A garbage incineration device

A garbage incineration and unified technology, applied in the field of machinery, can solve the problems of garbage accumulation, incomplete incineration of garbage, slow incineration efficiency, etc., and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

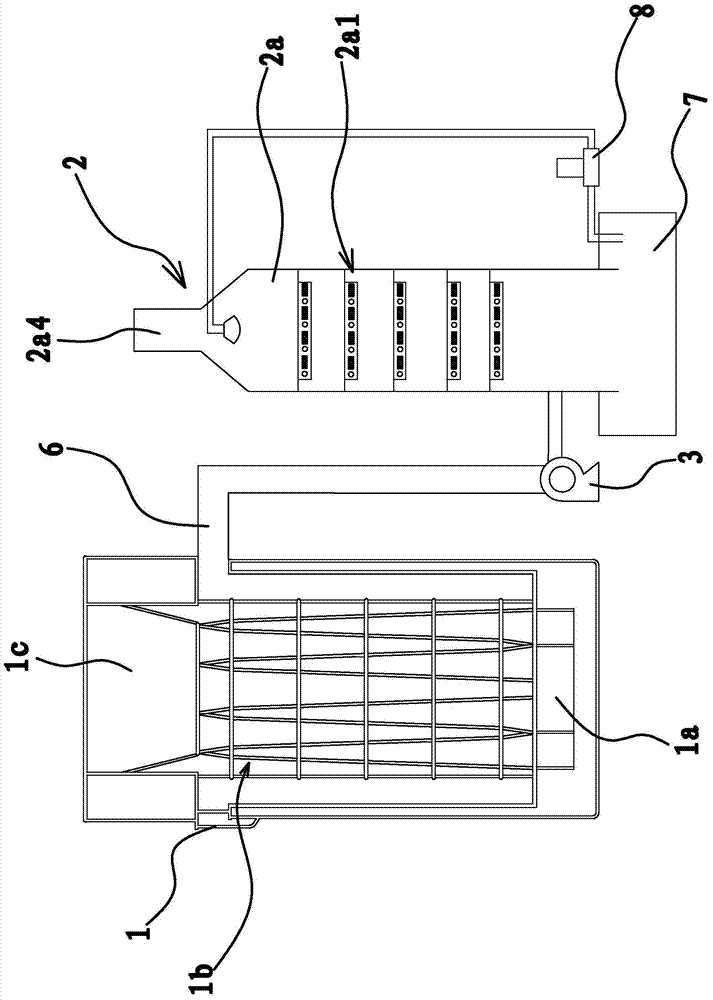

[0034] Such as figure 1 As shown, a garbage incineration device includes a cylindrical tower body 1 with a hollow inner cavity, a smoke processor 2, and an induced draft fan 3 arranged between the tower body 1 and the smoke processor 2. The induced draft fan 3 The air inlet and the air outlet are respectively connected to the tower body 1 and the smoke processor 2. The bottom of the inner cavity of the tower body 1 is provided with a combustion chamber 1a. The garbage disposal port 1c is open and communicated with the inner cavity of the tower body 1 .

