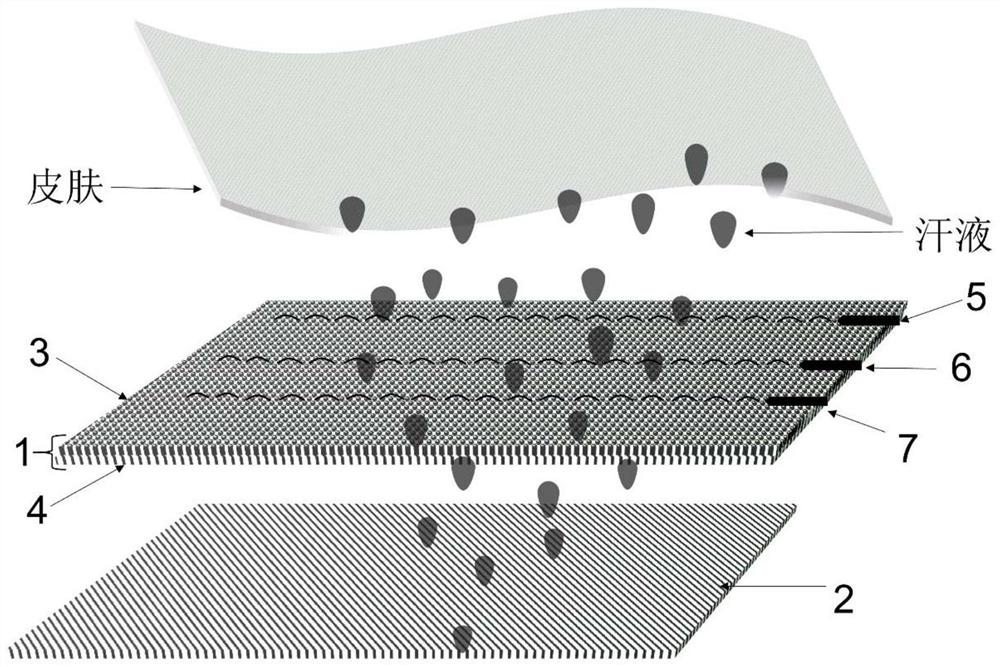

One-way flow guide fabric-based wearable sweat sensor and preparation method thereof

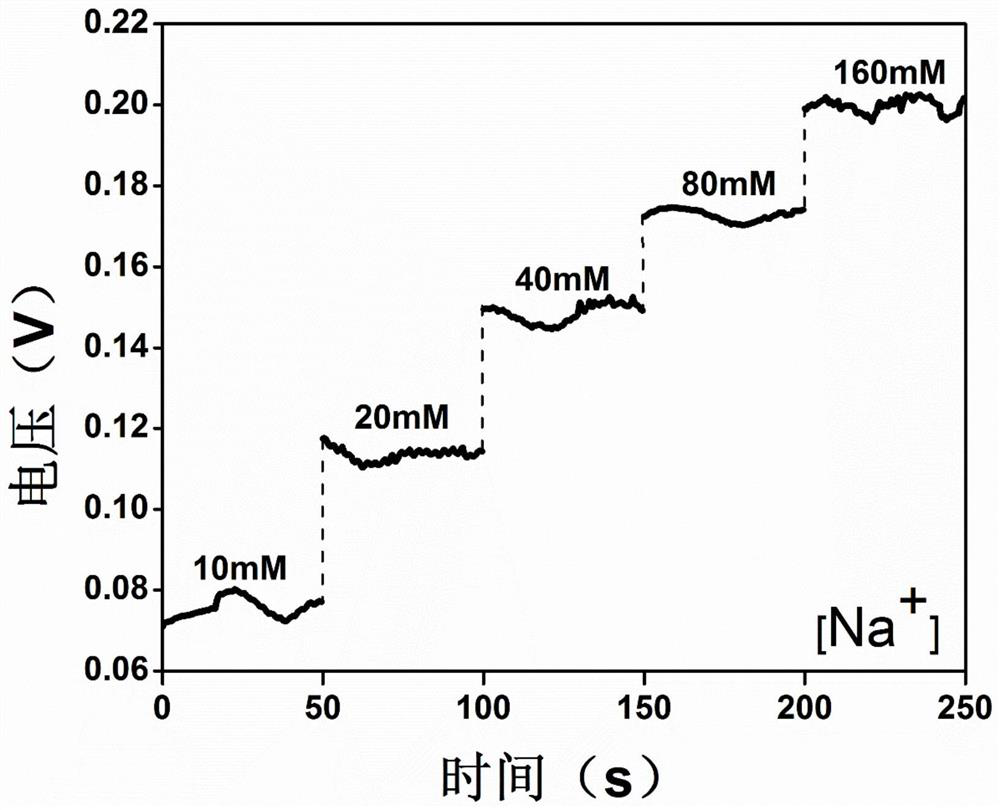

A unidirectional flow and sensor technology, applied in sensors, blood characterization devices, medical science, etc., can solve the problems of poor flexibility, poor wearable comfort, inaccurate detection, etc., and achieve low cost and wide range of physiological substance monitoring concentration , the effect of high signal sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of a unidirectional flow fabric-based wearable sweat sensor, the specific steps are as follows:

