A high-end equipment surface coating application equipment

A technology of surface coating and equipment, applied in the field of smearing equipment, can solve the problems of uneven smearing and soiling of clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

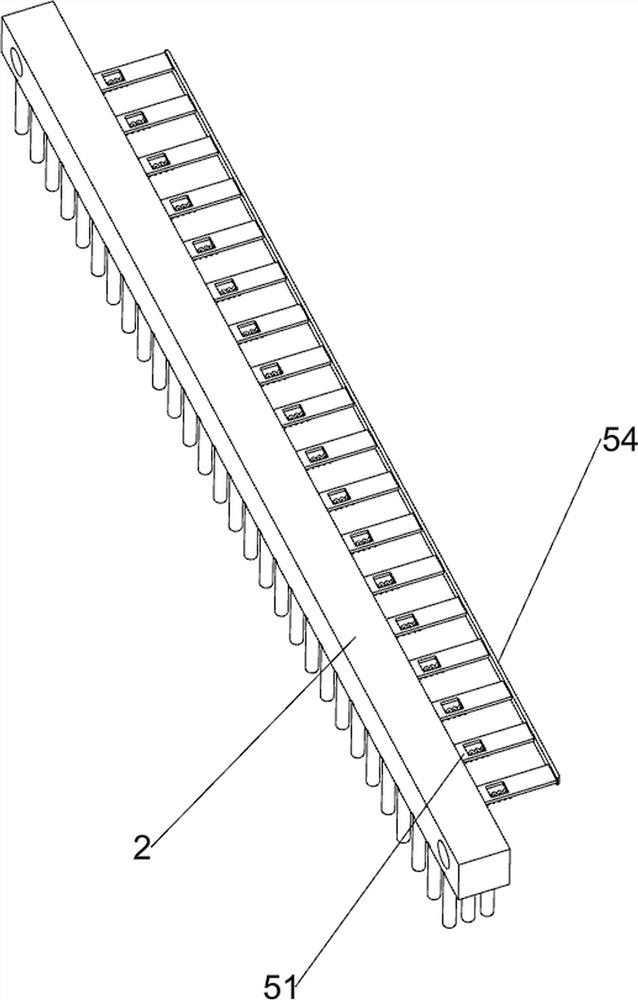

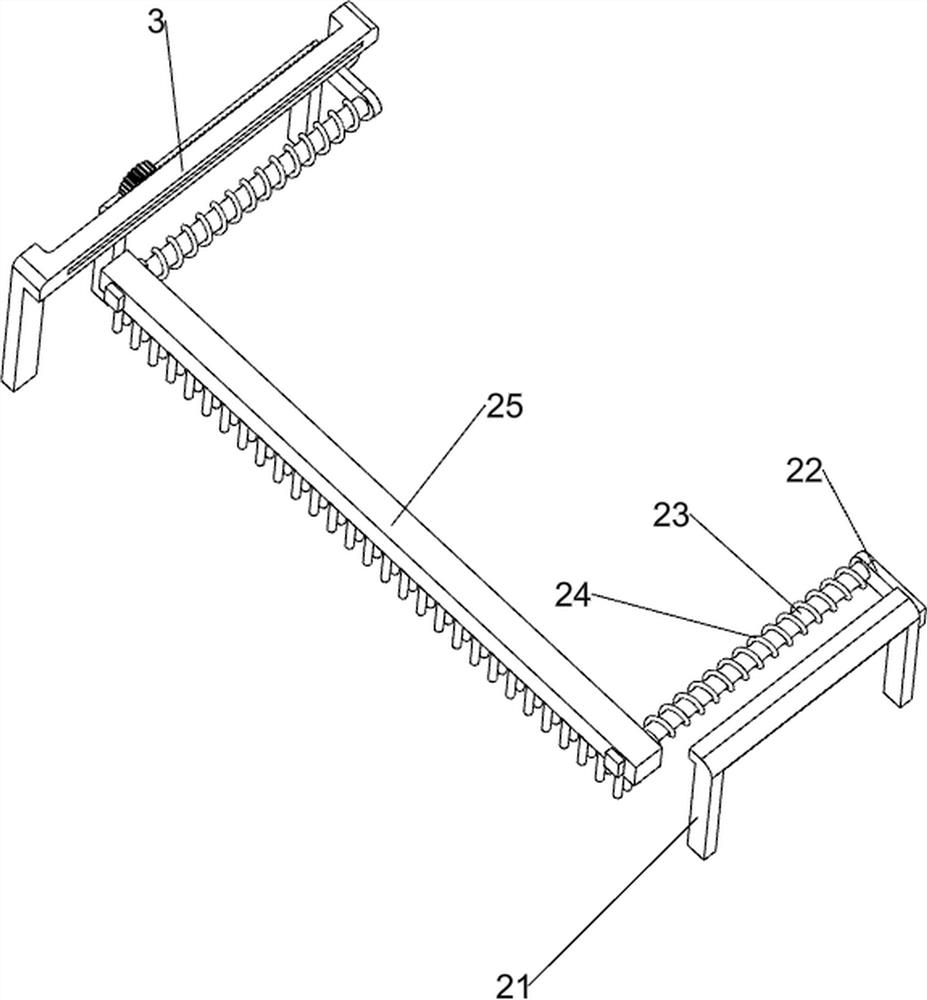

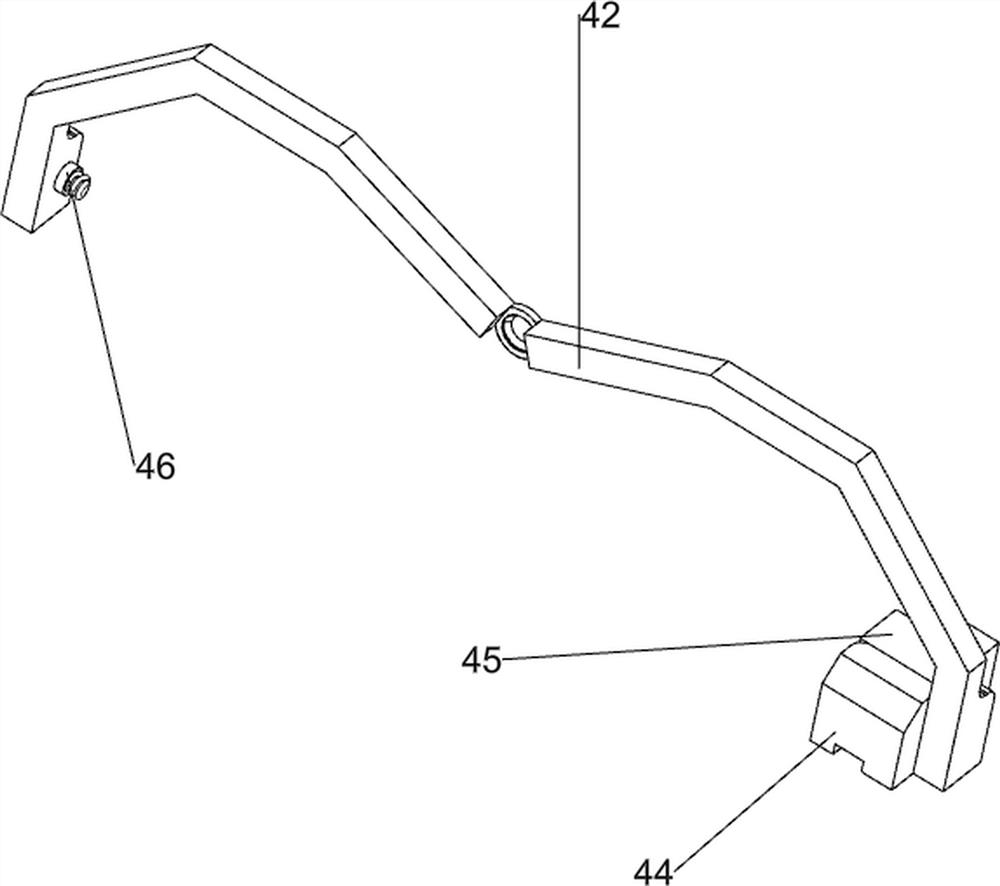

[0027] A high-end equipment surface coating application equipment, such as Figure 1-9 As shown, it includes a base 1 , a coating mechanism 2 and a feeding mechanism 3 , a coating mechanism 2 is provided in the middle of the base 1 , and a feeding mechanism 3 is provided on the rear side of the coating mechanism 2 .

[0028] When people need to apply coating on the surface of high-end equipment, they put the paint into the unloading mechanism 3, move the high-end equipment to the lower part of the coating mechanism 2 and the unloading mechanism 3, and the paint flows down from the unloading mechanism 3 to the top of the high-end equipment. When the paint continues to move, the application mechanism 2 applies the paint on the high-end equipment.

[0029] The smearing mechanism 2 includes a bracket 21, a mounting seat 22, a guide rod 23, a first spring 24 and a brush 25; A guide rod 23 is provided between the front sides of the seat 22 , a brush 25 is slidably provided between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com