Automatic feeding and discharging orientation device for electronic fuel injection pump aluminum seat of automobile

A technology of orientation device and aluminum seat, which is applied in vibrating conveyors, transportation and packaging, conveyor objects, etc., can solve problems affecting processing efficiency, processing waste products, labor and labor, etc., so as to improve production processing efficiency and stable output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

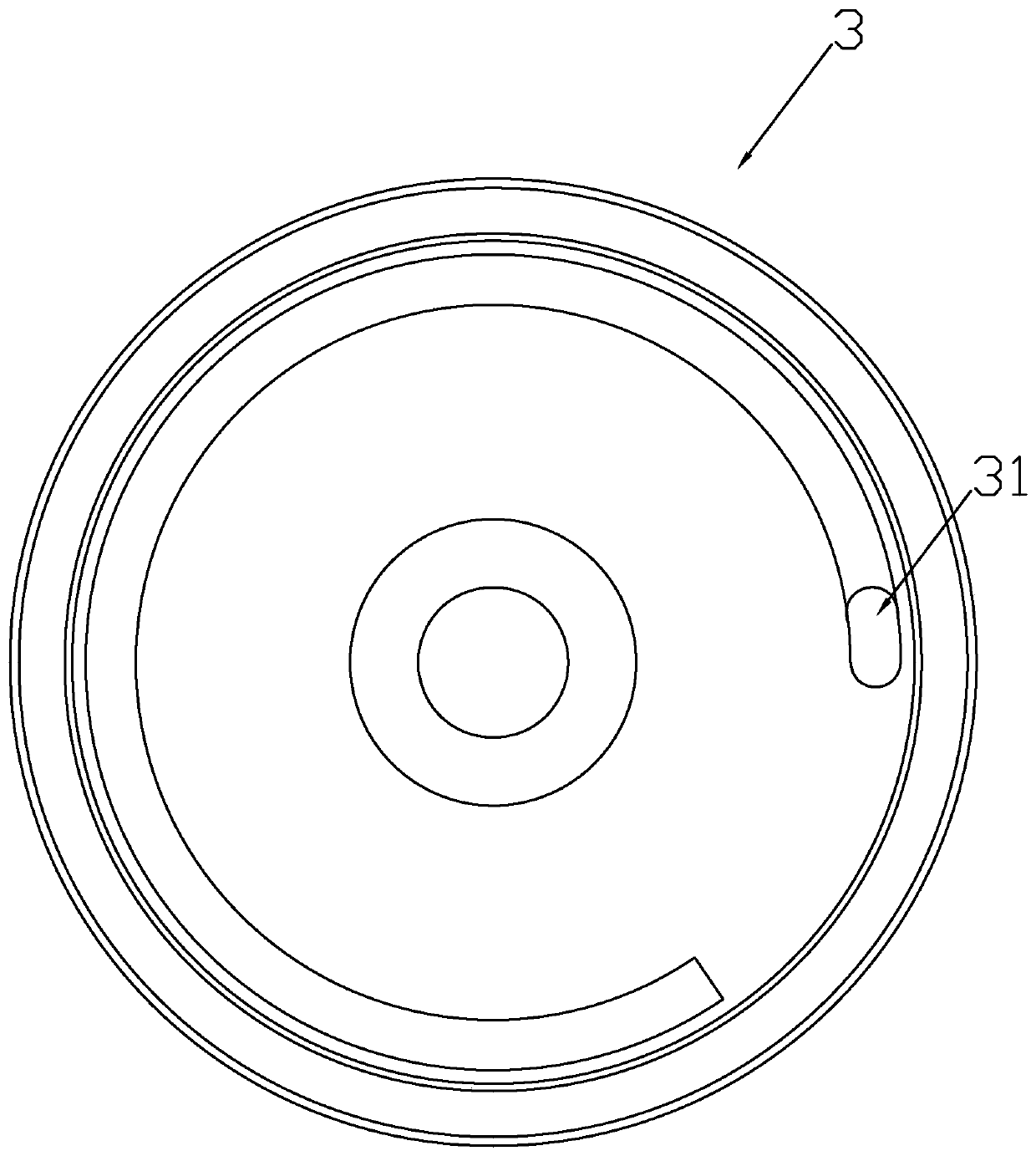

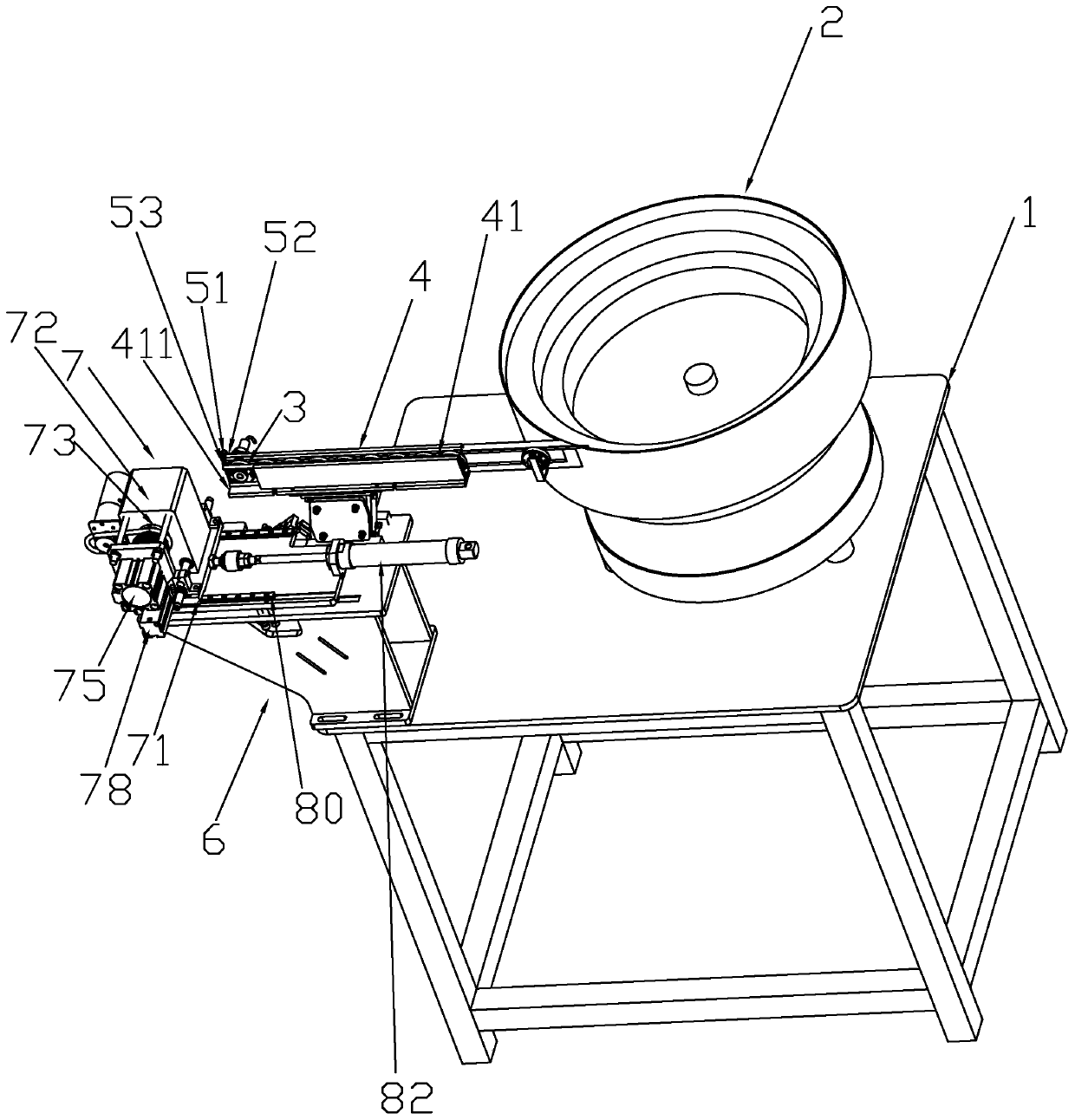

