Colorful color-changing film

A kind of colorful and color-changing film technology, applied in the field of color-changing film, can solve the problems of reducing product anti-counterfeiting effect and low difficulty of imitation, and achieve the effect of enhancing anti-counterfeiting effect, complex color changing effect and improving anti-counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0036] Such as figure 1 As shown, the multicolor color-changing film provided in this embodiment includes a base film layer 1 , an information layer 8 , a first film layer 2 , an organic layer 3 , a second film layer 4 and a color layer 5 from top to bottom. The surface of the information layer 8 having the micro-nano structure 81 is in contact with the first film layer 2 .

[0037] The base film layer 1 adopts a biaxially stretched polyester film with a thickness of 25um; the material of the first film layer is zinc sulfide, which is produced by vacuum evaporation, and the thickness is 100nm; the material of the organic layer 3 is PMMA (Polymethyl methacrylate, polymethyl methacrylate). methyl acrylate) resin, made by nano-coating process, with a thickness of 100nm; the material of the second film layer 4 is zinc sulfide, made by vacuum evaporation, with a thickness of 100nm; the number of color layers is 1, and the number of color layers The color is black, made by nano-coa...

no. 2 example

[0043] Such as Figure 4 As shown, the difference between the colorful color-changing film provided in this embodiment and the above-mentioned first embodiment is that in this embodiment, the color layer 5 includes three color regions, wherein the color layer 5 includes a first color region 51, a second color region 51, and a second color region respectively. The area 52 and the third color area 53 have different colors in different color areas.

[0044] In this embodiment, the color areas are distributed according to the hollowed-out design of the product pattern. The first color area 51 is black, the second color area 52 is dark purple, and the third color area 53 is dark blue, and the distribution of the color areas corresponds to the desired pattern.

