Reactive muffler structure capable of adjusting punching rate

A technology of resistance noise reduction and perforation rate, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of poor adaptability, small range, and many transmission links, etc., and achieve simple and reliable structure, High adjustment sensitivity and precision, avoiding the effect of partial load on the end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

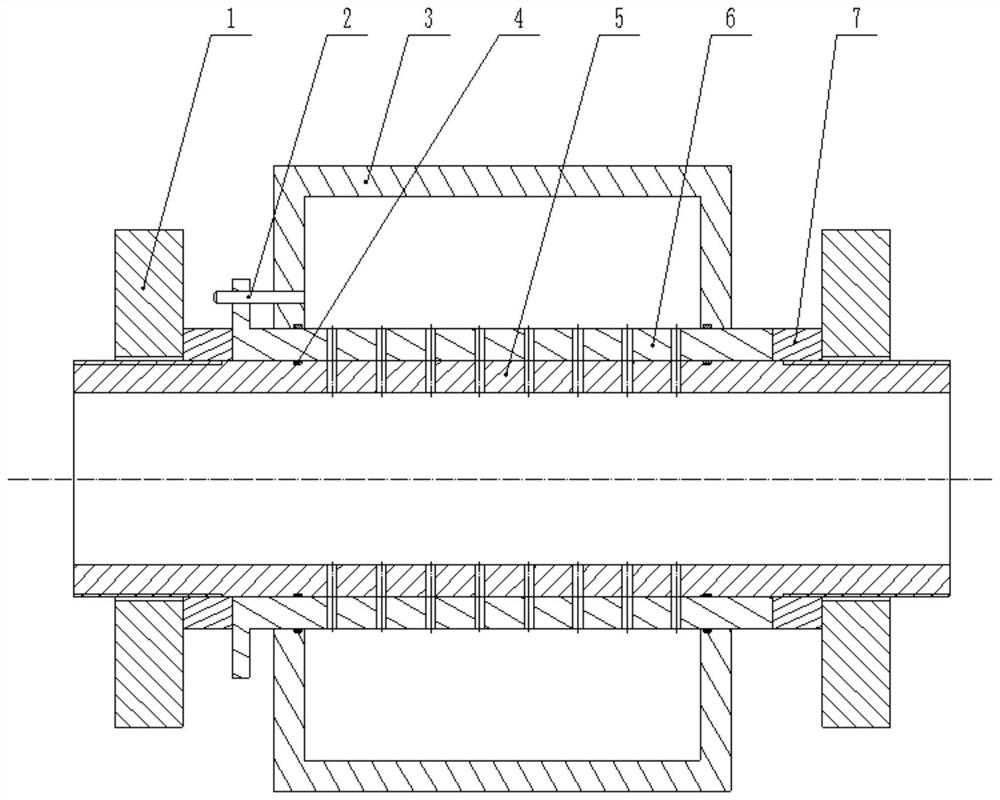

[0016] combined with figure 1 , a resistant muffler structure with an adjustable perforation rate, including an inner perforated cylinder 5 fixedly connected to the pipeline system, an outer perforated cylinder 6 sleeved on the outer surface of the inner perforated cylinder 5, and an outer perforated cylinder 6 A shell 3 is sleeved on the side, and several perforations are evenly opened on the tube wall of the inner perforated cylinder 5 from one end to the other end, and several perforations corresponding to the perforated ones are opened on the outer perforated cylinder 6 Second, the casing 3 is set to cover several perforations 2, the outer surfaces of both ends of the inner perforated cylinder 5 are threaded, and the two ends of the inner perforated cylinder 5 are threaded with nuts 1 .

[0017] The diameters of the first and second holes gradually incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com