Refuse incineration waste gas treatment equipment and use method thereof

A waste gas treatment equipment, waste incineration technology, applied in combustion methods, gas treatment, grain treatment and other directions, can solve problems such as large treatment, difficulty, increased incinerator load, etc., to reduce the content of harmful substances, reduce combustion load, The effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

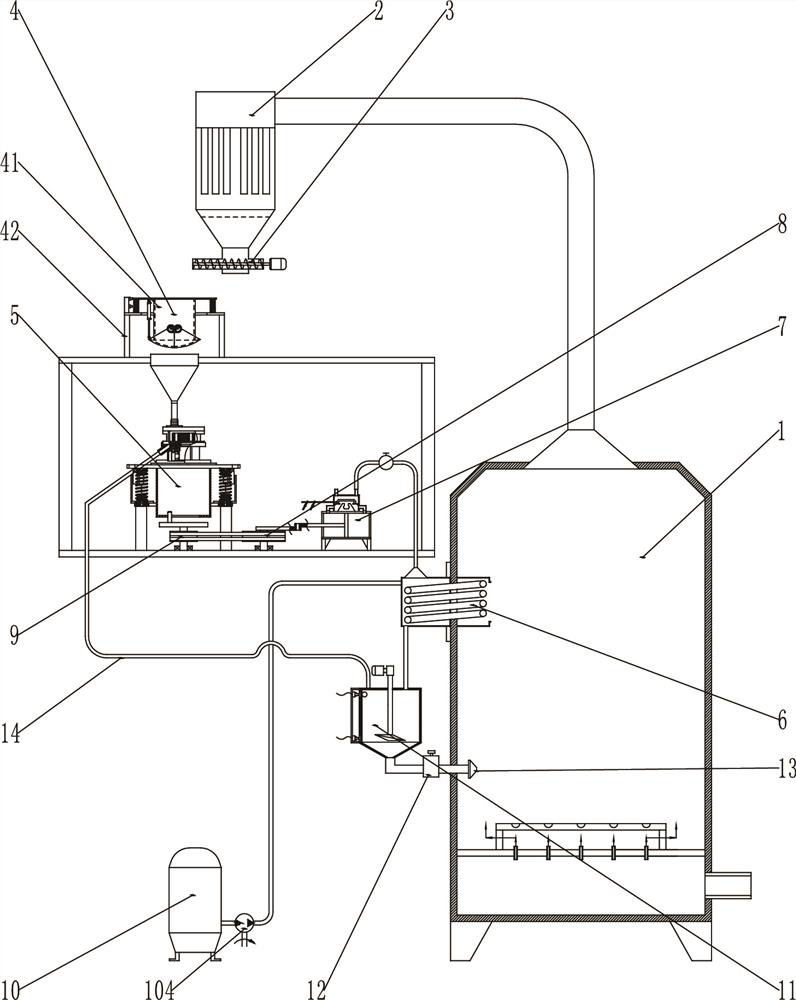

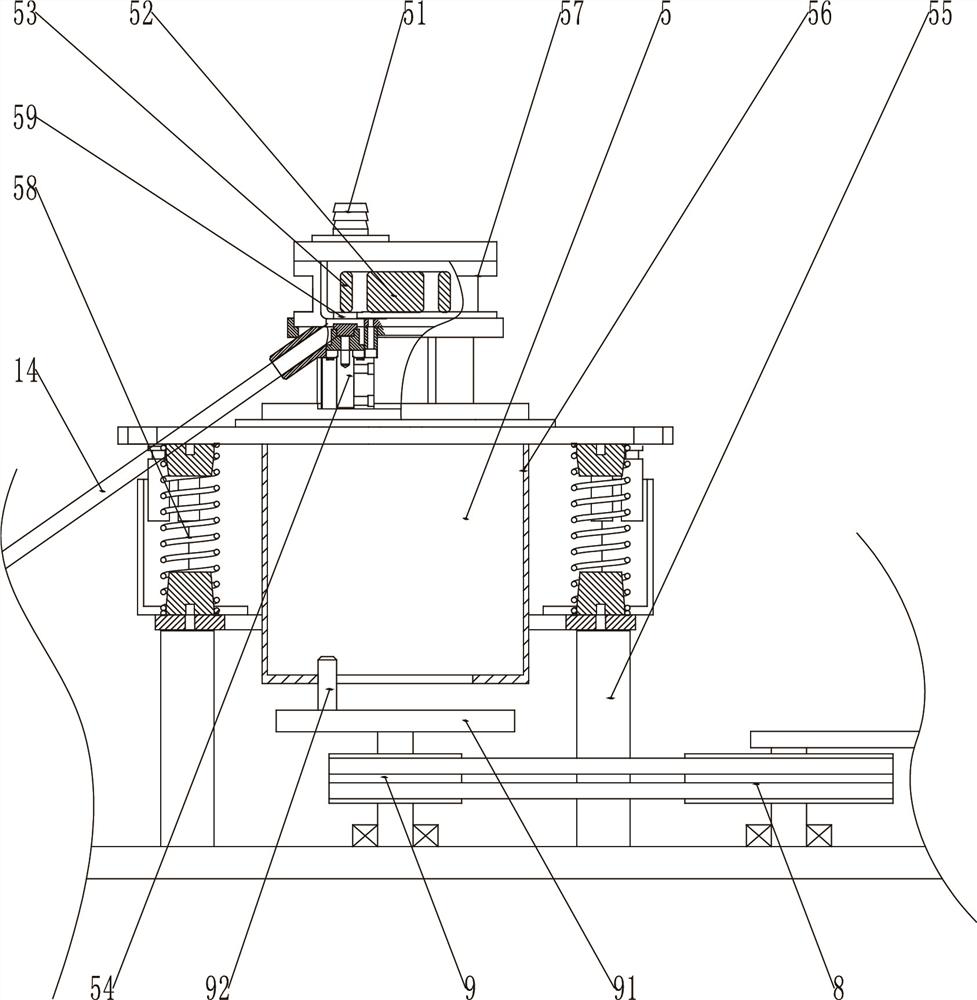

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 4 , a garbage incineration exhaust gas treatment equipment, including an incinerator 1 and a dust collector 2 for collecting large particles of dust, a pipeline is connected