Drilling equipment for building construction

A technology for drilling equipment and building construction, applied in drilling/drilling equipment, metal processing equipment, boring/drilling and other directions, which can solve the problems of uneven density, high hardness of steel, and difficult to fix and position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

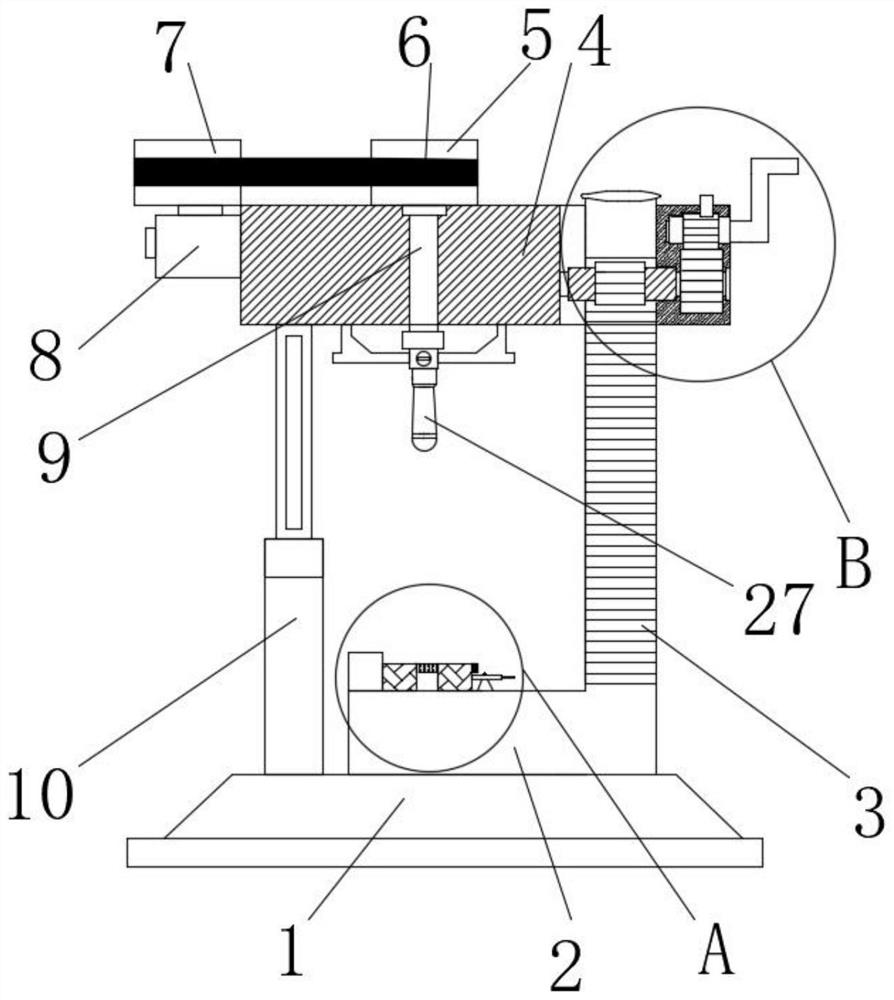

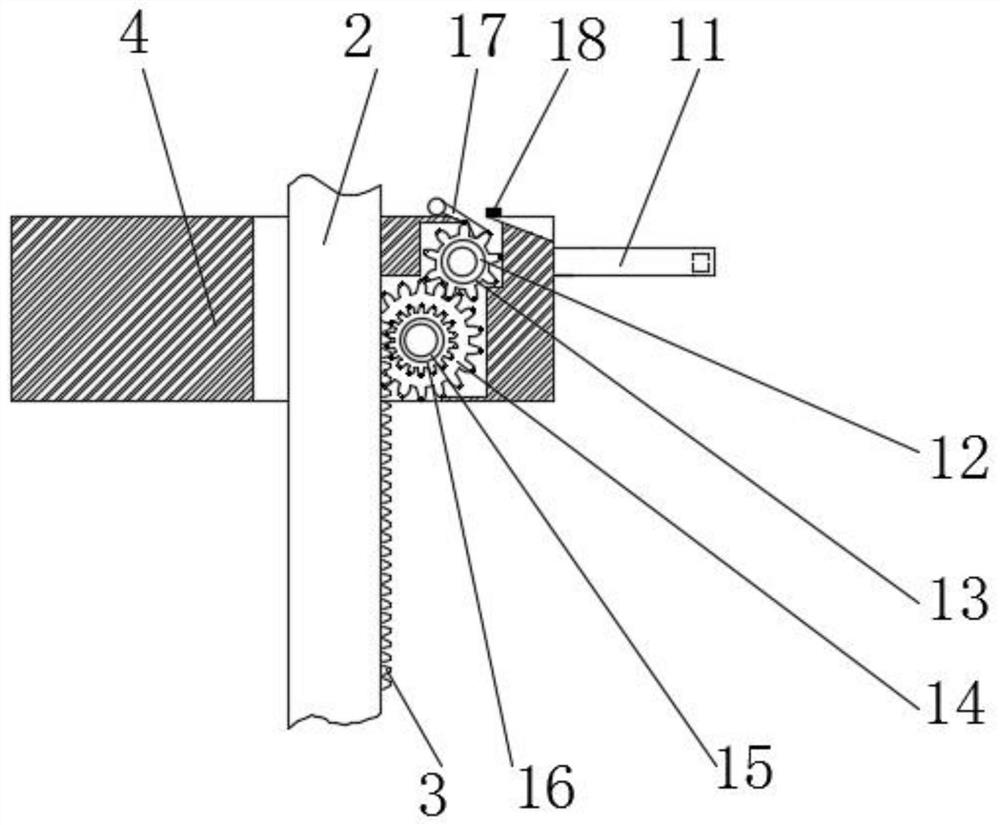

[0026] refer to Figure 1-6 , The drilling equipment used for building construction in this embodiment includes a base 1, a support base 2 is fixedly installed on the top of the base 1, a rack 3 is fixedly installed on one side of the support base 2, and a top plate 4 is arranged above the base 1, The top of the support seat 2 runs through the top plate 4 and is slidably connected with the bottom of the top plate 4. A driving motor 8 is fixedly installed on one side of the top plate 4, and a second pulley 7 is fixedly installed on the output shaft of the driving motor 8. The top of the top plate 4 is rotatably connected with a The first pulley 5, the second pulley 7 and the outer side of the first pulley 5 are covered with the same belt 6, the bottom of the first pulley 5 is fixedly equipped with a drill seat 9, and the bottom of the drill seat 9 runs through the top plate 4 and extends to the top plate 4, the bottom of the drill seat 9 is detachably and fixedly equipped with ...

