A method for improving membrane flux by using micro-stirring

A membrane flux, micro-stirring technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as no prospect of industrial application, inability to adapt to large-scale industrial equipment, complex preparation process, etc. To achieve the effect of a wide range of options, a wide range of applications, flexible and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific process of membrane filtration is as follows:

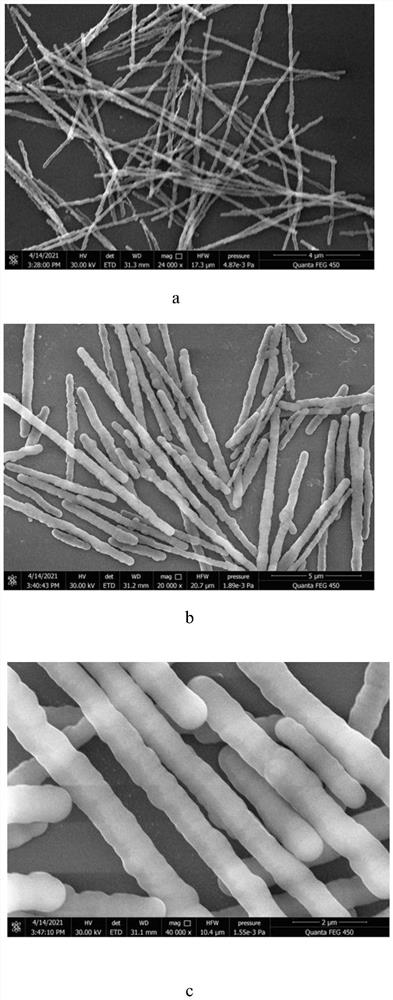

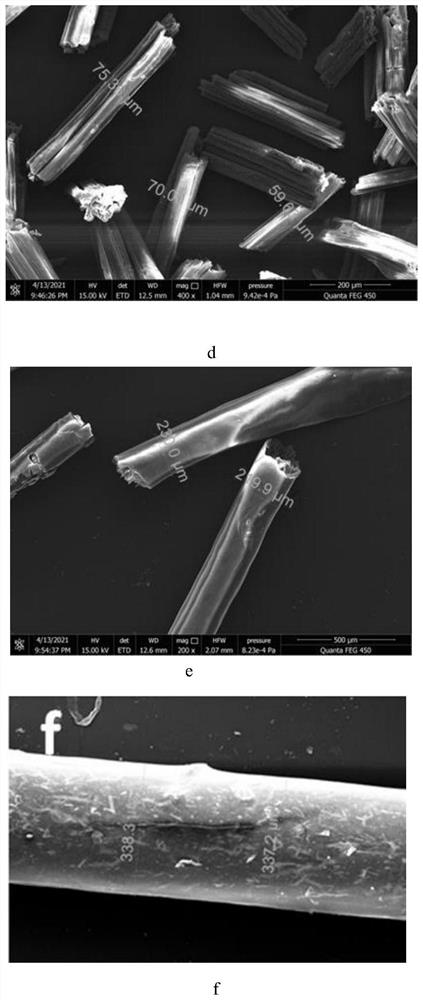

[0039] (1) Add 1 mL of a magnetic stir bar with a diameter of 140 nm to the surface of the nanofiltration membrane in the ultrafiltration cup

[0040] (2) Add 20mL of 5000ppm Na 2 SO 4 For the solution, use a nitrogen bottle to apply a pressure of 0.6 MPa, place a magnetic stirring table under the ultrafiltration cup, rotate at 800 rpm, adopt forward and reverse rotation, and the switching frequency is 1 min.

[0041] (3) The filtered liquid is weighed by an electronic scale, and the sensor on the electronic scale is connected to the flow detection software on the computer to monitor the change of water flux.

