Variable-rigidity swing joint and rigidity control method thereof

A technology of stiffness and joints, which is applied in the field of variable stiffness swing joints and their stiffness control, can solve problems such as difficulty in effective control of stiffness, complex structure of flexible joints, etc., achieve great application value, simple and practical mechanical structure, and avoid sealing problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

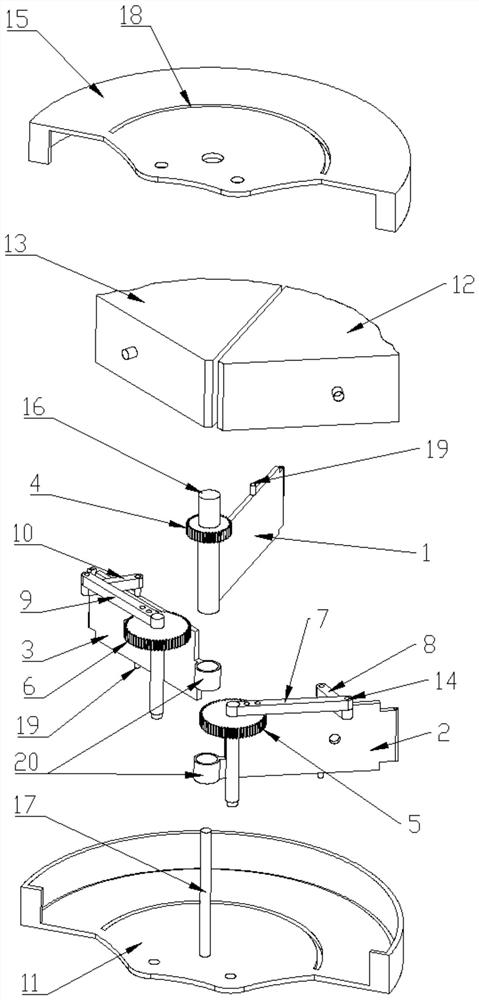

[0026] Example: A variable stiffness swing joint, such as Figure 1-5 As shown, it includes a fixed frame 11, a cover plate 15 and a swing shaft 16, wherein the cover plate 15 covers the fixed frame 11 to form a fan-shaped joint structure. The fixed frame 11 is provided with a shaft center 17, and the swing shaft 16 is rotatably sleeved. Set on the shaft center 17, one side of the swing shaft 16 is fixedly connected with the swing plate 1, the two sides of the swing plate 1 are respectively provided with the left side plate 3 and the right side plate 2, and the ends of the left side plate 3 and the right side plate 2 Shaft sleeves 20 are respectively provided in dislocation, and the shaft sleeves 20 of the left side plate 3 and the right side plate 2 are sleeved on the shaft center 17 respectively, and are located below the swing shaft 16, so that the swing plate 1, the left side plate 3 and the right side plate 2 can rotate around the same axis 17.

[0027] In the above stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com