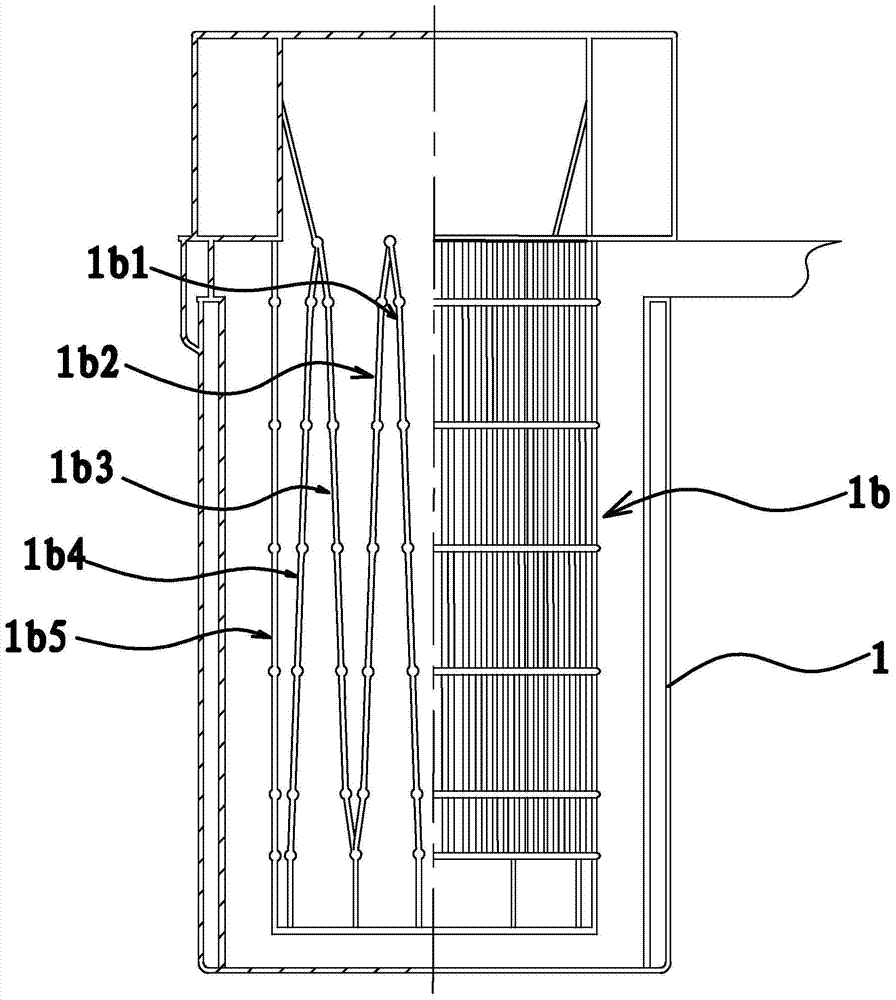

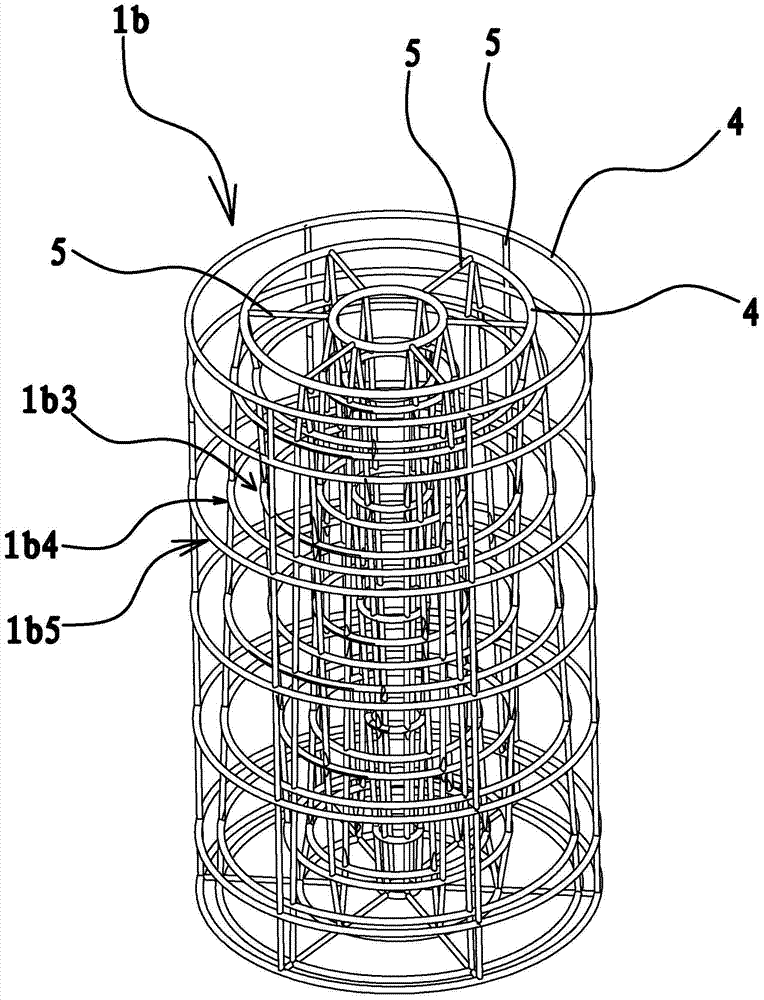

[0035] Such as figure 1 , figure 2 and image 3 As shown, a combustion frame 1b is fixed inside the tower body 1, and the combustion frame 1b is located above the combustion chamber 1a. The combustion frame 1b includes a layer of circular tube group 1b1, a second layer of circular tube group 1b2 and a triple layer of circular tube group 1b3 A layer of circular pipe group 1b1 includes several cold water circular pipes 4 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com