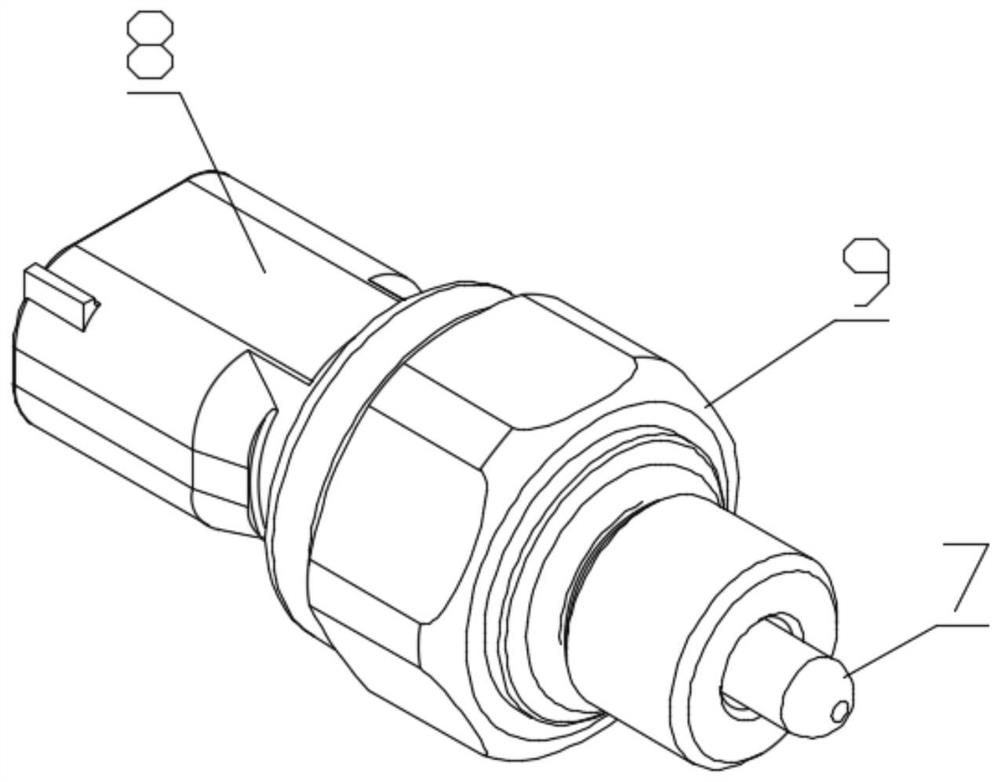

Pressure and temperature sensor for oil

A pressure temperature and sensor technology, applied in the field of sensors, can solve the problems of hidden damage of electronic components, high assembly process requirements, and close proximity of electronic components, so as to avoid hidden damage, improve market competitiveness, and reduce high-temperature processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

