Method for configuring weighted drilling fluid

A technology of weighted drilling fluid and fluid flow, applied in the direction of mixing methods, drilling compositions, chemical instruments and methods, etc., can solve the problems of long preparation and circulation time, poor initial performance of weighted drilling fluid, etc.

Inactive Publication Date: 2008-11-26

WESTERN DRILLING KELAMAYI DRILLING TECH INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

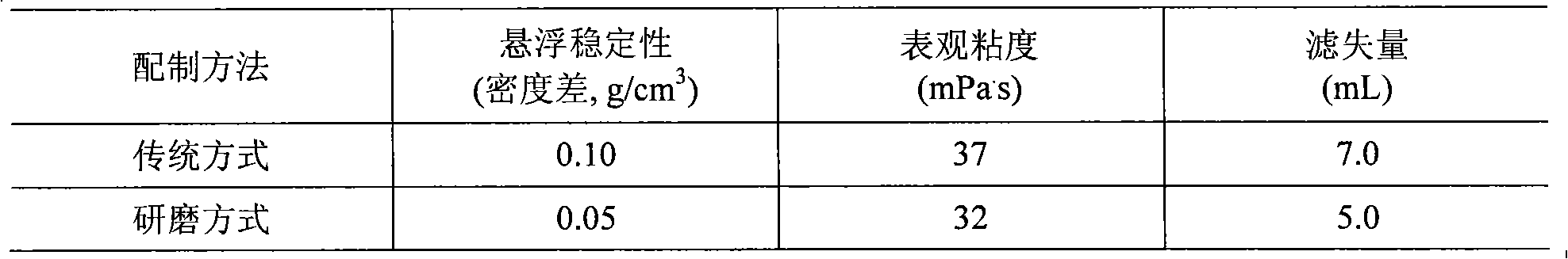

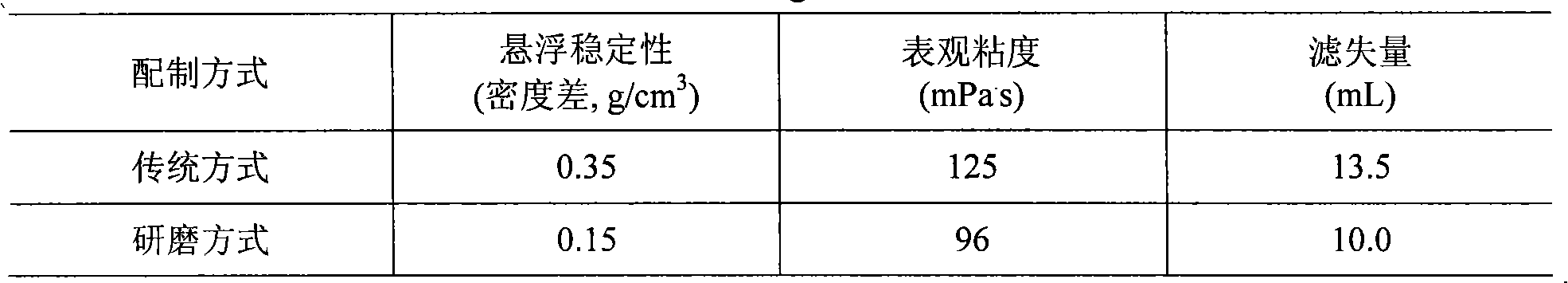

Due to the large amount of solid substances added in the weighted drilling fluid, it takes a process for the solid substances to dissolve, wet and disperse in the liquid to form a stable suspension. The traditional preparation method mentioned above has a long preparation and cycle time, and the second is to prepare The initial performance of the heavy drilling fluid is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method of weighted drilling fluid, wherein, a plurality of pieces of milling equipment are added during the preparation of the weighted drilling fluid on the basis of the conventional processes of stirring and mixing as well as liquid flow shearing, and the series connection, parallel connection or the combination of both is adopted, namely to add a milling procedure. Furthermore, a milling method and the conventional stirring and mixing method, or the milling method and the conventional liquid flow shearing method, are mutually combined to prepare the weighted drilling fluid. The milling equipment comprises any machine product that is provided with the structure of flexible and static cutting discs or a stator and a rotor and generates the milling function by relative motion, such as a colloid mill, an asphalt colloid mill, a food paste mill, etc. By adopting the milling method, the weighted drilling fluid prepared can be not only applied to the laboratory evaluation, but also applied to the factory-like production or the on-site petroleum drilling; the maximum density of the prepared drilling fluid can be up to 3.0 g / cm<3>.

Description

technical field The invention belongs to the field of petroleum drilling, and in particular relates to a method for preparing heavy drilling fluid by grinding. Background technique Drilling fluid is a circulating fluid used in oil drilling. It is a colloidal suspension prepared by adding solid substances to liquid (water or oil). The traditional method of preparing drilling fluid is to add solid substances into the liquid by stirring and mixing (mixer) and liquid flow shearing (nozzle, spray gun), and then repeatedly stir and shear in the circulation process until a stable suspension is formed. body. Due to the large amount of solid substances added in the weighted drilling fluid, it takes a process for the solid substances to dissolve, wet and disperse in the liquid to form a stable suspension. The traditional preparation method mentioned above has a long preparation and cycle time, and the second is to prepare The initial performance of the weighted drilling fluid is poo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01F13/10B01F3/12C09K8/00

Inventor 马世昌杨玉良黄治中

Owner WESTERN DRILLING KELAMAYI DRILLING TECH INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com