Edge folding machine for folding type blister packaging box

A packaging box and edge folding machine technology, applied in the field of edge folding machines, can solve the problems of high labor intensity, time-consuming and laborious, unstable production efficiency, etc., and achieve the effects of saving labor, improving assembly efficiency, and reducing repetitive labor rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

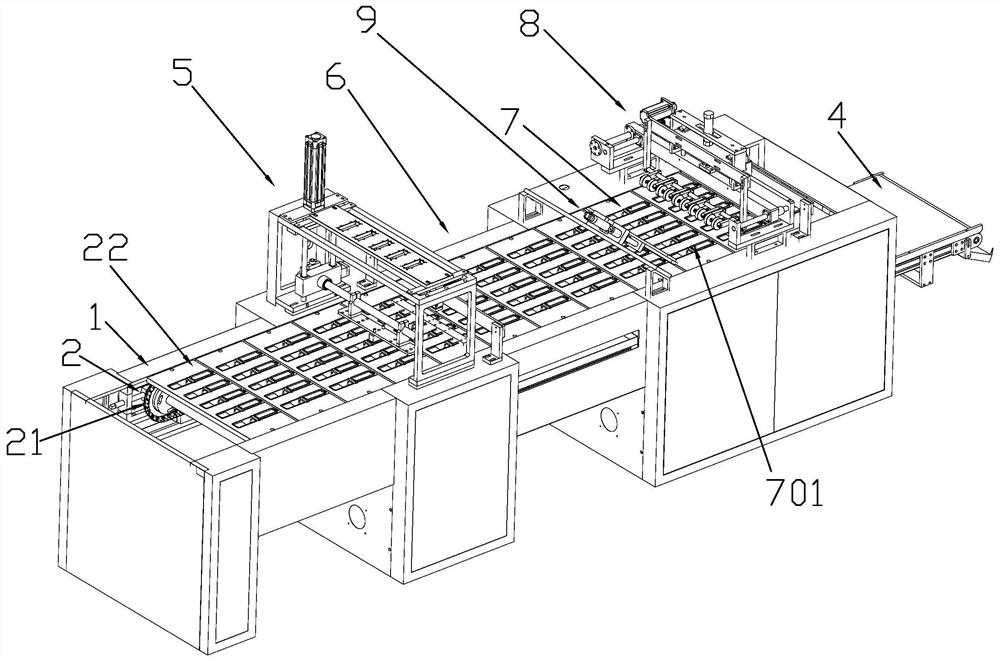

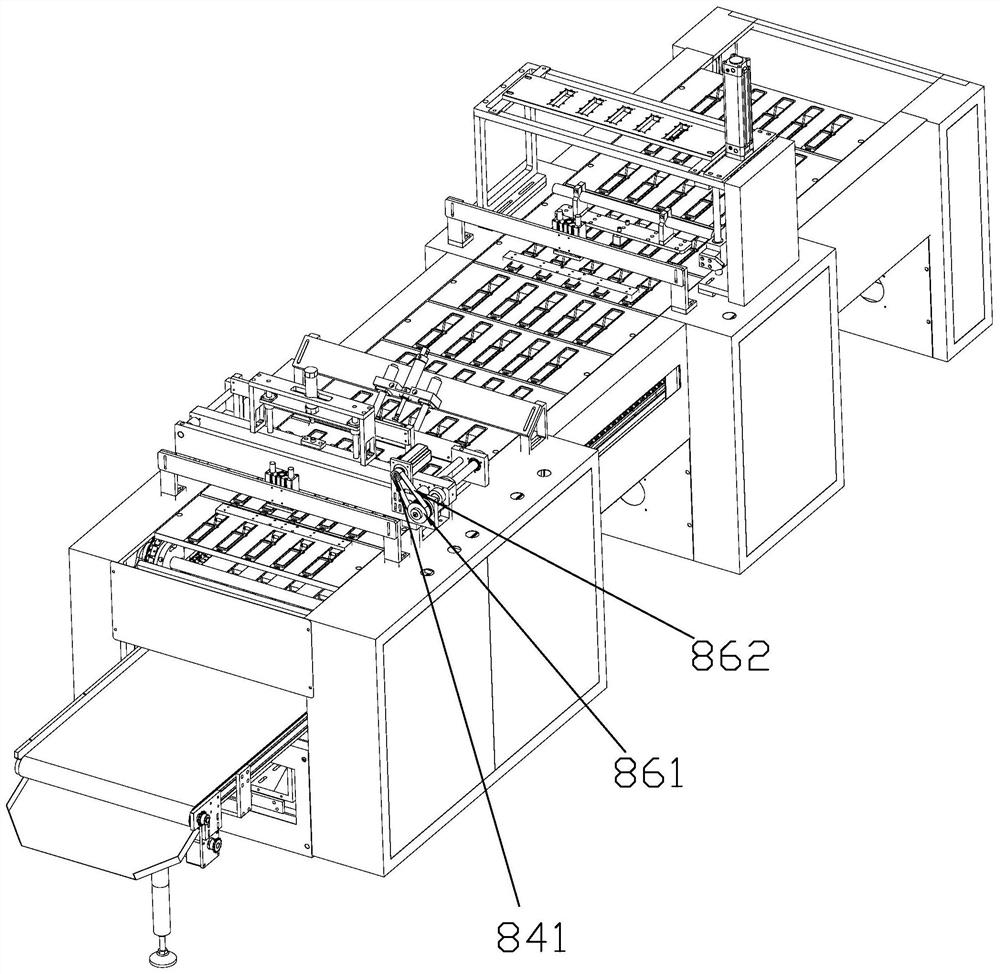

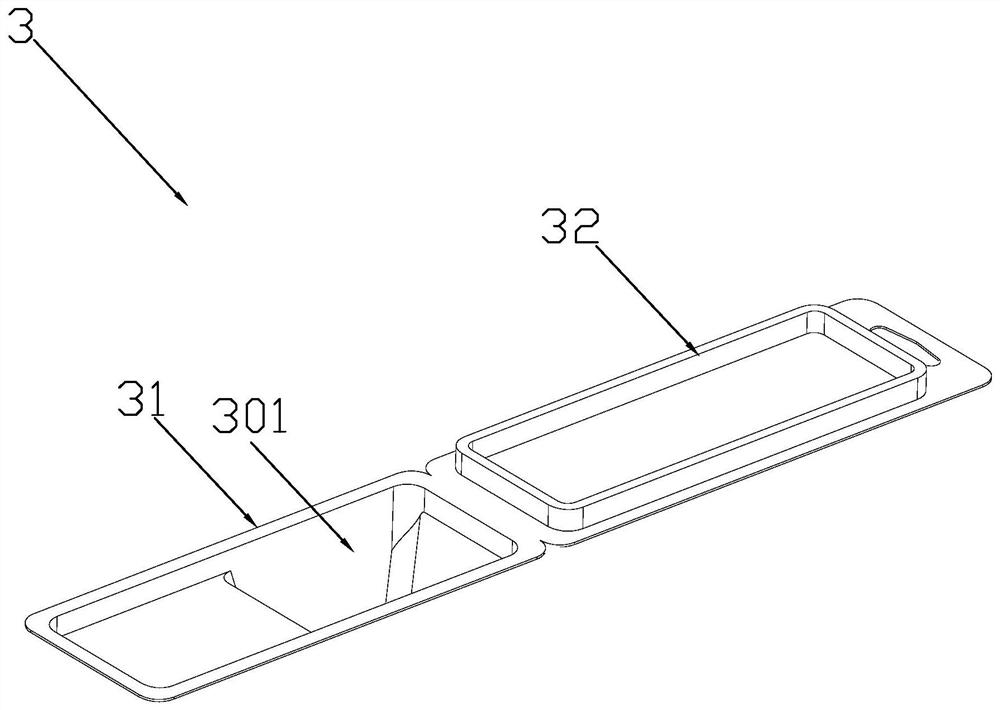

[0032] see Figure 1-Figure 6Shown: The edge folding machine for double-fold blister packaging box, including frame 1, frame 1 is equipped with conveying mechanism 2 along the horizontal direction, and frame 1 is equipped with finished product output structure 3 at the end of the working direction of conveying mechanism 2 , the conveying mechanism 2 can be a chain-type conveying mechanism, and a plurality of chains 21 are set, and a plurality of conveying stations 22 are arranged on each chain 21, and the half-folded blister packaging box 3 on the conveying station 22 is under the action of the conveying mechanism 2 When moving to the bottom of the frame 1, it will fall on the finished product output structure 4 under the action of gravity, and the finished product output structure 4 will be output. The finished product output structure 4 can be set as a mechanism such as a conveyor belt. The double-fold blister packaging box 3 includes a The box body 31 of the accommodating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com