A method and device for on-site verification of a high-voltage direct current protection system

A protection system, high-voltage direct current technology, applied in the field of electrical engineering, can solve the problems of technical secrecy, inability to verify to the laboratory, no mention of protection action time or timing verification method, etc., to achieve small safety risks and applicable Large, simple wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

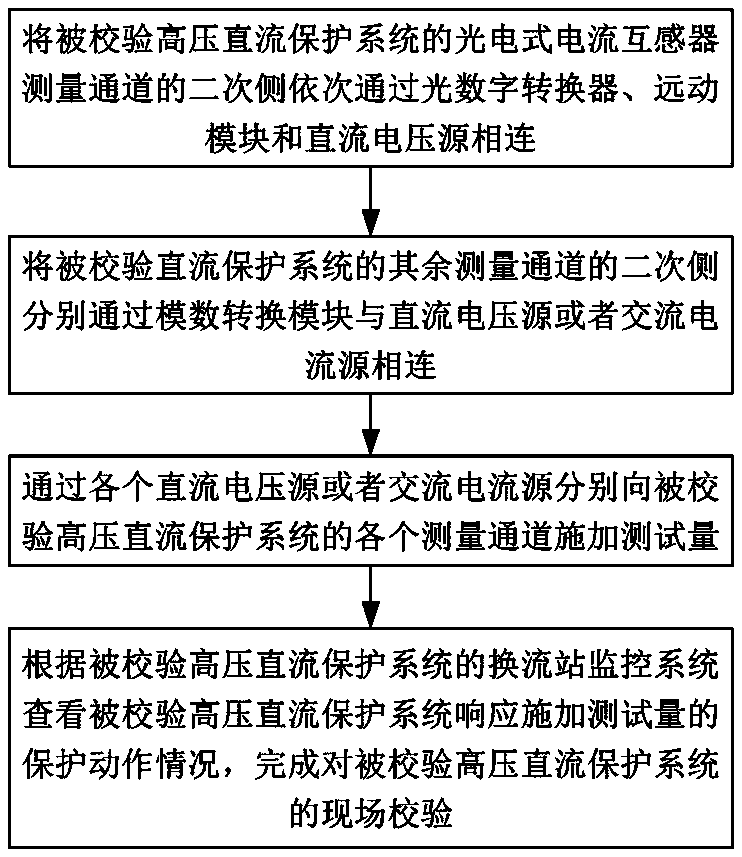

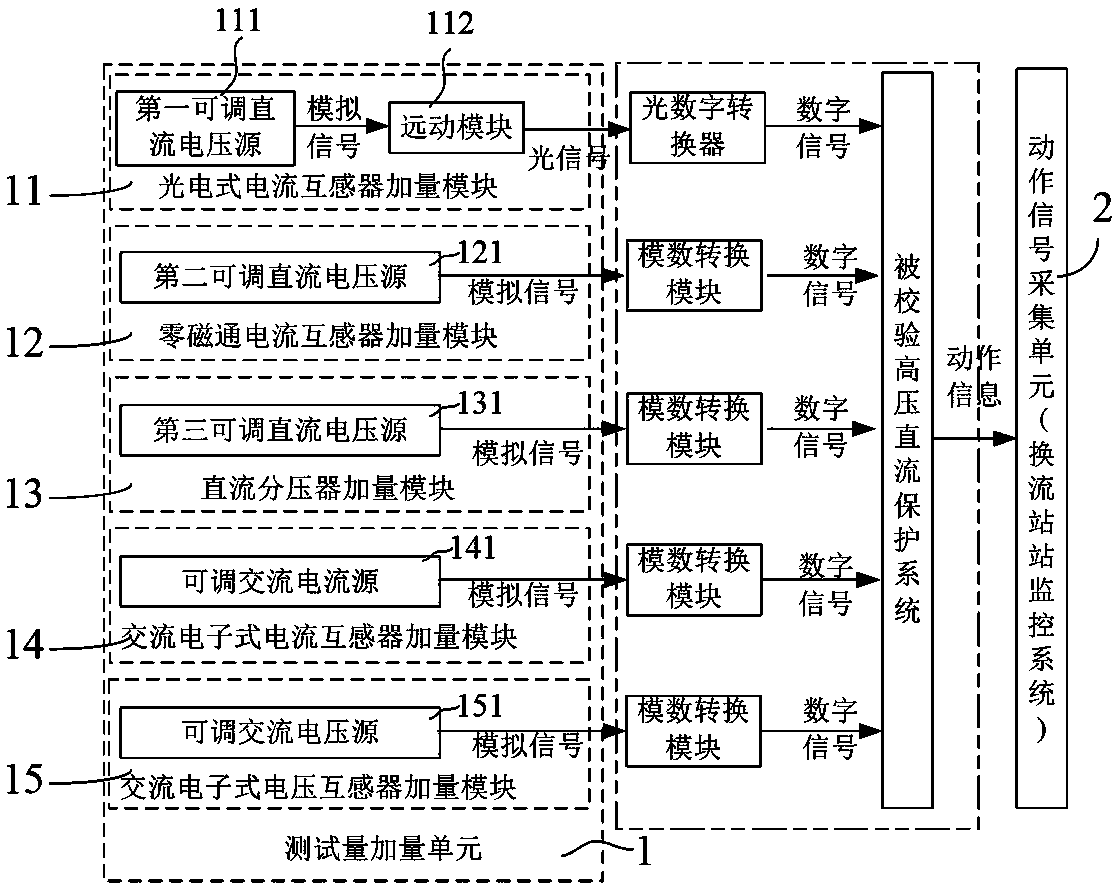

[0041] The following will take the on-site verification work of the verified high-voltage direct current protection system for the pole 1 valve of a ±500kV converter station as an example, to illustrate the on-site verification method and device of the high-voltage direct current protection system of the present invention. The relevant criteria of pole 1 valve DC differential protection only include one photoelectric current transformer measurement channel and one zero-flux current transformer measurement channel. The protection criterion of the pole 1 valve DC differential protection system is divided into two types: alarm and blocking. The alarm criterion is: VDCDP_IVALVE_DIFF > 90A, alarm with a delay of 4s (VDCDP_ALARM); the blocking criterion is VDCDP_IVALVE_DIFF -0.2×IDNC> 1200A, then delay 2ms to switch the system (VDCDP_SS), and then delay 15ms to block DC (VDCDP_TRIP). Among them, VDCDP_IVALVE_DIFF = IDP–IDNC, IDP is the outlet current of the pole bus in the valve hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com