Stiff structure beam-column joint area endless steel plate type stirrup and construction method thereof

A beam-column joint and stirrup technology is applied in the field of ring-belt steel plate stirrups in the beam-column joint area of a stiff structure and its construction field, which can solve the problems of insufficient construction quality, prolonged construction period, inconvenient construction, etc., and achieve accurate and convenient installation. , The effect of improving construction quality and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

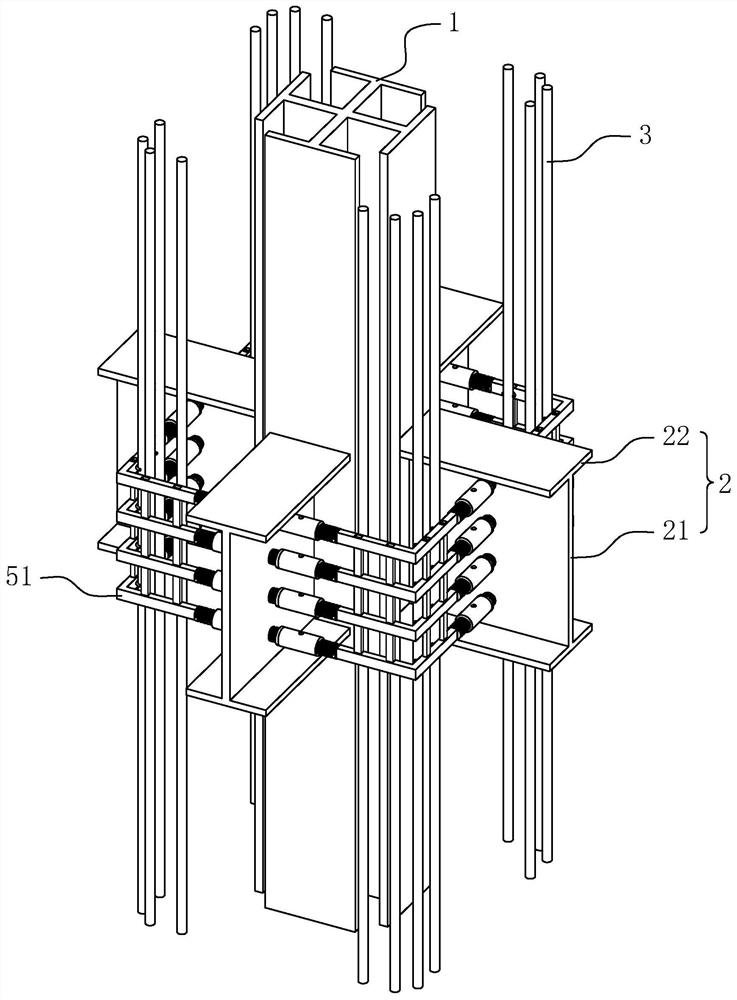

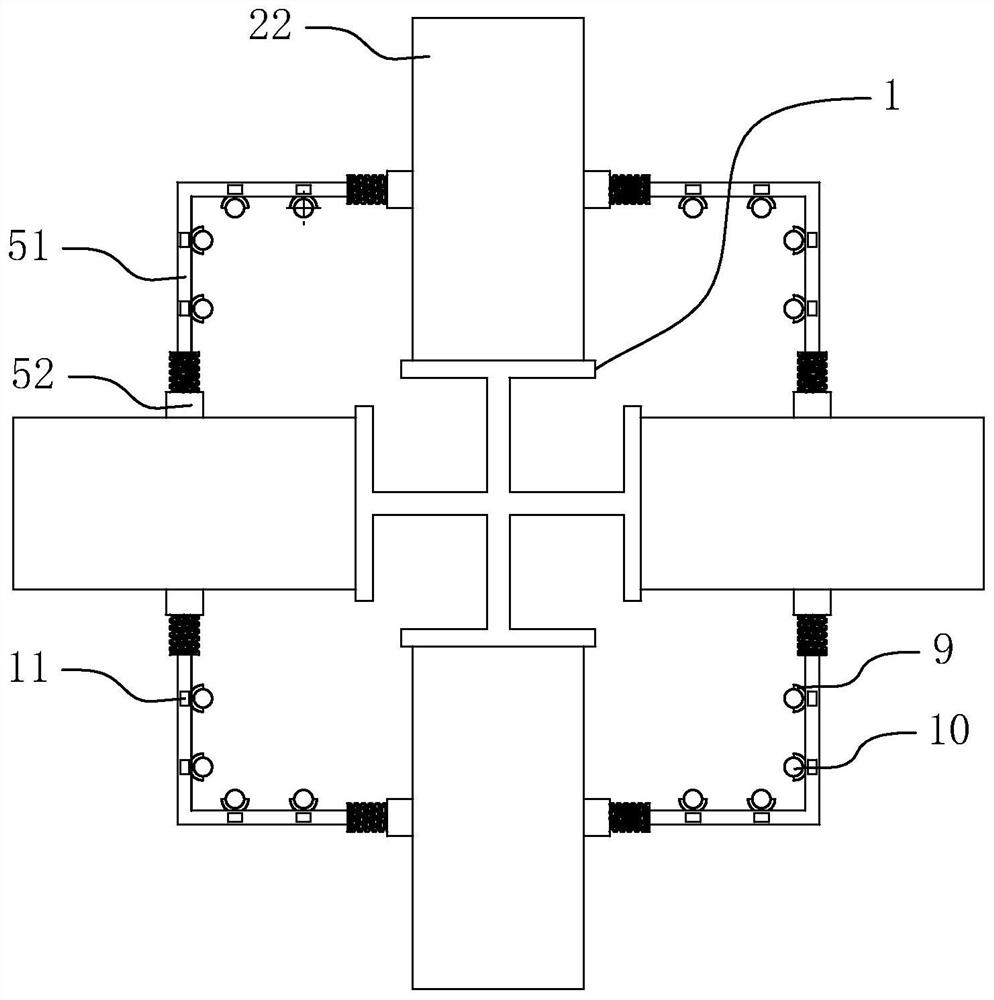

[0041] refer to figure 1 , which is a steel plate type stirrup in the joint area of the beam-column of a rigid structure disclosed in the embodiment of the present application. This kind of ring-band steel plate type stirrup comprises vertically arranged shaped steel column 1, the cross section of shaped steel column 1 is cross-shaped, and beams 2 are horizontally welded on the four vertical sides of shaped steel column 1. Vertically be provided with some longitudinal main ribs 3 around. The beam 2 includes a web 21 arranged vertically to the steel column and a wing 22 fixedly connected to the top and bottom of the web 21 in parallel. The two largest surfaces of the web 21 are vertically arranged, and the web 21 and the wing 22 are close to the steel column 1 One end of each is welded on the steel column 1.

