A Shaft Generator with Automatic Switching of Auxiliary Excitation

A shaft generator, auxiliary excitation technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of poor heat dissipation, burn out the user's load, poor cooling effect, etc., to improve the cooling effect and facilitate recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] like Figure 1-Figure 5 As shown, the present invention provides a shaft generator with automatic switching of auxiliary excitation,

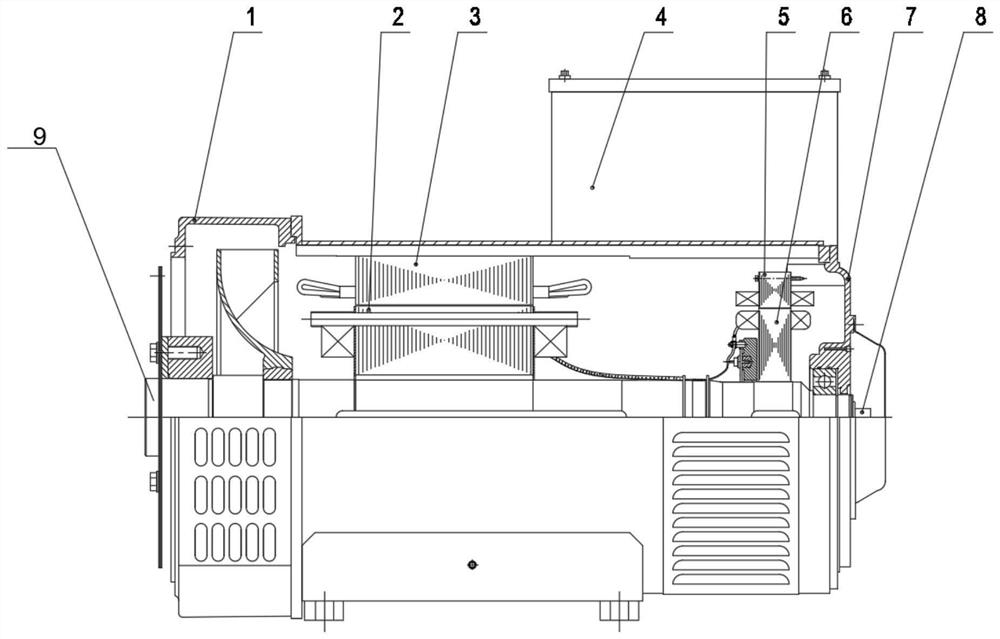

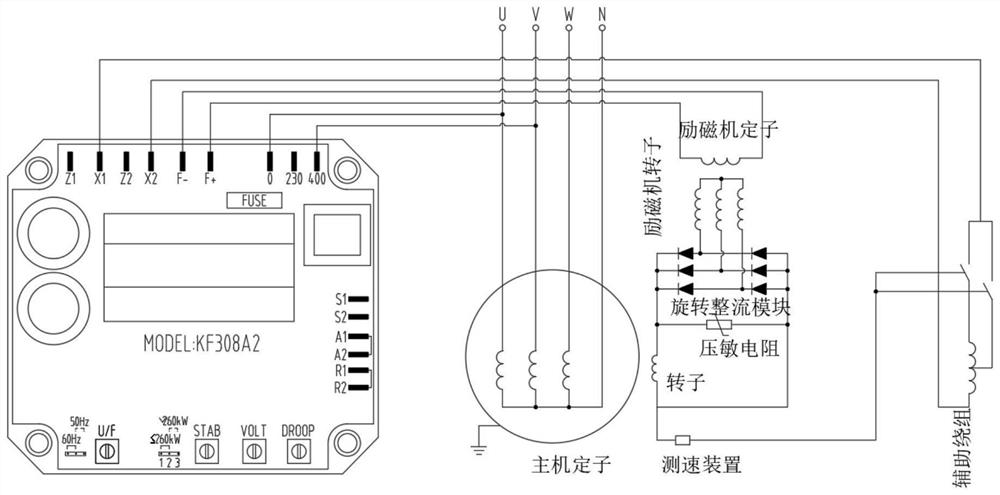

[0029] It includes a shaft generator body 01 and a casing, the shaft generator body 01 is arranged in the casing, and the shaft generator body 01 includes a front end cover 1, a rotor 2, a stator 3, a box 4, an excitation Machine stator 5, exciter rotor 6, rear end cover 7, speed measuring device 8, rotating shaft 9, generator voltage regulator, the speed measuring device 8 is used to detect the rotation speed of the rotating shaft 9, the stator includes stator windings, auxiliary an excitation winding, a switch is electrically connected to the auxiliary excitation winding, and a speed measuring device 8 is electrically connected between the switch and the rotor;

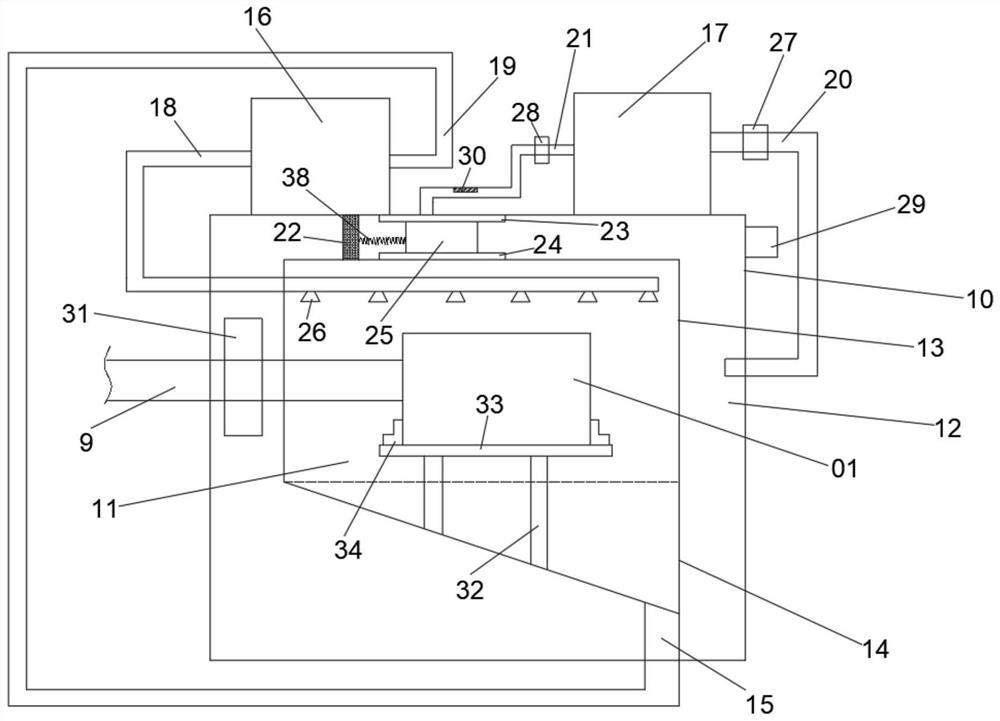

[0030]The casing includes a first casing and a second casing 10. A liquid cooling cavity 11 is formed between the inner side wall of the first casing and the outer side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com