Embodiment 2

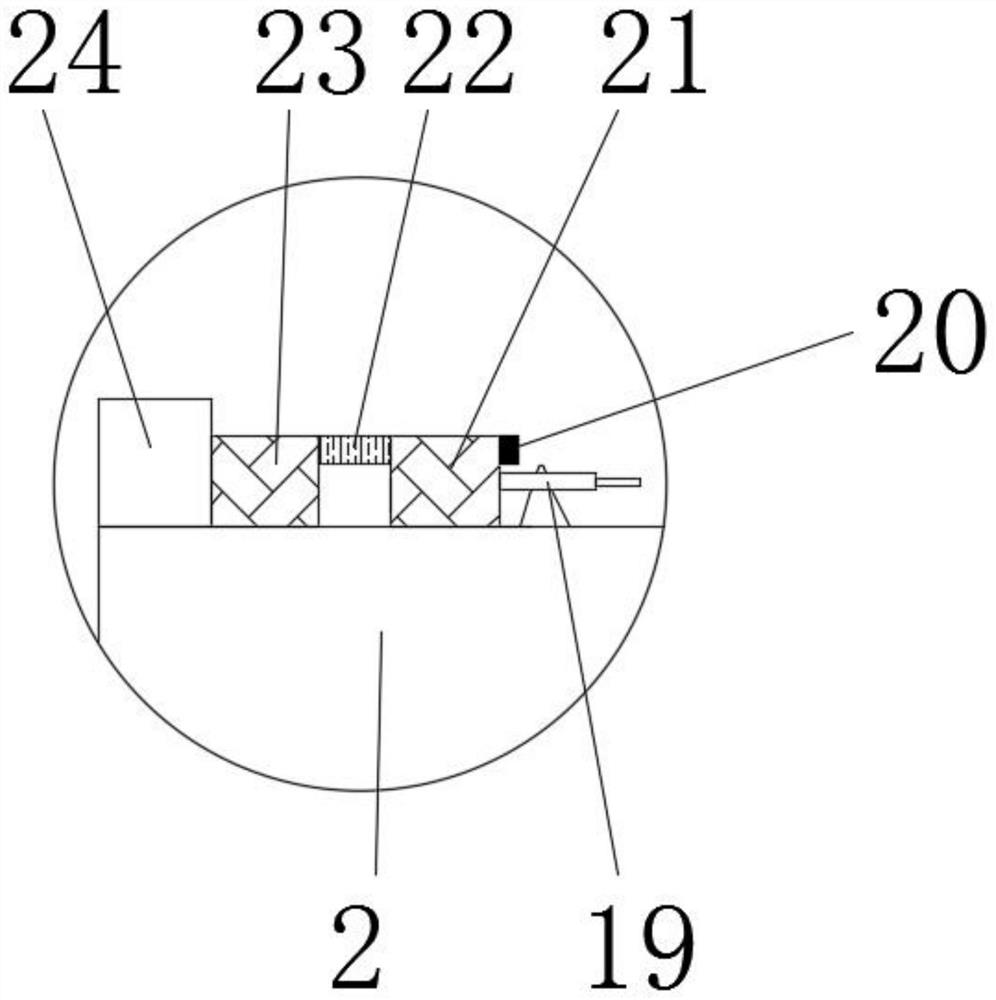

[0028]Improvement is made on the basis of Embodiment 1; the fixing assembly includes a fixing plate 24 fixedly installed on the top of the support base 2, a second clamping block 23 is fixedly installed on one side of the fixing plate 24, and a second clamping block 23 is fixedly installed on one side of the second clamping block 23. The first bolt 22 and the second bolt 25, the top of the support seat 2 is rotatably equipped with an eccentric wheel 19, the top of the support seat 2 is slidably installed with a first clamping block 21, and one side of the first bolt 22 and the second bolt 25 all penetrates The first clamping block 21, the outer thread of the first bolt 22 is connected with the first nut 20, the outer thread of the second bolt 25 is connected with the second nut 26, the top of the base 1 is fixedly installed with the telescopic rod 10, the telescopic rod 10 The top of the top and the bottom of the top plate 4 are fixedly connected, and the one-way brake assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com