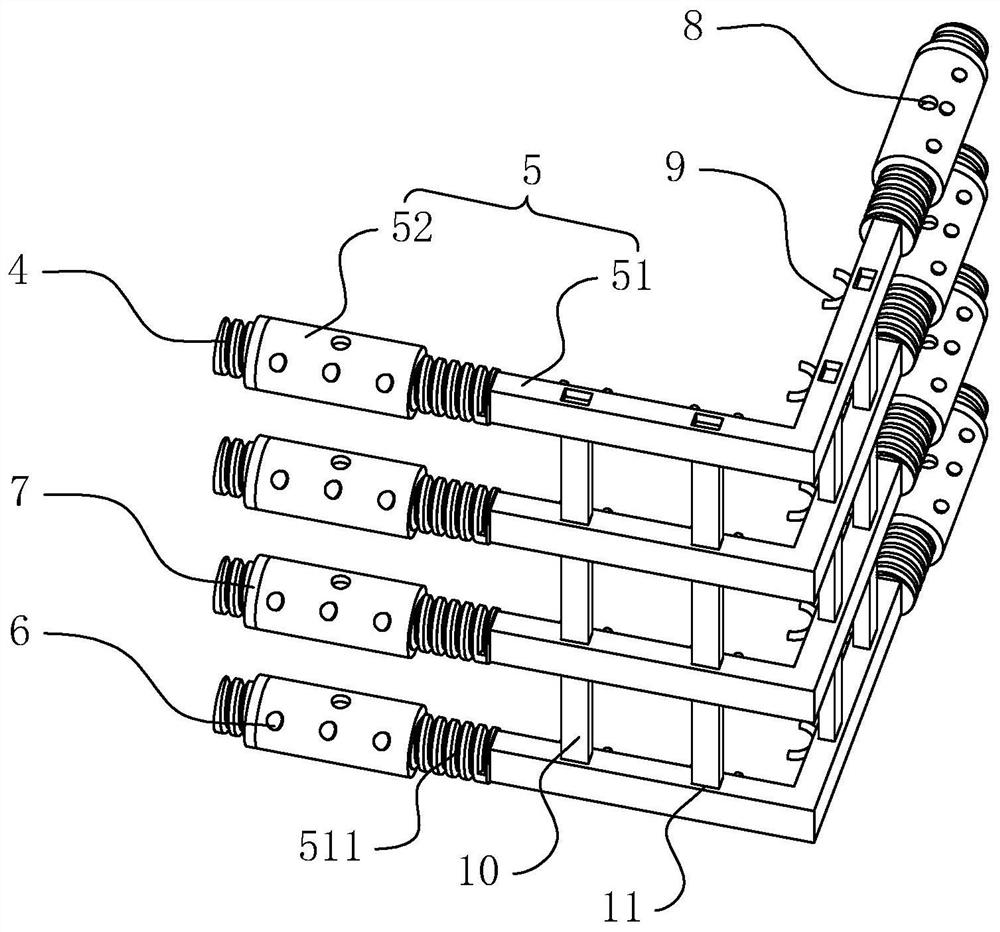

[0042] refer to figure 1 with figure 2 , both sides of the vertical direction of each web 21 are horizontally provided with threaded columns 4, the threaded column...

Embodiment 2

[0047] A construction method for a ring-band steel plate type stirrup in a beam-column joint area of a stiff structure, based on the above-mentioned structure of a ring-band steel plate type stirrup in a beam-column joint area of a stiff structure, comprising the following construction steps:

[0048] Step 1: First install the threaded column on the beam 2 in the factory area, which can be welded or integrally formed;

[0049] Step 2: Use arc welding to first weld the beam 2 on the steel column 1 on the ground, and weld the supporting structure on the steel column 1 to prevent the deformation of the connecting rib 51 when the stirrup structure 5 is installed later. The supporting structure can be For the support plate, it is only necessary that the side of the support plate away from the shaped steel column 1 can abut against the connecting rib plate 51;

[0050] Step 3: Install the stirrup structure 5, specifically: install the stirrup structure 5 from bottom to top, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com