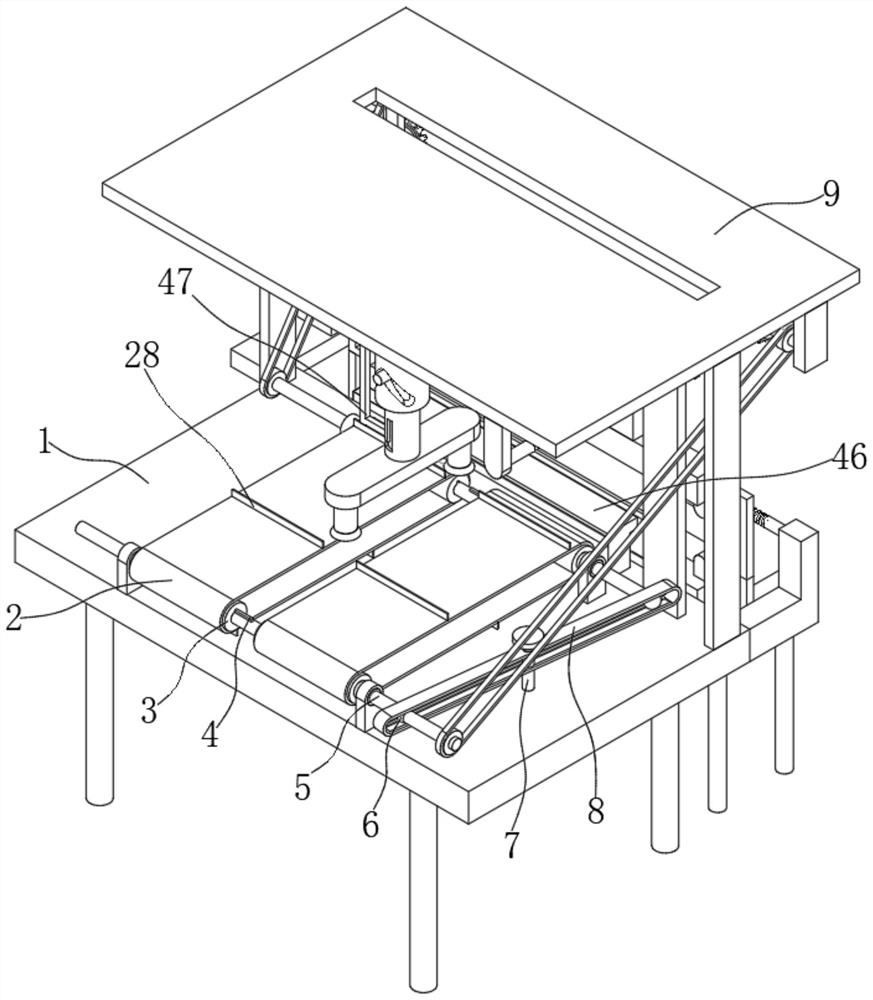

A CNC automatic shearing machine for metal processing

A metal processing and numerical control technology, which is applied to metal processing equipment, manufacturing tools, shearing devices, etc., can solve the problems of affecting the shearing effect of metal plates and uneven incisions of metal plates, so as to improve the shearing effect and apply sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