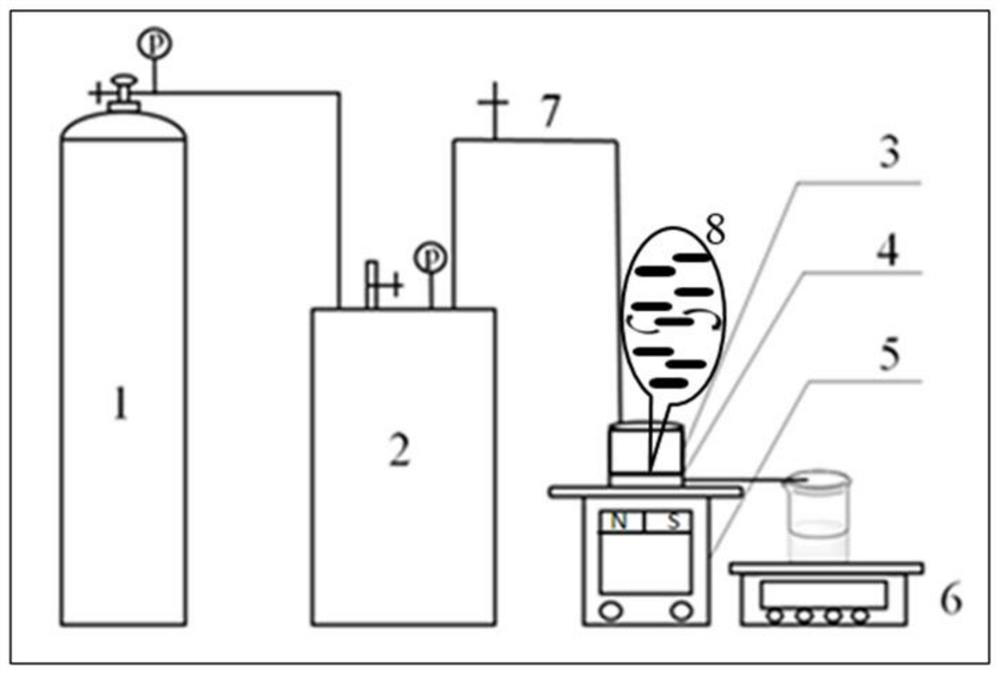

[0042] The specific device can be seen figure 1 : (1) nitrogen cylinder, (2) liquid tank, (3) ultrafiltration cup, (4) diaphragm, (5) magnetic stirrer, (6) electronic balance, (7) valve, (8) in the membrane Surface-rotating nano- or micro-scale stir bars

[0043] The preparation process of the magn...

Embodiment 2

[0048] The specific process of membrane filtration is as follows:

[0049] (1) Add 1 mL of a magnetic stir bar with a diameter of 500 nm to the surface of the nanofiltration membrane in the ultrafiltration cup

[0050] (2) Add 20mL of 5000ppm Na 2 SO 4 For the solution, use a nitrogen bottle to apply a pressure of 0.6 MPa, place a magnetic stirring table under the ultrafiltration cup, rotate at 800 rpm, adopt forward and reverse rotation, and the switching frequency is 1 min.

[0051] (3) The filtered liquid is weighed by an electronic scale, and the sensor on the electronic scale is connected to the flow detection software on the computer to monitor the change of water flux.

[0052] The preparation process of the nano-stirring bar is as follows: add 1 mL of the nano-stirring bar obtained in Example 1, 1 mL of isopropanol, 30 μL of ammonia water, and 10 μL of TEOS into a 4 mL sample bottle, and perform the process of coating while inducing again. After the reaction, centri...

Embodiment 3

[0054] The specific process of membrane filtration is as follows:

[0055] (1) Add 1 mL of a magnetic stir bar with a diameter of 1 μm to the surface of the nanofiltration membrane in the ultrafiltration cup.

[0056] (2) Add 20mL of 5000ppm Na 2 SO 4 For the solution, use a nitrogen bottle to apply a pressure of 0.6 MPa, place a magnetic stirring table under the ultrafiltration cup, rotate at 800 rpm, adopt forward and reverse rotation, and the switching frequency is 1 min.

[0057] (3) The filtered liquid is weighed by an electronic scale, and the sensor on the electronic scale is connected to the flow detection software on the computer to monitor the change of water flux.

[0058] The preparation process of the nano-stirring bar: 1 mL of the nano-stirring bar obtained in Example 1, 1 mL of isopropanol, 30 μL of ammonia water, and 10 μL of LTEOS were added to a 4 mL sample bottle, and the process of coating while inducing was carried out twice. After the reaction, centrif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com