[0054] (1) prepare sweat unidirectional flow-conducting layer;

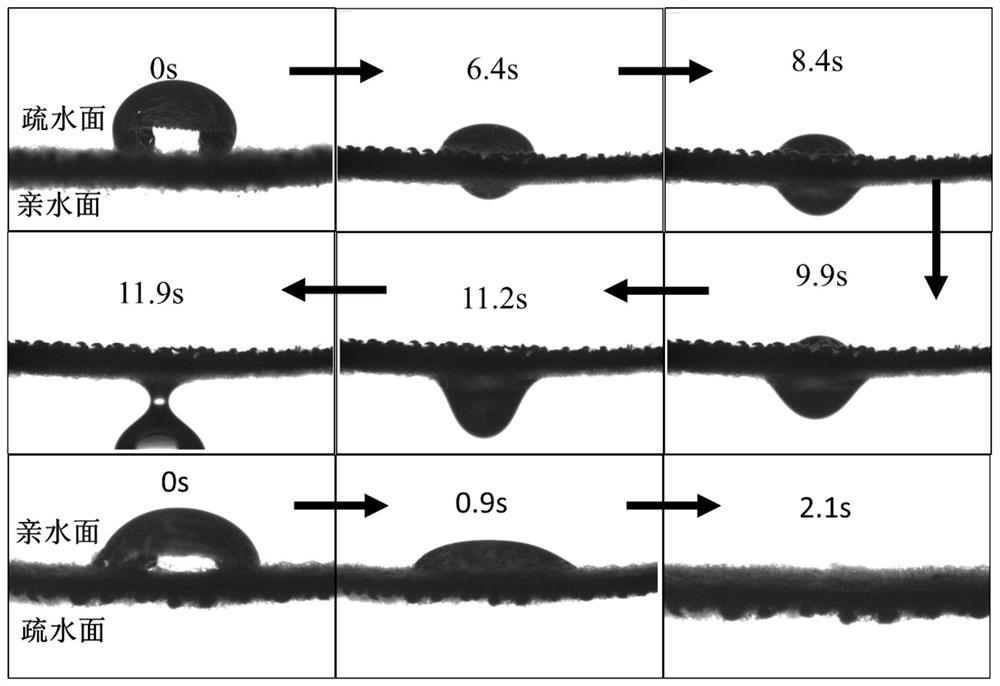

[0055] At constant spray gun pressure 1kgf / cm 2 Keep the spray gun mouth and the cotton fabric at a vertical distance of 30cm, spray the hydrophobic agent evenly on one side of the fabric, control the spraying amount of the hydrophobic agent to 20mg, preheat and bake at 100°C for 80min; cm 2 Keep the vertical distance of 20cm between the nozzle of the spray gun and the fabric, spray the hydrophilic agent evenly on the other side of the fabric, control the spraying amount of the hydrophilic agent to 100mg, and then place it under the UV light curing instrument for photocatalysis for 40min to obtain sweat single guiding layer;

[0056] The hydrophobic agent is a mixed solution of water-based polyurethane (modified polyurethane emulsion, refer to Chinese patent 201910998628.8 for the prepa...

Embodiment 2

[0086] A preparation method of a unidirectional flow fabric-based wearable sweat sensor, the specific steps are as follows:

[0087] (1) prepare sweat unidirectional flow-conducting layer;

[0088] At constant spray gun pressure 2kgf / cm 2 In the next step, keep a vertical distance of 40cm between the nozzle of the spray gun and the polyester-cotton blended fabric with a mass ratio of 1:1, spray the hydrophobic agent evenly on one side of the fabric, control the spraying amount of the hydrophobic agent to 40mg, and bake it at 115°C after preheating 65min; at constant spray gun pressure 2kgf / cm 2 Keep the vertical distance of 30cm between the nozzle of the spray gun and the fabric, spray the hydrophilic agent evenly on the other side of the fabric, control the spraying amount of the hydrophilic agent to 130mg, and then place it under the UV light curing instrument for photocatalysis for 60min, and then the sweat single guiding layer;

[0089] The hydrophobic agent is a mixed ...

Embodiment 3

[0098] A method for a unidirectional flow-through fabric-based wearable sweat sensor, the specific steps are as follows:

[0099] (1) prepare sweat unidirectional flow-conducting layer;

[0100] At constant spray gun pressure 4kgf / cm 2 Keep the nozzle of the spray gun at a vertical distance of 50cm from the polyester fabric, spray the hydrophobic agent evenly on one side of the fabric, control the spraying amount of the hydrophobic agent to 60mg, preheat and bake at 130°C for 50min; cm 2 Keep the vertical distance of 45cm between the nozzle of the spray gun and the fabric, spray the hydrophilic agent evenly on the other side of the fabric, control the spraying amount of the hydrophilic agent to 160mg, and then place it under the UV light curing instrument for photocatalysis for 70min to obtain sweat single guiding layer;

[0101] The hydrophobic agent is a mixed solution of water-based polyurethane (modified polyurethane emulsion, refer to Chinese patent 201910998628.8 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com