Severe plastic deformation process for powder substances

A technology of severe plasticity and substance, applied in the field of powder materials, can solve the problems of low preparation density and low tensile strength, achieve good heating effect, high tensile strength, and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

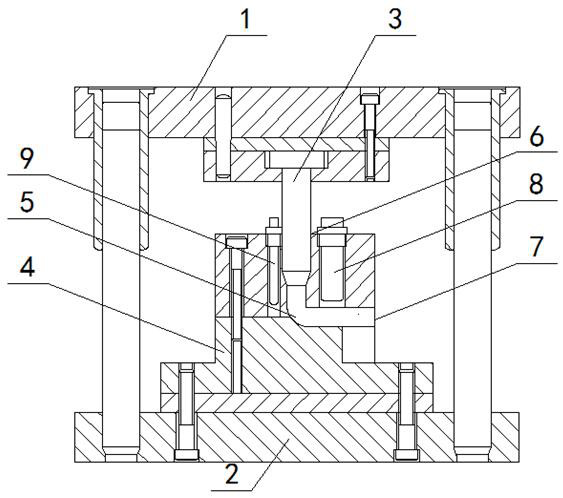

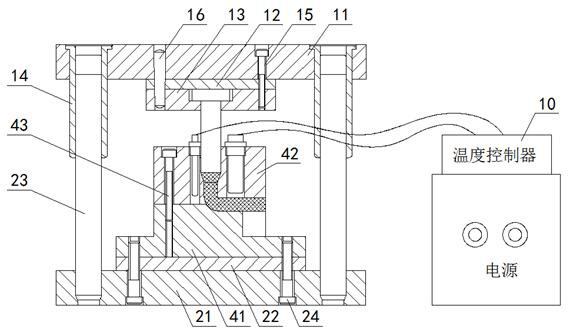

[0054] see Figure 1 to Figure 8 , a severe plastic deformation process for a powdery substance, the severe plastic deformation process comprises the following steps:

[0055] Feeding steps of the powder material: firstly seal the discharge port 7 of the lower mold 2, and then inject the powder material from the feed port 6 of the lower mold 2 into the cavity 5 of the die, and the powder material is located in the cavity of the die In the channel 5; the compaction steps of the powder material: firstly, the upper mold 1 is moved vertically downward to drive the punch 3 on the upper mold 1 to move downward together, and then the lower punch 3 pairs the concave The powder material in the die channel 5 is extruded. During the pressing process of the punch 3, the powder material continues to be under the pressure exerted by the punch 3, and the pressed powder material moves down along the die channel 5, During the downward movement of the powdery material, the powdery material is ...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

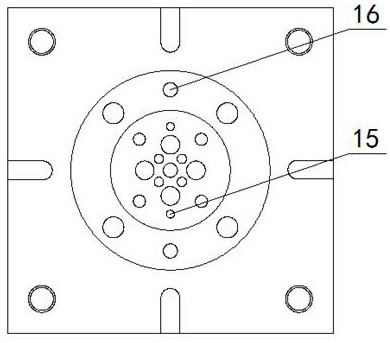

[0059] see Figure 1 to Figure 8 , the bottom surface of the lower mold 2 and the top surface of the upper mold 1 are planar structures, the upper mold 1 is connected with the slide block of the press, the lower mold 2 is connected with the workbench of the press, and the upper mold 1 The bottom of the bottom is provided with a punch 3, the top of the lower mold 2 is provided with a die 4, the die 4 is provided with a die channel 5, and the top of the die 4 is provided with a feed port 6, the One side of the die 4 is provided with a discharge port 7, and the feed port 6 communicates with the discharge port 7 through the die passage 5; the die passage 5 includes a first vertical cavity 51, a second vertical cavity 52 , the third vertical cavity 53, the curved cavity 54 and the horizontal cavity 55, the first vertical cavity 51, the second vertical cavity 52, and the third vertical cavity 53 are connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com