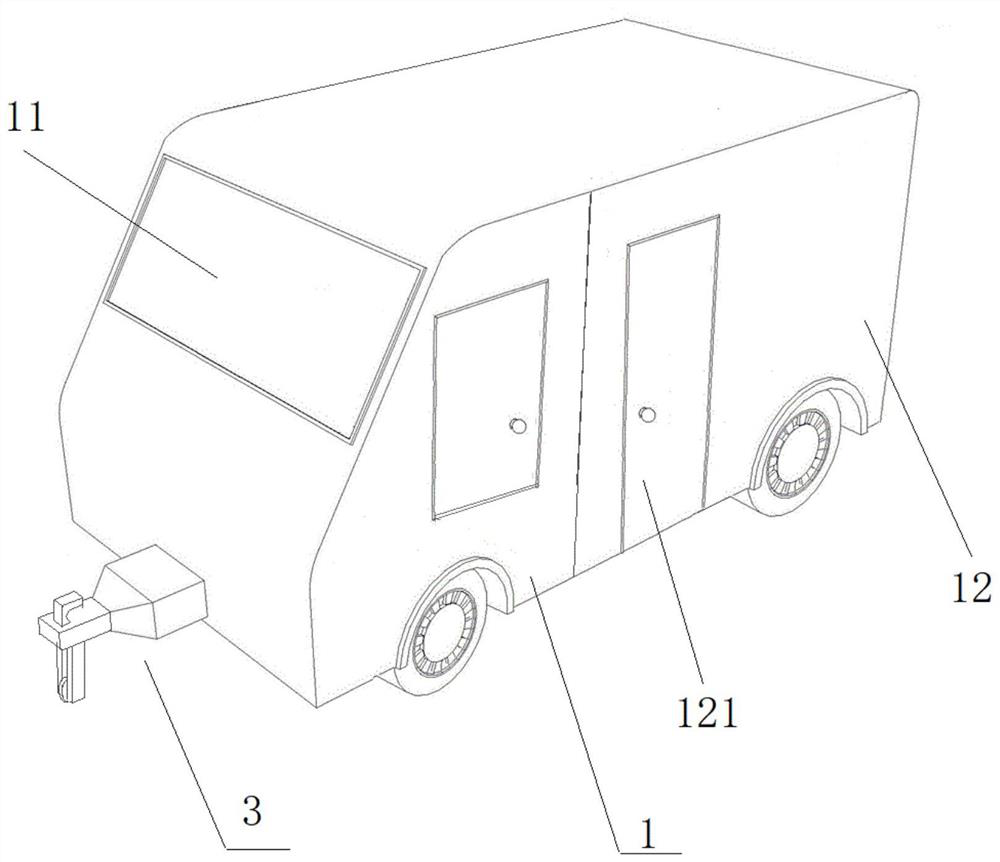

Modular mobile recording studio and working method thereof

A working method and recording studio technology, applied in the field of recording studios, can solve problems such as inconvenient movement and poor flexibility, and achieve perfect sound absorption, reasonable structural design, and satisfying sound insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

