Device and method for measuring deformation of hydrate in supergravity autoclave based on image features

An image feature and measurement device technology, applied in the fields of geological engineering and geotechnical engineering, can solve the problems of blank effective measurement, difficult to accurately measure the surface deformation of hydrate reservoirs, etc., and achieve good working performance, high precision and simple principle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

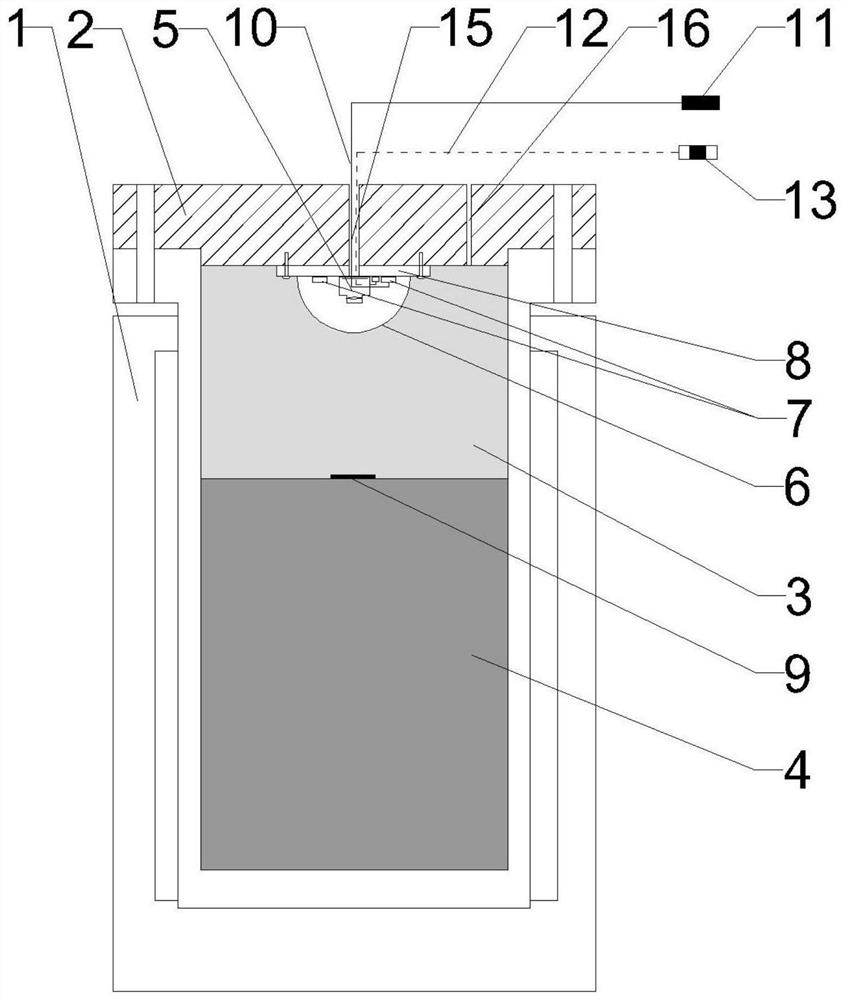

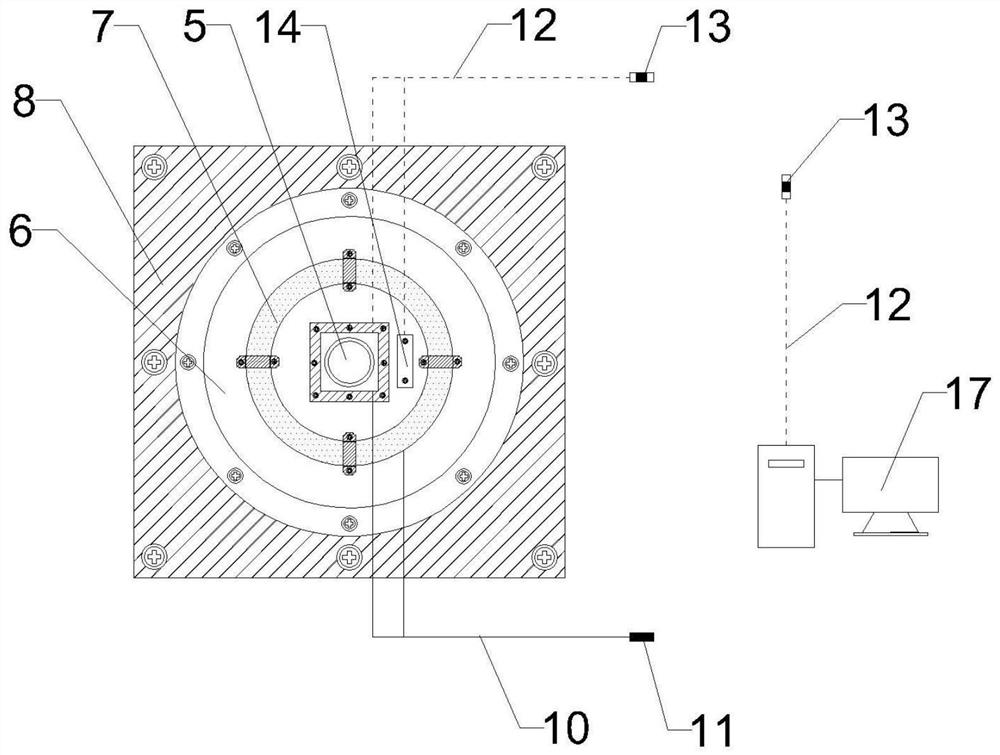

[0072] Such as figure 1 and figure 2 As shown, the device includes an autoclave 1, a kettle cover 2, a high-speed camera 5, a hemispherical tempered glass cover 6, an annular LED lamp tube 7, a base 8, a square metal sheet 9 and an air pressure sensor 14; The cover 2 is placed in a supergravity environment to form a supergravity autoclave; a hydrate simulation reservoir 4 is arranged in the autoclave 1, and high-pressure water 3 is arranged on the hydrate simulation reservoir 4, and the upper surface of the hydrate simulation reservoir 4 is arranged The square metal sheet 9 is arranged between the hydrate simulated reservoir 4 and the interface of the high-pressure water 3, and the bottom surface of the square metal sheet 9 is frosted.

[0073] Base 8 is on kettle cover 2 bottom surfaces, and base 8 is covered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com