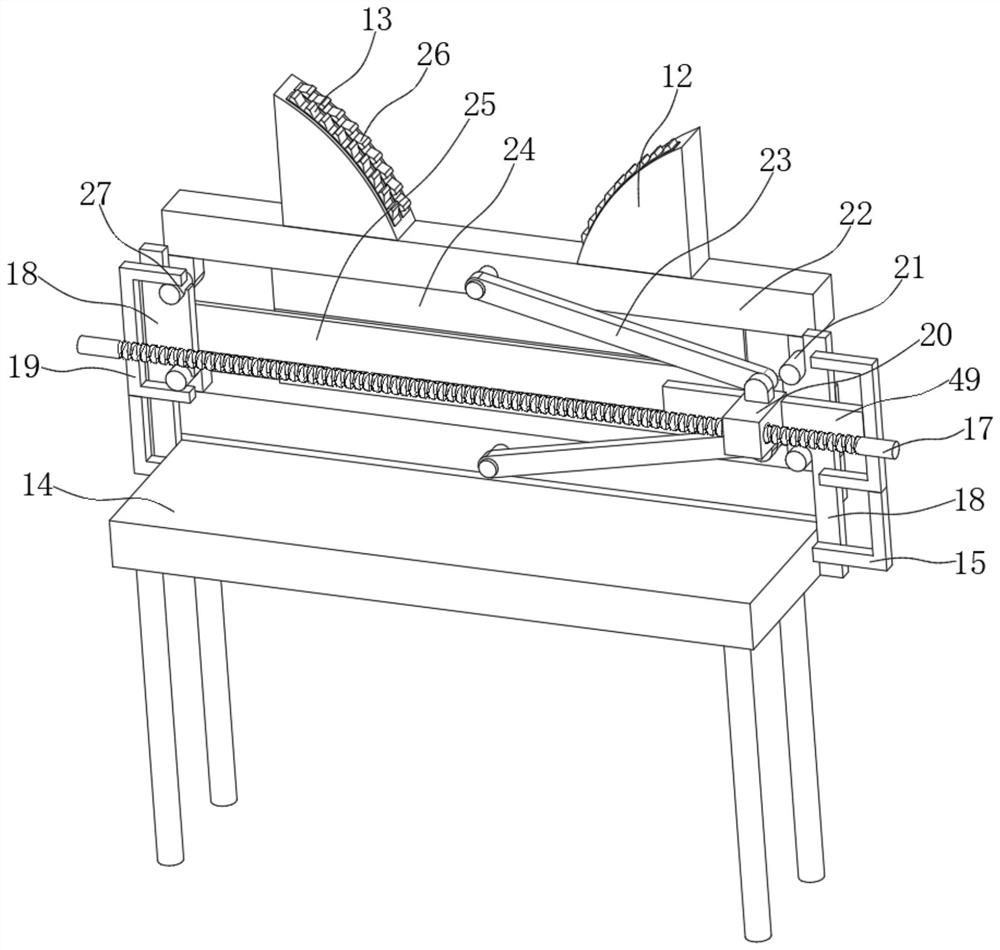

[0034] A drive mechanism for driving the two cutter plates 22 to rotate is also included.

[0035] The cutter plate 22 is driven to rotate by the drive mechanism, because the two end portions of one of the limiting frames 19 connect the two cutter plates

[0036] The two mounting bases 18 are jointly fixed with a shearing knife 24 near the outer wall of the cutter plate 22, and the shearing knife 24 is close to the cutter plate

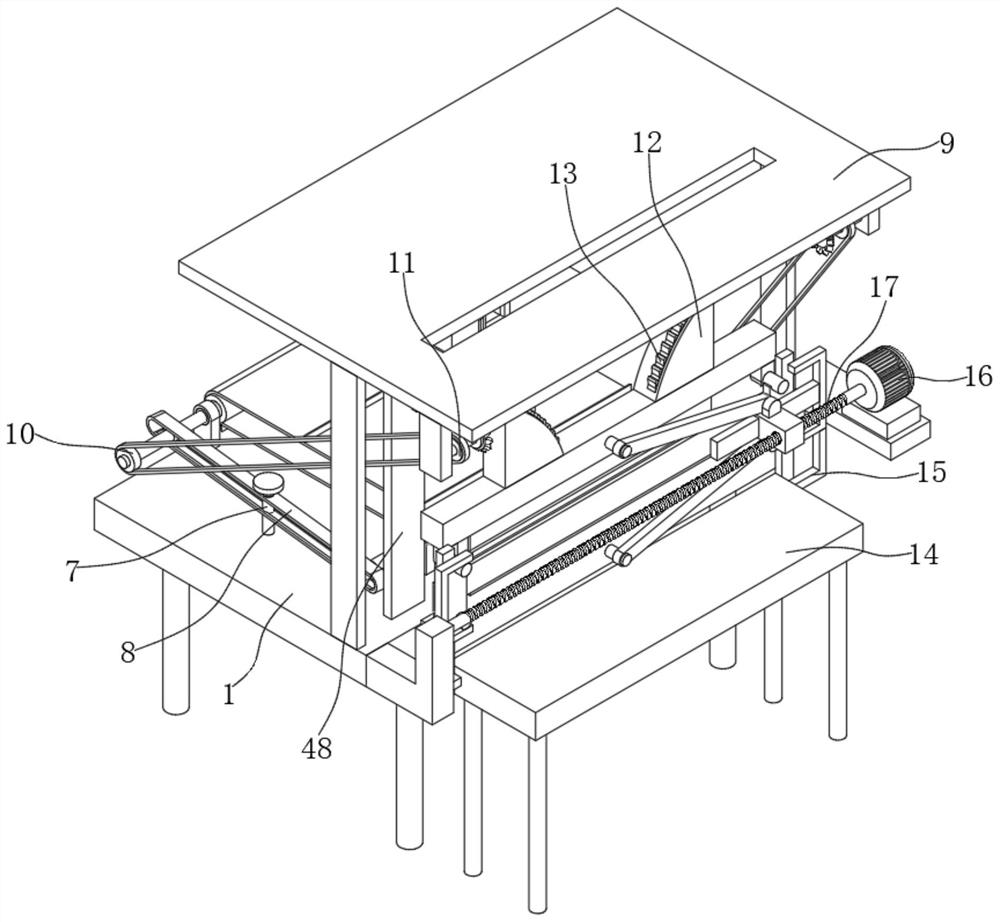

[0043] The top of the upper tool plate 22 near both sides is fixed with the arc plate 12, and the axes of the two arc plates 12 are

[0050] Also includes a reciprocating mechanism for driving the rotating drum 30 to reciprocate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com