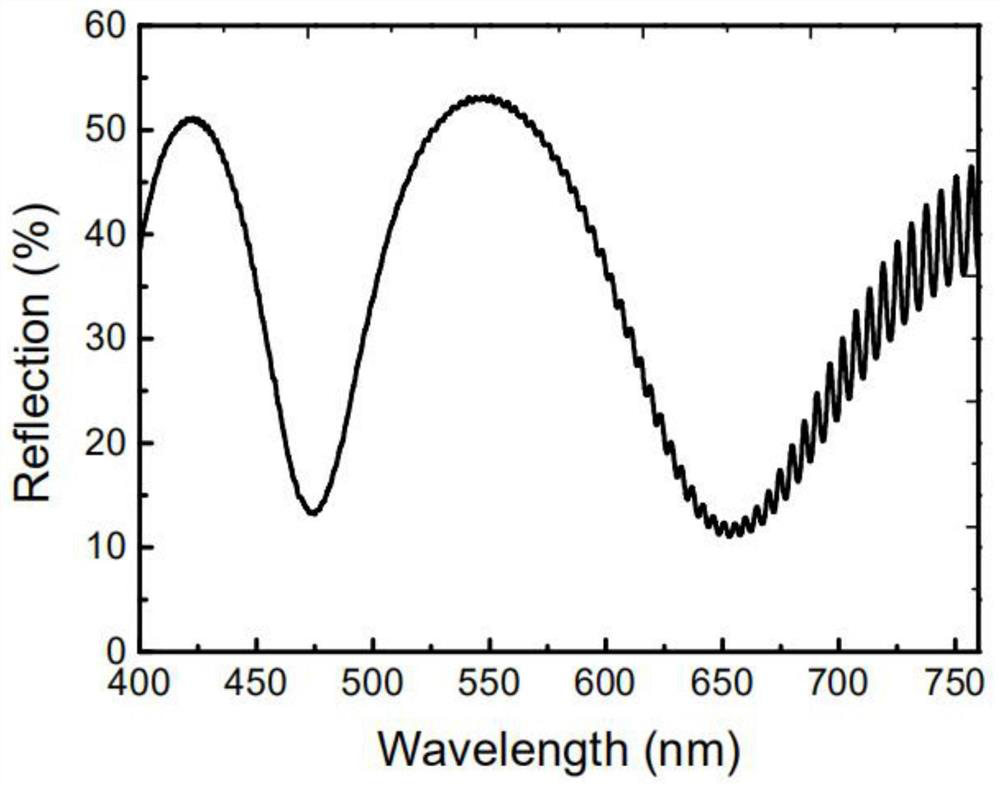

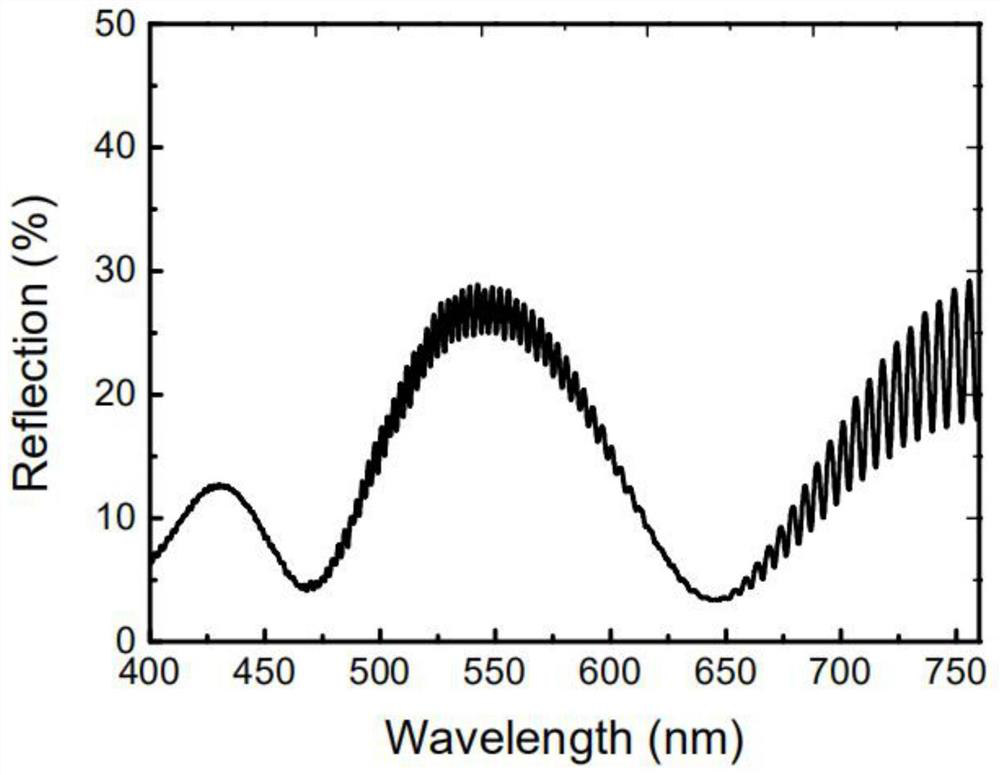

[0045] Such as Figure 5 As shown, the hollow part of the color layer 5 can also achieve the effect of changing the color with the change of the viewing angle due to the slab waveguide resonance structure composed of the fi...

no. 3 example

[0047] Such as Image 6 As shown, the difference between the colorful color-changing film provided in this embodiment and the above-mentioned first embodiment is that, in this embodiment, a release layer 6 and a hot-melt adhesive layer 7 are added to the colorful color-changing film.

[0048] Specifically, the release layer 6 is fixedly laid on the lower surface of the base film layer 1; the information layer 8 is arranged on the lower surface of the release layer 6, and the surface of the information layer with the micro-nano structure 81 is in contact with the first film layer 2 ; The hot melt adhesive layer 7 is fixedly laid on the lower surface of the color layer 5 .

[0049] The release layer 6 is used to facilitate peeling off the base film 1 after hot stamping. Therefore, the release layer 6 after peeling off the base film 1 can be in the outermost layer of the whole colorful color-changing film, and has the effect of protecting the first medium layer 2; certainly, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com