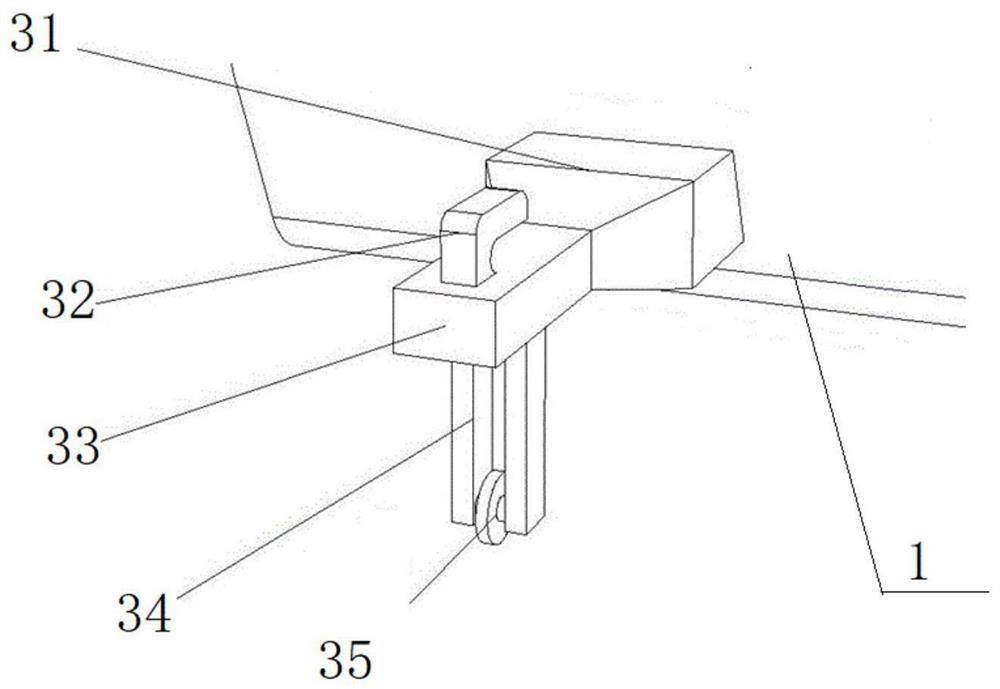

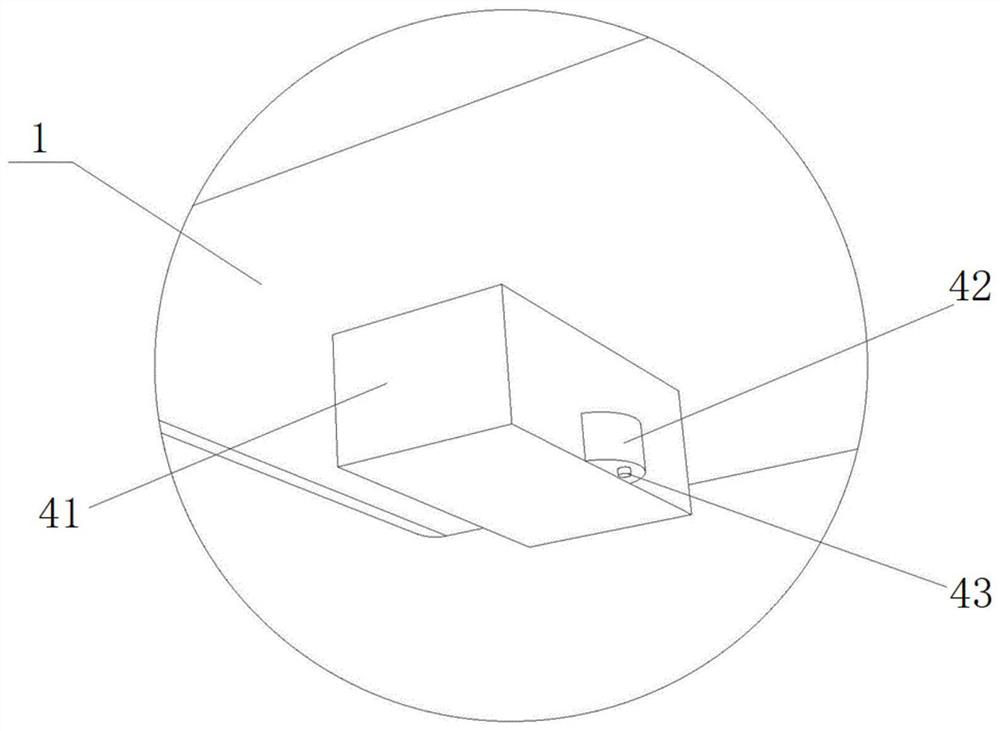

Embodiment 1

[0069] The working method of the modular mobile recording studio of the present invention comprises the following steps:

[0070] 1. Preparation of sound-absorbing material: The first layer of glass wool, the sound-absorbing honeycomb layer, and the second layer of glass wool are stacked and the sound-absorbing material is obtained through an adhesive;

[0071] 2. Decoration of the recording studio: when decorating, the first layer of wooden keel is built on the inner walls of the walls and ceiling of the recording studio 12, and then the above-mentioned sound-absorbing materials are filled, and the second layer of wooden keel is built, and then the overall A fiber semi-perforated decorative panel is installed on the wooden keel, and a sound-absorbing carpet of 15-20mm is laid on the bottom surface of the recording studio room 12; the thickness of the recording room entrance 121 of the recording studio room 12 and the soundproof door 125 of the soundproof wall 124 is 120-150mm;...

Embodiment 2

[0074] The preparation of the material of the sound-absorbing honeycomb layer comprises the following steps:

[0075] 1. The material of the sound-absorbing honeycomb layer mainly includes the following components in parts by mass: 55 parts of bisphenol A epoxy resin, 42 parts of methyl hexahydrophthalic anhydride, 18 parts of hollow polystyrene microspheres, polystyrene 8 parts of ethylene glycol, 1.5 parts of 2-ethyl-4-methylimidazole; bisphenol A type epoxy resin, methyl hexahydrophthalic anhydride, hollow polystyrene microspheres, polyethylene glycol, 2-ethyl - 4-Methylimidazole was put into the rotation / revolution mixer for stirring, first mixed at 1500 rpm for 3 minutes, then degassed at 2000 rpm for 1 min, and repeated 3 times to obtain a mixed solution;

[0076] 2. At room temperature, pour the mixed solution that has been evenly mixed and released from the air bubbles into a stainless steel mold coated with vacuum silicone grease, and then cast into a mold, and then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com