Method for forming complex double-curvature skin part

A technology of skin parts and double curvature, which is applied in the forming field of complex double curvature skin parts, to achieve good surface quality of parts, suppress wrinkling, and eliminate uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

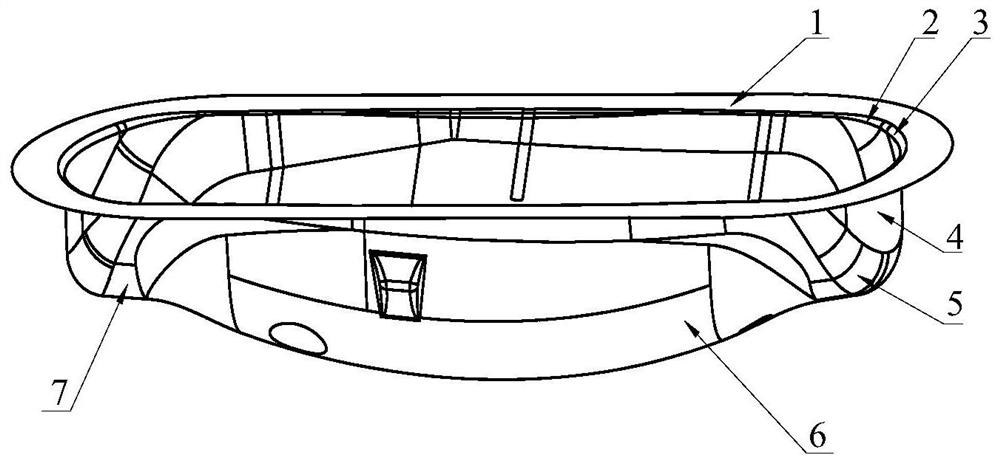

[0024] figure 1 -5 is a schematic diagram of the liquid-filled forming process of a large complex hyperbolic skin part of the present invention, and the forming process mainly includes the following steps:

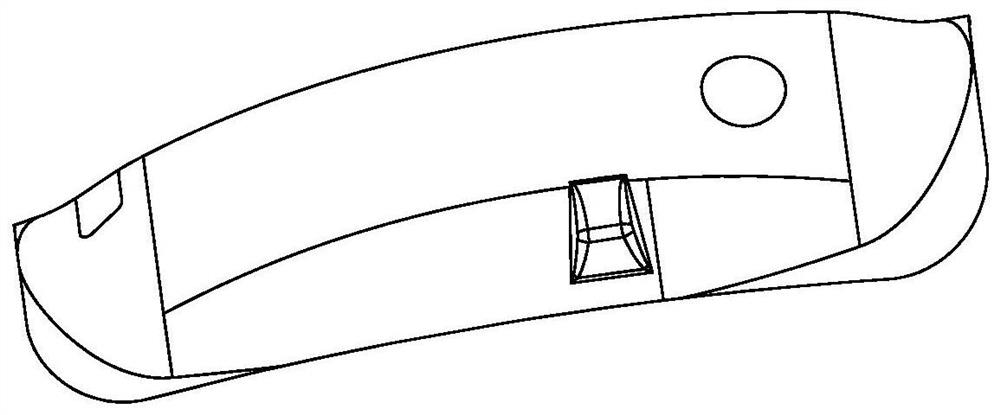

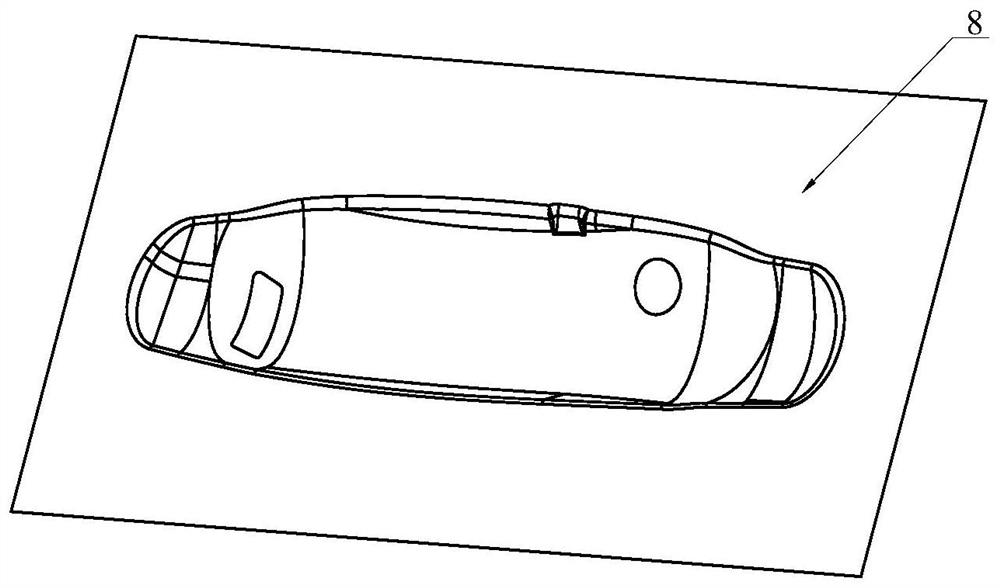

[0025] 1 Construction reference surface: adjust the drawing direction according to the hyperbolic skin part model 6, so that the final drawing height of the part can be minimized, construct the normal plane of the drawing direction, and the normal plane is in the range of 15mm-25mm above the part model Inside, the drawing contour line 2 and the flange surface 1 are constructed on the normal plane, and the two ends of the drawing contour line 2 adopt a large arc for transition. The drawing contour line 2 is larger than the part model 6 contour, and the drawing contour line 2 Construct the drawing surface 4 along the drawing direction, intersect the extrapolated extension surface 7 of the part model 6 with the drawing surface 4, and intersect the flange surface 2 with the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com