Fan foundation reinforcing structure and reinforcing method thereof

A technology for wind turbine foundation and reinforcement structure, which is applied in basic structure engineering, repair of foundation structure, assembly of wind turbines, etc., can solve problems such as increased construction cost, weak reinforcement effect, damage to wind turbine foundation, etc., so as to reduce transportation and construction. Cost, uniform distribution of structural loads, and the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

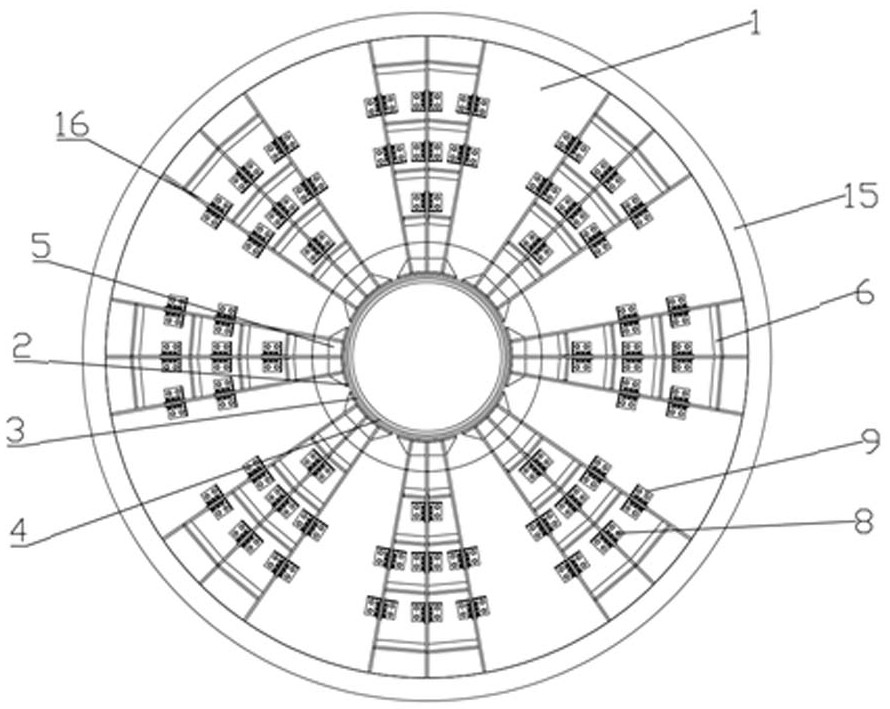

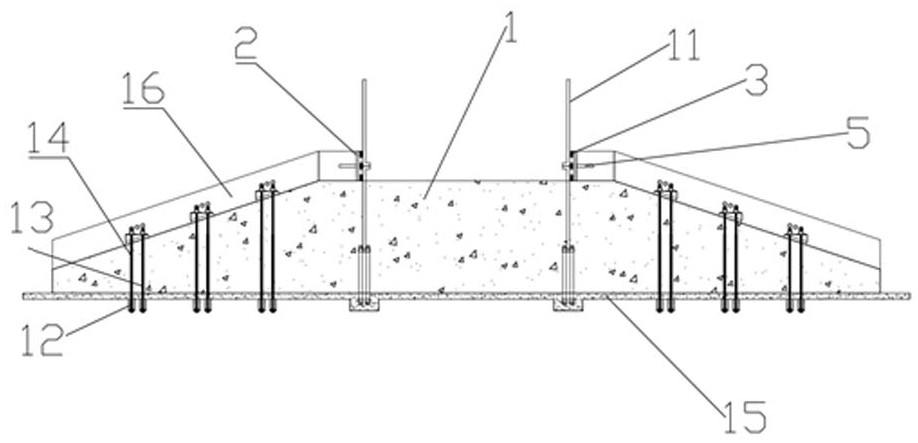

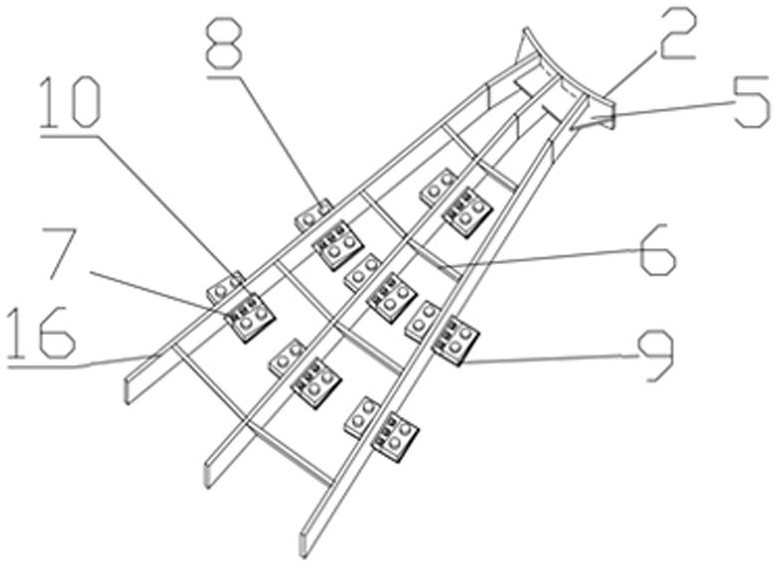

[0023] Such as figure 1 , 2 As shown, the wind turbine foundation reinforcement structure of the present invention has a foundation 1, including a rubber ring 3, a tower 11 and a supporting structure, and the tower 11 relies on the flange at the bottom and the upper flange of the foundation ring 4 inside the foundation 1 The discs are connected to each other by high-strength bolts; the rubber ring 3 is set on the tower tube 11, and the inner wall of the rubber ring 3 is fixed on the outer wall of the tower tube 11 through glue connection, and the curved arc of the arc supporting steel plate 2 and the rubber ring 3 Consistent, the two fit each other; if image 3 As shown, the supporting structure is composed of the arc supporting steel plate 2 supporting the tower tube 11, the vertical supporting steel plate 16 supporting the arc supporting steel plate 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com