Two-section type composite shoe tree and preparation method thereof

The technology of shoe last and clamping piece is applied in the field of two-section composite shoe last and its preparation, which can solve the problems of uneven size and variation of the cutting surface, and achieve the effects of low utilization cost, complete cutting surface and saving processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

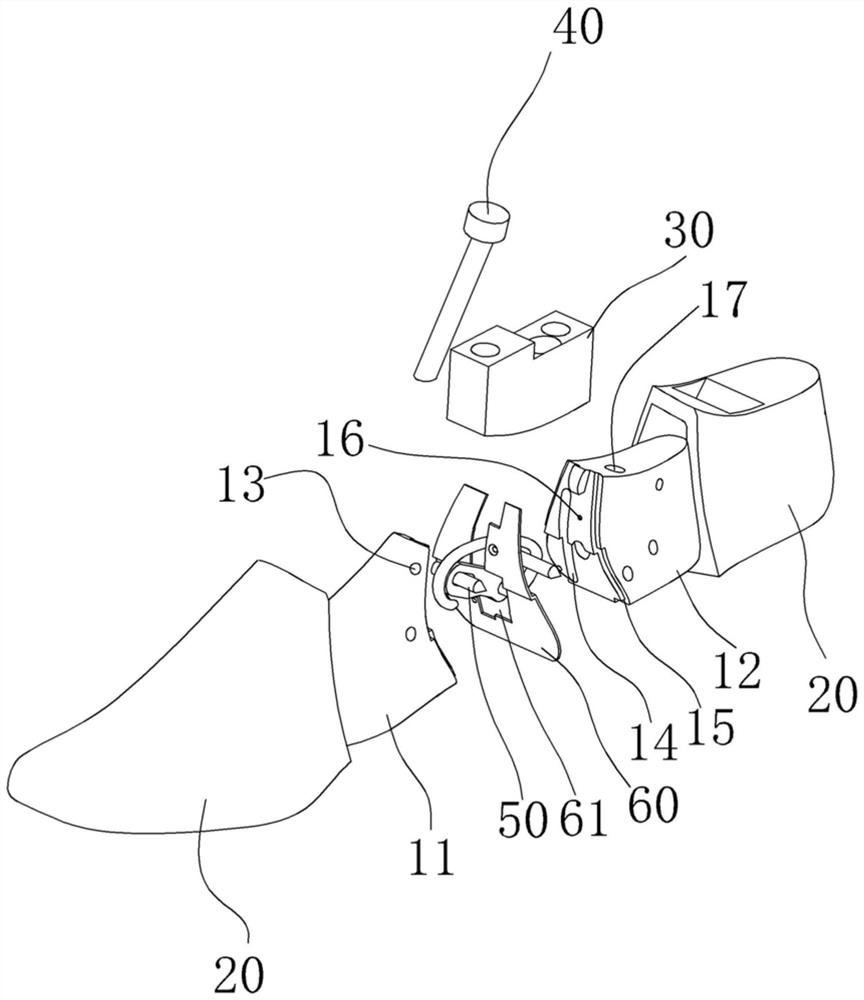

Image

Examples

preparation example Construction

[0034] In order to obtain the above-mentioned two-section composite shoe last, the technical solution adopted by the present invention is a preparation method of a two-section composite shoe last, which includes the following steps:

[0035] Preparation of the last core: heat and melt aluminum or aluminum alloy into molten aluminum, then pour the molten aluminum into the inner core mold of the die-casting machine, and release the molten aluminum after the mold solidifies through water cooling mode to obtain the first core and the second last core;

[0036] Assembly: sandwich the separator between the first core and the second core, and assemble the first core and the second core through the connecting component to obtain the aluminum core;

[0037] Injection molding: add plastic material to the injection molding machine for heating and dissolving, put the aluminum last core into the mold of the injection molding machine for injection molding wrapping;

[0038] Cooling and sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com