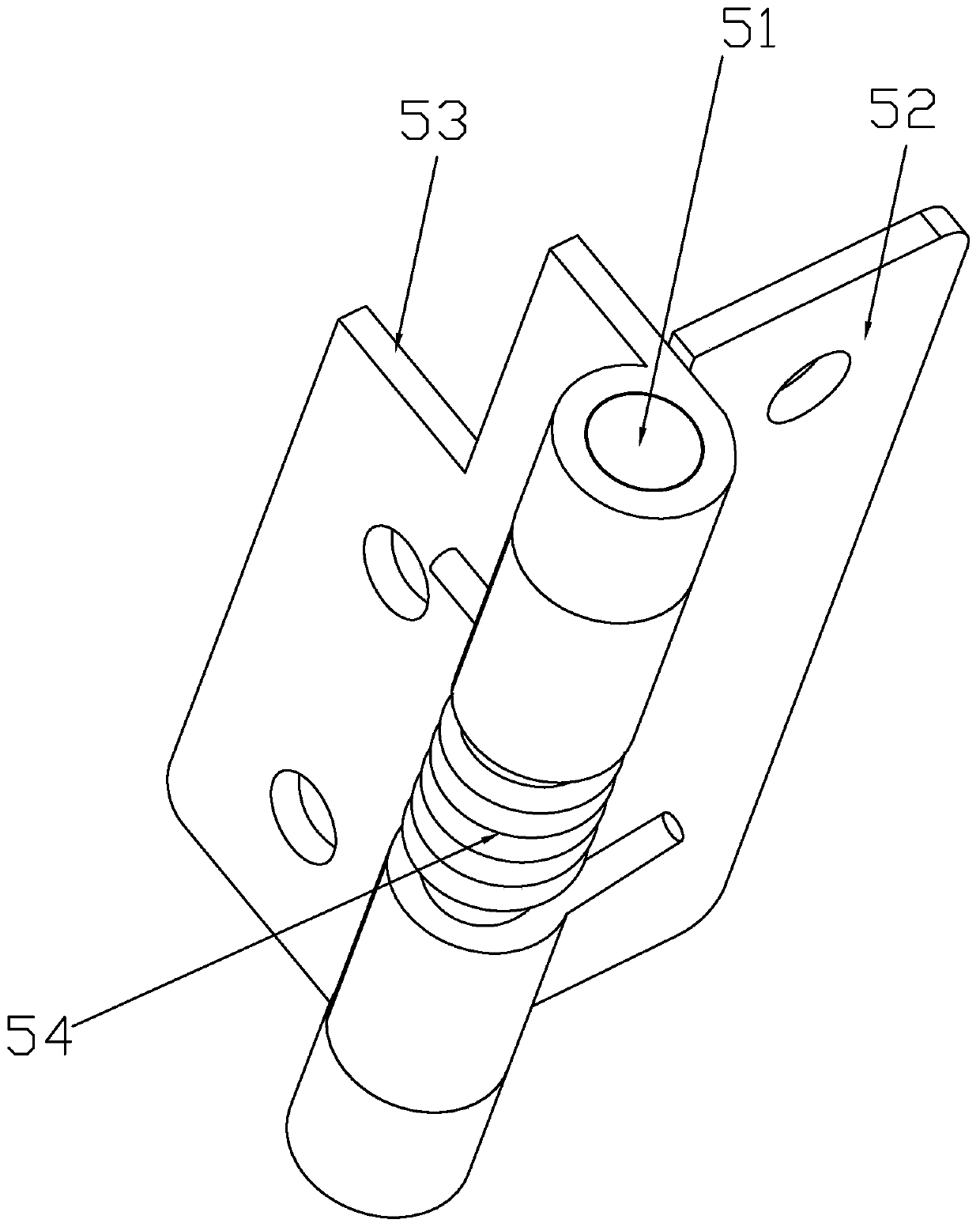

[0020] See Figure 1-Figure 5 Shown: The automatic orientation device for loading and unloading of the aluminum seat of the automobile electric fuel injection pump includes a frame 1, with a vibrating plate 2 set on the frame 1, and a aluminum base 3 to be processed in the vibrating plate 2, and a discharge port of the vibrating plate 2 A discharging rack 4 is provided in the discharging rack 4, and a discharging channel 41 is disposed in the discharging rack 4. The aluminum seat 3 to be processed rolls into the discharging channel 41 from the vibrating disc 2 in turn. The end of the discharging channel 41 away from the vibrating disc 2 is the discharging end 411, the discharge end 411 is provided with a return baffle. The return baffle includes a hinge shaft 51 and a first hinge 52 and a second hinge 53 arranged on the hinge shaft 51. The first hinge 51 passes The bolts are fixedly installed on the discharge frame 4. The second hinge 53 abuts against the discharge end 411 afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com