between the dust collector 2 and the incinerator 1, and the dust collector 2 is equipped with There are replaceable sieve plates to facilitate the filtration of various sizes of particle dust in the waste gas produced by waste incineration.

[0020] Preferably, the dust collector 2 is provided with a conveyor 3 for conveying particulate dust, the conveying mode of the conveyer 3 is preferably belt conveying or screw conveying, and the conveying motor 3 is provided on the conveyer 3 .

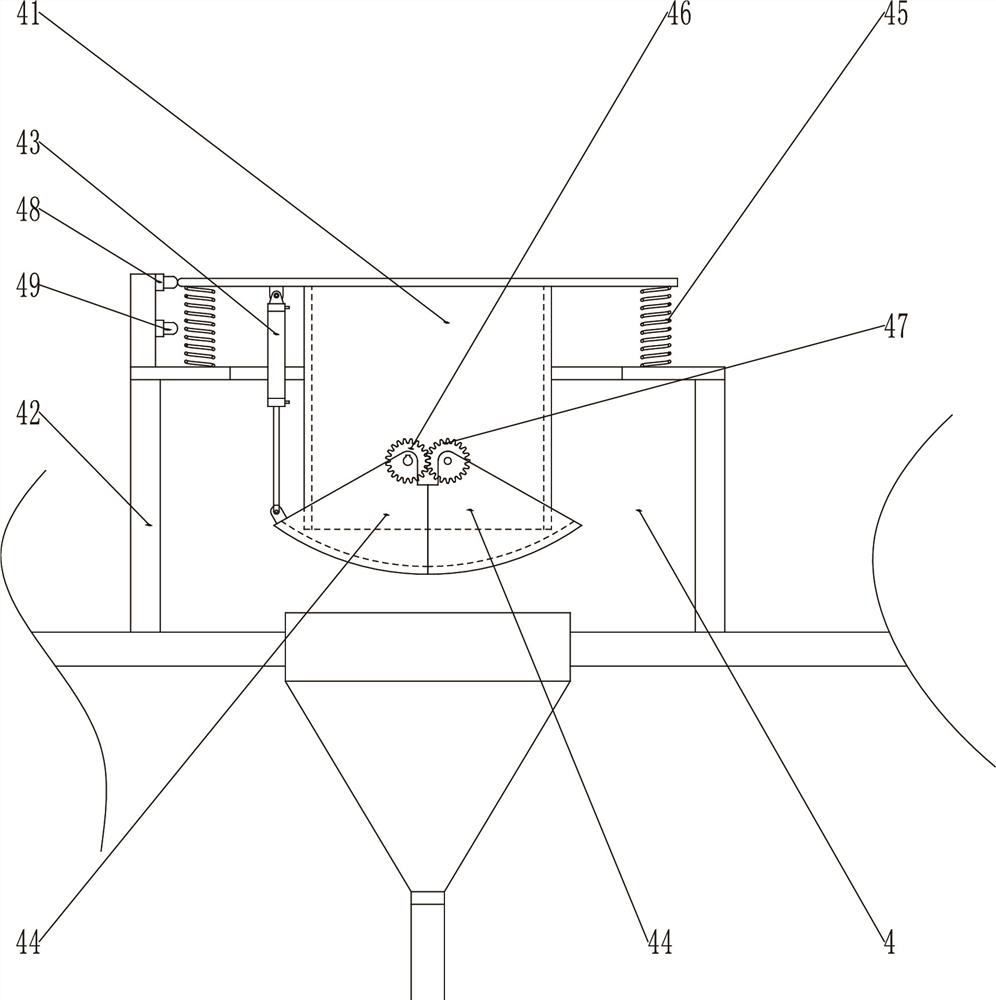

[0021] Preferably, the bottom of the conveyor 3 is provided with a collector 4 that can collect large particles of dust, and the collector 4 includes a collecting hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com