Incinerator for staged combustion of waste refractory materials

A waste refractory material and graded combustion technology, which is applied in the field of incinerators, can solve the problems of refractory materials that are difficult to use or make full use of, adverse effects, and great environmental impacts, and achieve low labor intensity, improved work efficiency, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

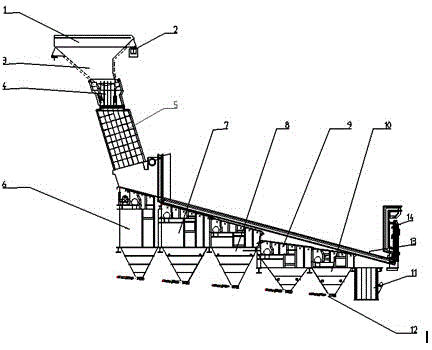

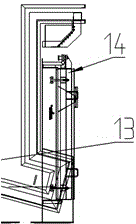

[0013] Such as figure 1 , an incinerator for graded combustion of waste refractory materials, characterized in that it includes a waste material inlet (1), an end cover switch (2), a feeding channel (3), a classifier (4), a filtering channel (5), Drying area (6), primary combustion area (7), secondary combustion area (8), burnout area (9), ash cleaning area (10), non-decomposable storage area (11), pull rod (12), decomposition Gas channel (13), tail gas treatment area (14); the waste material inlet (1) is placed at the uppermost end of the entire incinerator device; the end cover switch (2) is placed on the edge of the waste material inlet (1); The feeding channel (3) is adjacent to the waste material inlet (1) and is distributed in a conical shape; the sieve separator (4) is placed under the feeding channel (3), and inlets of different sizes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com