Single crystal furnace positioning mechanism capable of automatically stabilizing seed crystals, single crystal furnace system and stabilizing method

A technology of automatic stabilization and positioning mechanism, which is applied in the direction of single crystal growth, chemical instruments and methods, and self-melt pulling method, etc., can solve the problems of difficulty in ensuring the stability and accuracy of seed crystals, shaking of single crystals, etc., and achieve shortening of invalid working hours, The effect of increasing output and reducing automation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

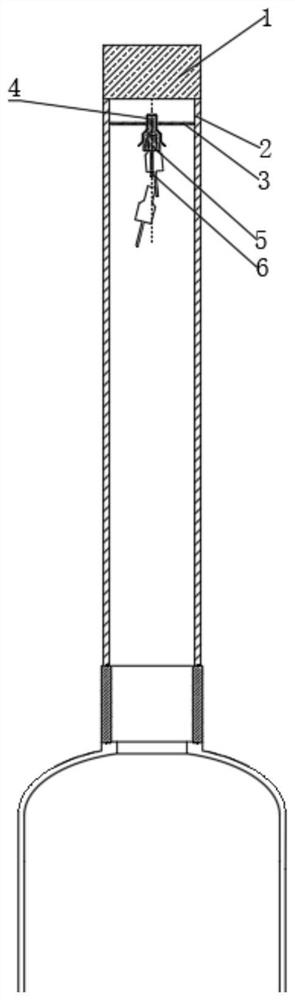

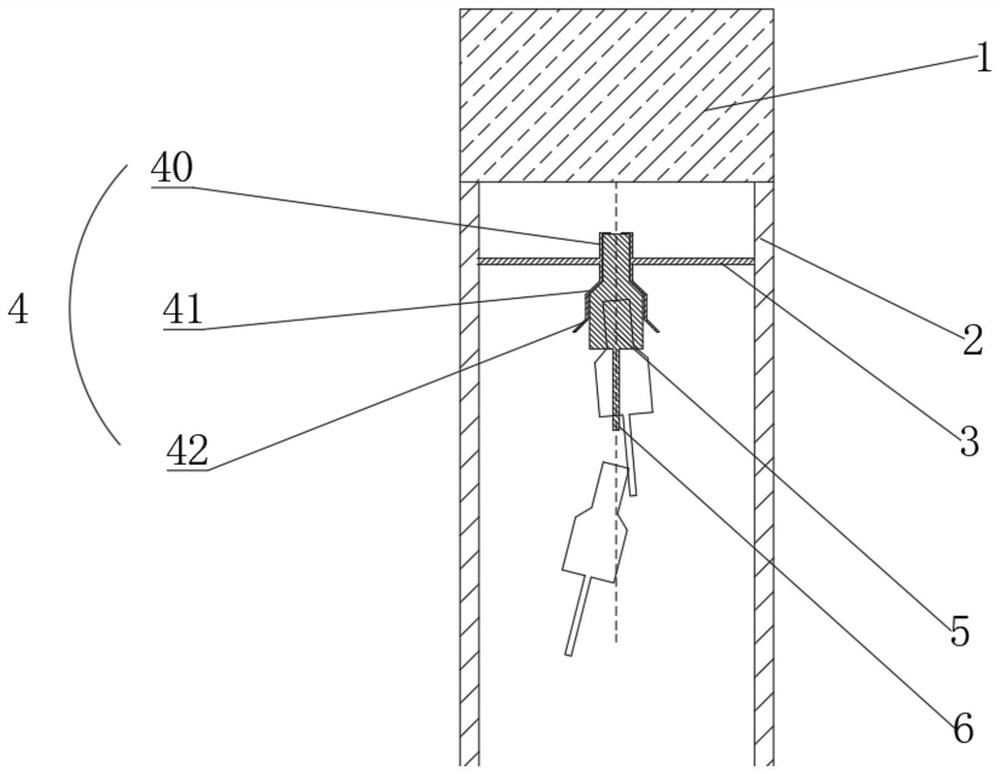

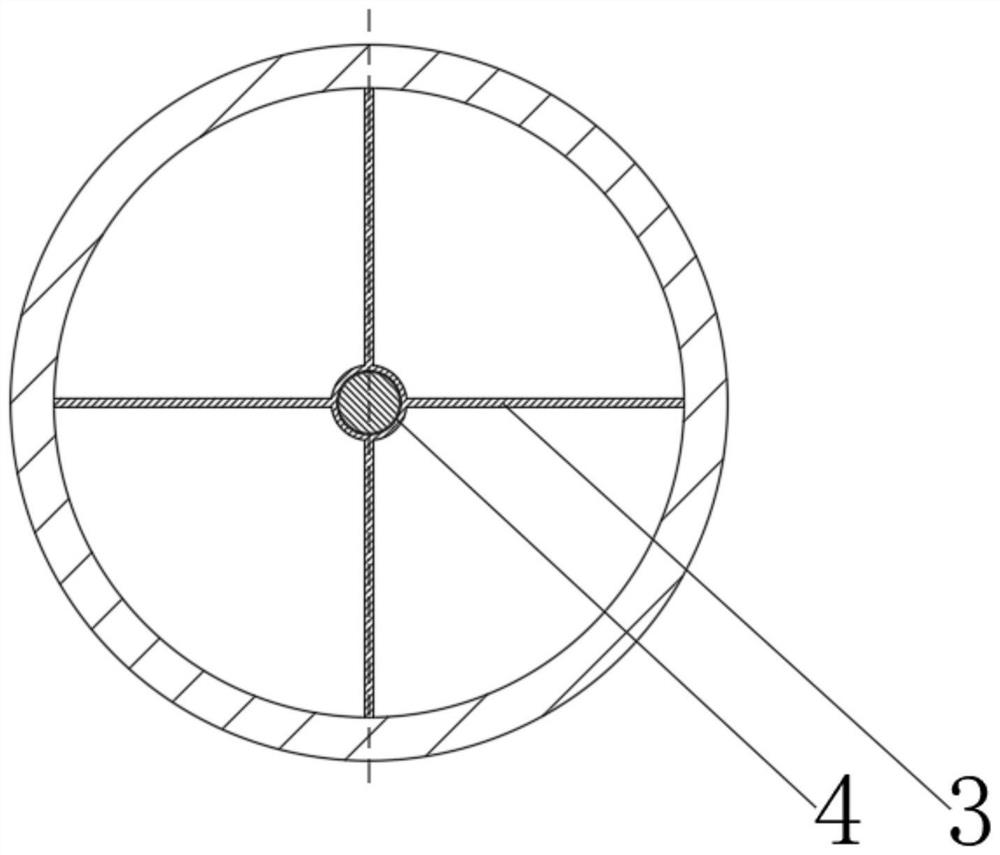

[0038] figure 1 It shows a schematic structural diagram of an embodiment of the present invention, and specifically shows the structure of this embodiment. This embodiment relates to a single crystal furnace positioning mechanism for automatically stabilizing a seed crystal, a single crystal furnace system and a method for Czochralski During the single crystal process, the automatic positioning and seed crystal stabilization are carried out to realize the automatic stabilization of the seed crystal, which reduces the labor intensity and improves the productivity. At the same time, the seed crystal stabilization automation process is performed in the single crystal furnace sub-chamber gyration and the air replacement in the sub-chamber. It is carried out in the protective gas process to realize the seamless connection between the automatic rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com