Ultrathin wallboard mounting assembly

A technology for installing components and wall panels, which is applied to floors, covering/lining, buildings, etc. It can solve the problems of ultra-thin wall panels that cannot be grooved, the installation process is cumbersome, and the construction quality is unstable, so as to avoid the exposed joints. , Reduce processing difficulty, prevent edge collapse and warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

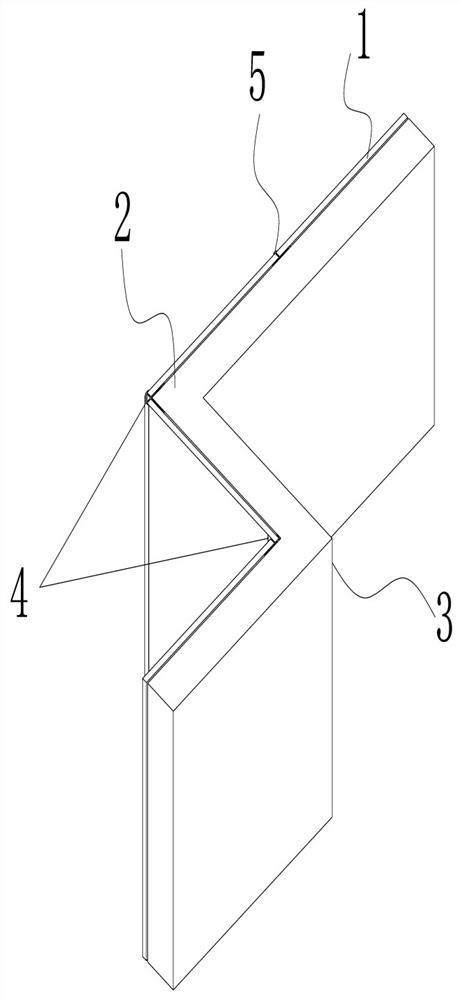

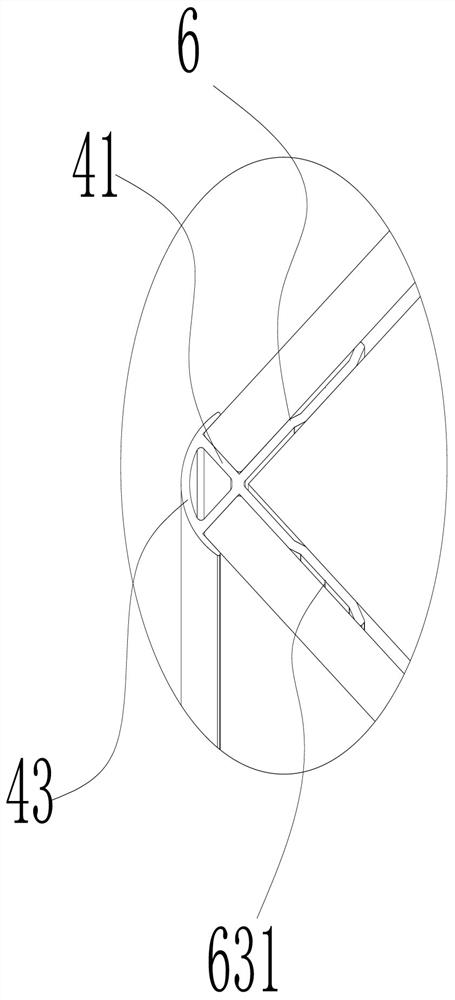

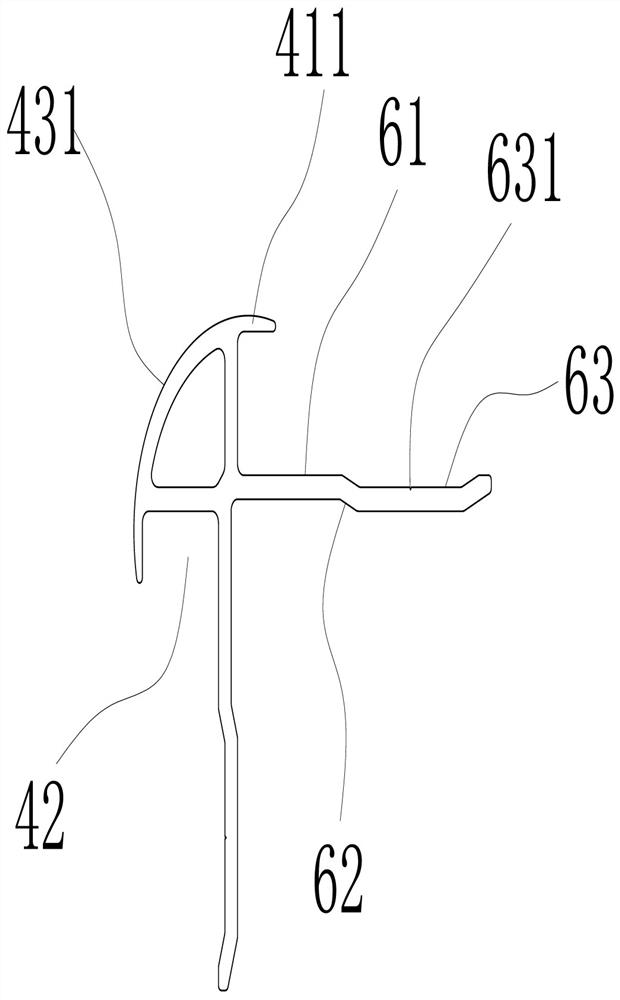

[0030] Embodiment 1: An ultra-thin wall panel installation assembly, such as figure 1 As shown, for the installation between the wall and the wall panel 1, the wall includes two non-parallel connected sub-walls, and a raised first corner 2 or a concave second corner 3 is formed between the two sub-walls. The walls are all equipped with wall panels 1, and the ultra-thin wall panel installation components include wall panels 1 for connecting two parts of the wall, corner pieces 4 installed on the first corner 2 or second corner 3, and used to connect the same Butt joints 5 of two wallboards on the body of wall. Among them, such as image 3 and 7 As shown, the corner piece 4 and the joint piece 5 both include a wall panel connecting portion 61 abutting against the wall panel 1 and a wall connecting portion 63 abutting against the sub-wall body, and the wall panel connecting portion 61 and the wall connecting portion 63 pass through The transition portion 62 is connected so tha...

Embodiment 2

[0038] Embodiment 2: as Figure 4 and 5 The implementation shown is basically the same as implementation 1, with the following differences:

[0039] The corner piece 4 is installed on the second corner 3, and the wall panel connecting portion 61 of the corner piece 4 includes a first abutting end 611 and a second abutting end 612 respectively abutting against the wall panels 1 of the two sub-walls. The connection between the abutting end 611 and the second abutting end 612 is provided with a clamping plate 44 non-parallel to the wallboard connecting portion 61, between the clamping plate 44 and the first abutting end 611, between the clamping plate 44 and the second abutting end Inserting grooves 45 for inserting the wall panels 1 are respectively formed between the connecting ends 612 . The clamping plate 44 includes a supporting end 441 connected to the wallboard connecting portion 61 , and a suspended free end 442 , the free end 442 is provided with an arc-shaped filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com