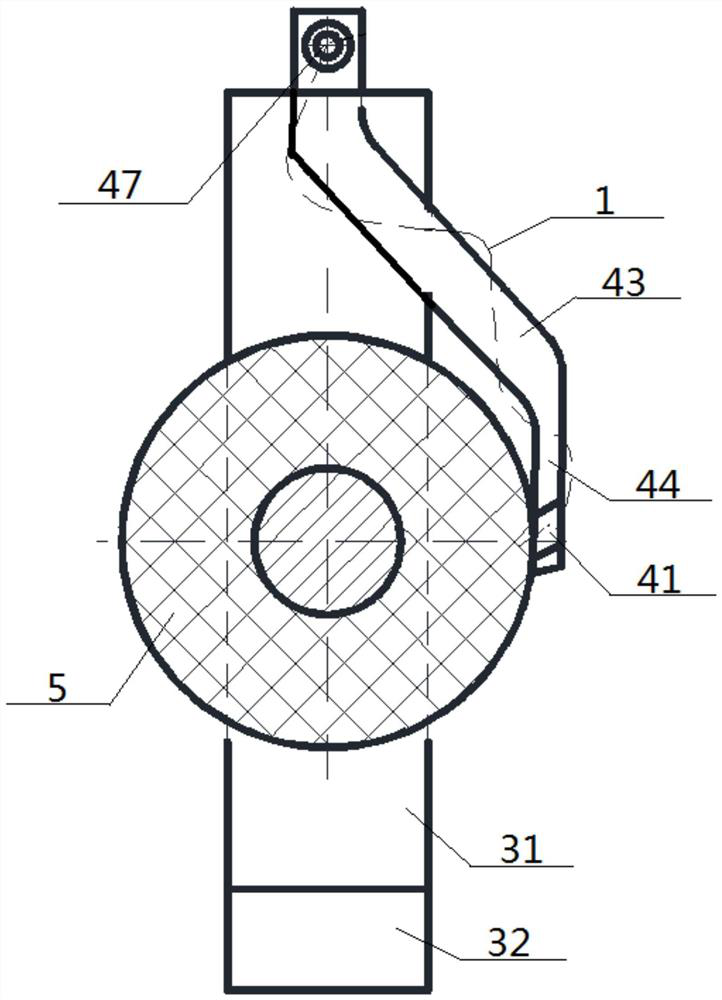

[0061] Structurally: the inside of the rotating pin 45 is provided with a coaxial pin shaft hole 452, and the inside of the connecting part of the guide screw 4 with the rotating pin 45 is provided with a rod shaft hole 47 that communicates with the pin shaft hole 452. .

[0062] Method: After the chemical fiber filament 1 is passed through the guide wire lumen 23 and the guide wire outlet hole 22 in sequence, the chemical fiber filament 1 travels in any of the following ways:

[0063] The first is to pass through the pin shaft hole 452 first, then pass through the rod shaft hole 47, and then wrap around the guide wire rod 4, then pass through the proximal guide wire hole 41, and wind it to the side of the wire cylinder 5 surround;

[0064] The second type is to wrap forward along the lead screw 32 first, then wrap around the lead screw 4 , then pass through the near-tube guide wire hole 41 , and wrap ...

Embodiment 3

[0066] The basic content is the same as that of Example 1, except that:

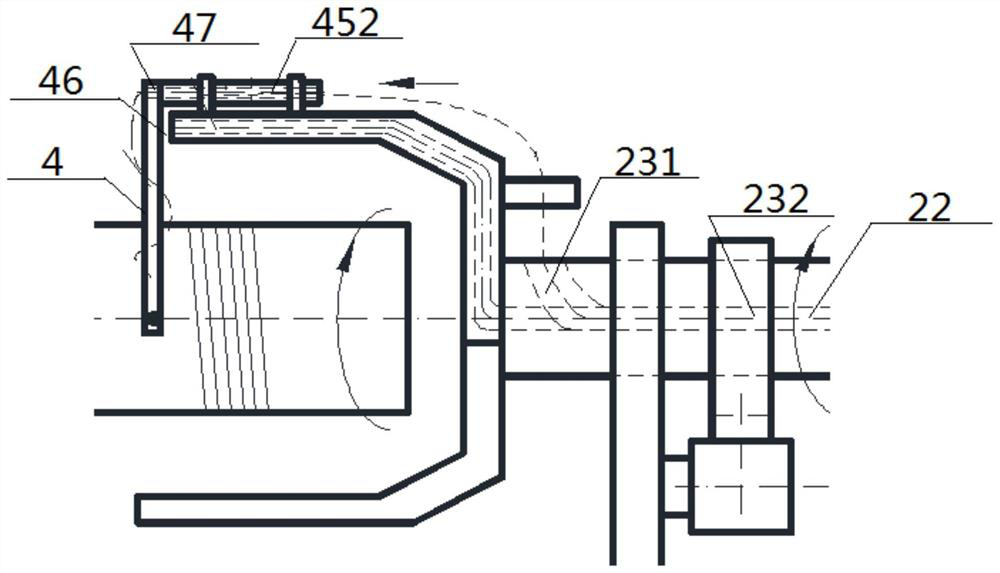

[0067]Structurally: the drive rod 31 is provided with a drive cavity 313, the screw rod 32 is provided with a wire cavity 321, and one end of the screw rod 32 close to the guide rod 4 is provided with a guide wire. The side of the rod 4 is facing the rod outlet 322 , the rod outlet 322 communicates with the guide wire inlet hole 21 through the wire outlet lumen 321 , the driving lumen 313 , and the guide wire lumen 23 in sequence.

[0068] In terms of method: a method of using the above-mentioned post-processing system for chemical fiber filaments with various windings. Then, it passes through the guide wire lumen 23, the driving lumen 313, the wire exit lumen 321, and the rod outlet 322 in sequence, then wraps around the guide wire rod 4, and then passes through the proximal guide wire hole 41, and rolls up Winding around the side wall of the filament drum 5, and then driving the filament drum 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com