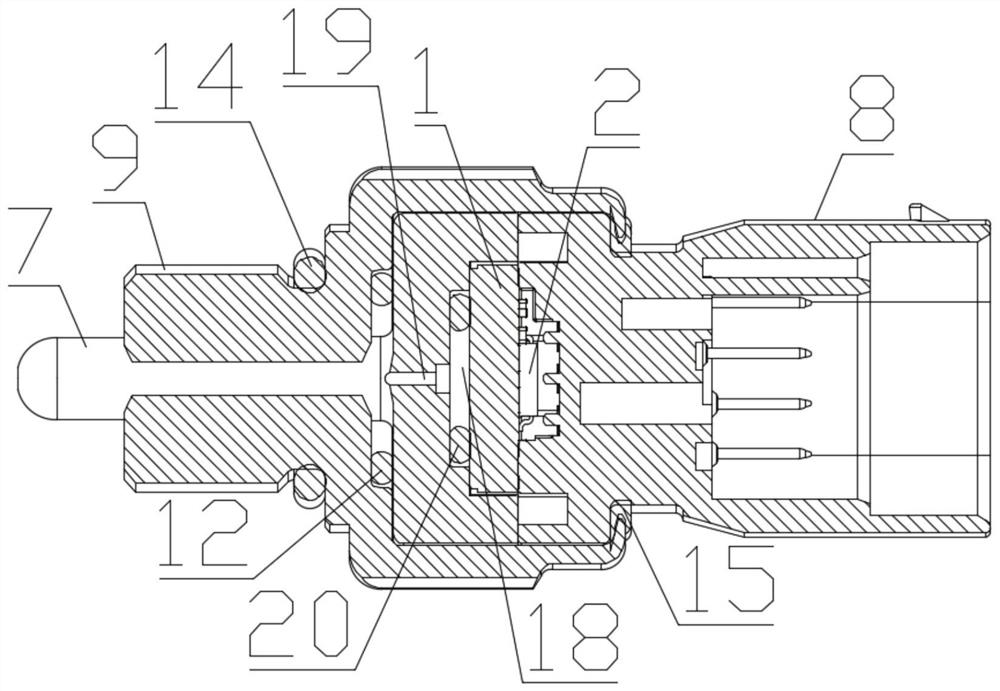

[0037] Such as Figure 4 and 6 As shown, as an optimization of the NTC base 7 in a pressure temperature sensor for oil in the present invention, the NTC base 7 is T-shaped, and the head end of the NTC base 7 is built with The thermistor 6, the end of the NTC base 7 is provided with an installation groove 16 that can be installed with the pressure module 1, and the body of the NTC base 7 is built with the lower pin 5; The outer wall of the groove 16 is provided with a spring installation hole 17 for the end part of the lower pin 5 to penetrate, and the spring 4 is partially embedded in the spring installation hole 17, and the other end of the spring 4 is connected to a part of the The upper stitches 3 are connected so that the upper stitches 3 and the lower stitches 5 form an elastic connection. Wherein, the upper pin 3 is connected to the ceramic pressure module 1 through the S-shaped spring piece 13 welded on the welding pad of the ceramic pressure module 1 to form an elast...

Embodiment 2

[0044] Such as Figure 4As shown, it is an optimization of the oil pressure detection channel in a pressure temperature sensor used for oil according to the present invention. Along the bottom side of the installation groove 16, there is an oil pressure chamber groove 18, and the oil pressure chamber groove 18 can be in conflict with the bottom side of the ceramic pressure module 1 to form a closed space for storing oil; At least one through hole 19 through which oil can pass is opened on the bottom side of the oil pressure cavity 18 .

[0045] Preferably, a first sealing ring 20 is provided along the bottom side of the oil pressure cavity 18 , and the top of the first sealing ring 20 is in conflict with the bottom side of the ceramic pressure module 1 . This structure can ensure that the oil pressure entering the oil pressure chamber groove 18 is always concentrated on the bottom side of the ceramic pressure module 1, which can effectively prevent the oil from overflowing, a...

Embodiment 3

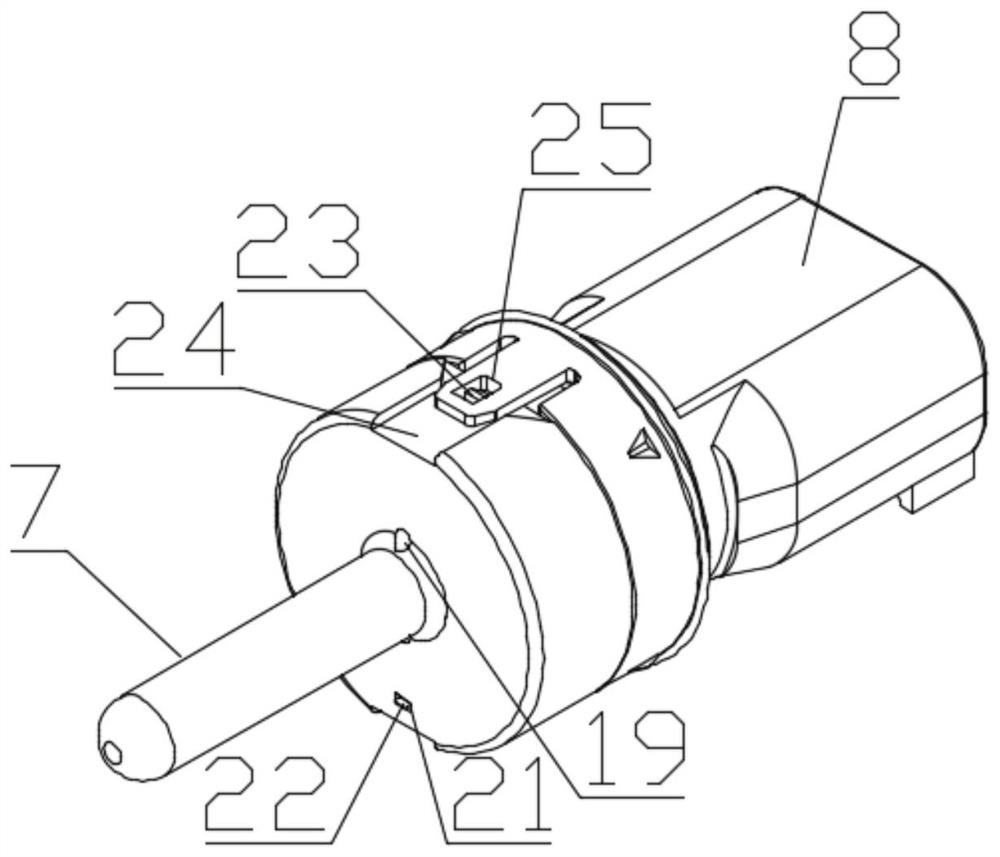

[0049] Such as figure 2 and 6 As shown, the NTC base 7 is also provided with a pogo pin slot 21 for the pogo pin 22 connected to the ceramic pressure module 1 to pass through. After the pogo pin 22 passes through the pogo pin slot 21 Realize the connection with the housing 9 (since the housing 9 is finally connected to the NTC base, the contact of the pogo pin 22 with the pogo pin 22 is equivalent to the final connection with the housing 9).

[0050] Specifically, the pogo pins 22 can realize the electrical connection between the ceramic pressure module 1 and the housing 9, so as to realize good grounding of the internal circuit and the vehicle frame, prevent EMC interference in future work, and avoid various safety accidents caused by EMC. , greatly improving product reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com