Tobacco primary processing process parameter optimization method based on edge computing

A technology for process parameter optimization and edge computing, applied in computing, manufacturing computing systems, data processing applications, etc., can solve problems such as coordination difficulties, poor real-time data processing, and parameter interaction, achieving high practical value, improving timeliness, The effect of removing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

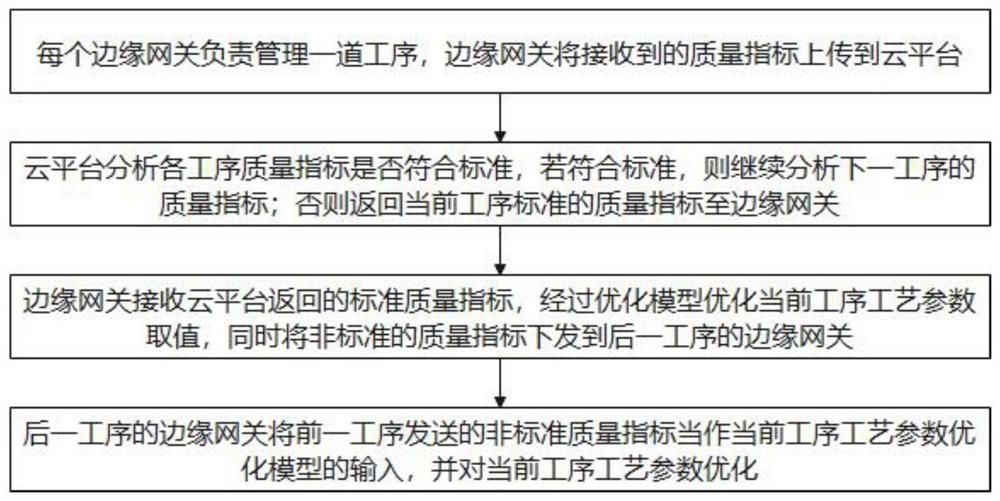

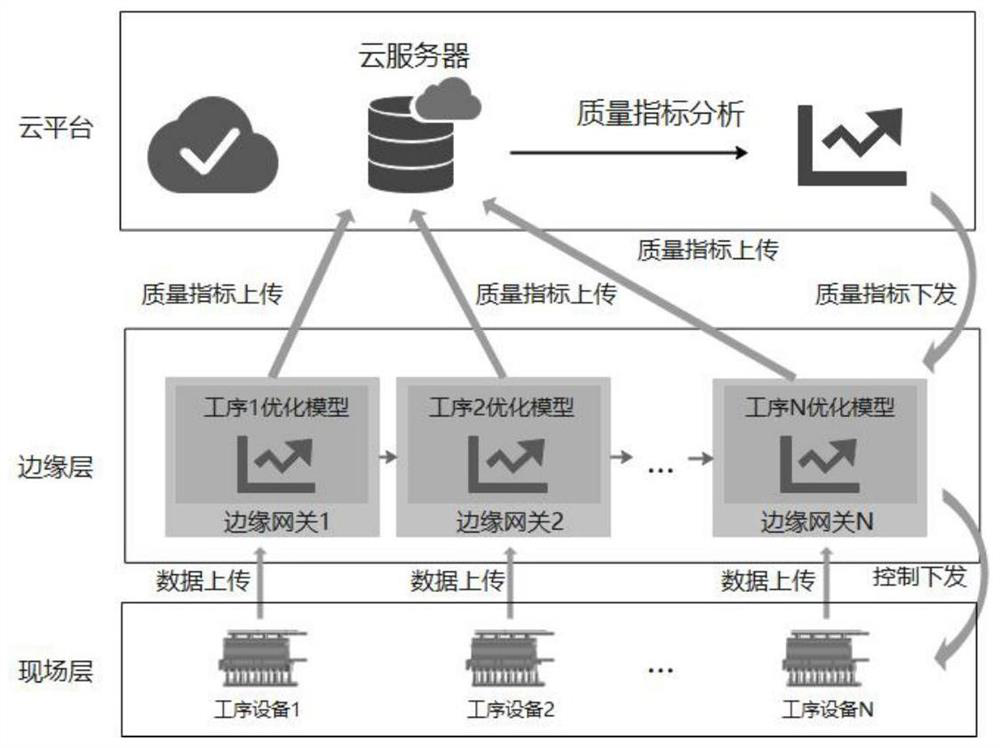

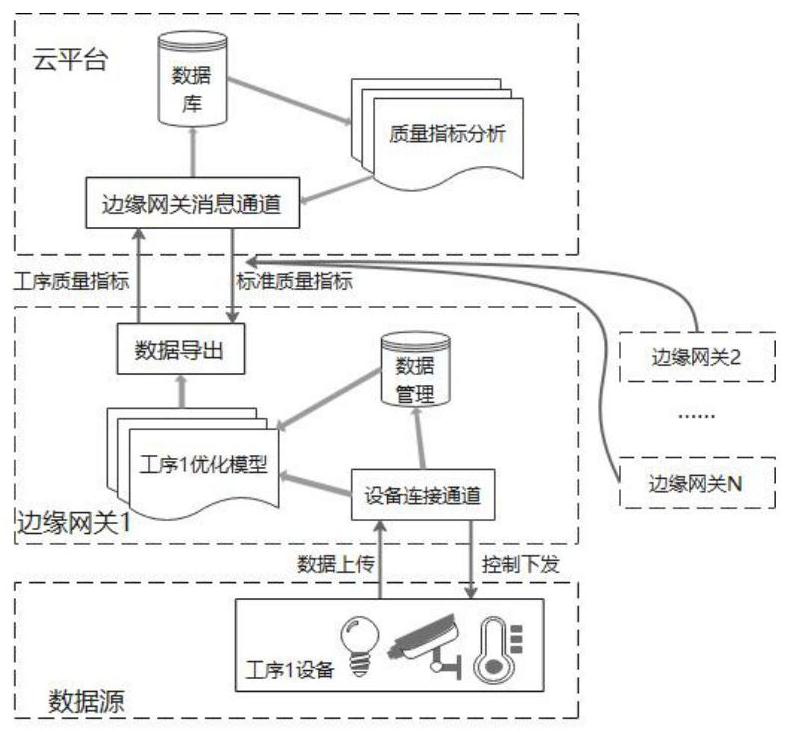

[0026] Embodiment 1: as Figure 1-2 As shown, an edge computing-based tobacco shred process parameter optimization method includes:

[0027] Cloud platform, application server and database server with high computing performance, analyze whether the quality indicators of each process uploaded by the edge layer meet the standards, and return the standard quality indicators to the edge layer;

[0028] The edge layer, composed of multiple edge gateways, receives the process parameters and quality indicators uploaded by the previous process and field layer sensors, uploads the quality indicators to the cloud platform through edge-cloud collaboration, receives the standard quality indicators returned by the cloud platform, and establishes an optimized Model to obtain the optimal process parameters, and at the same time, through side-by-side collaboration, non-standard quality indicators are sent to the edge gateway that manages the next process;

[0029] The field layer is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com