Traction driving pile driver and self-propelled traction driving pile driver

A technology of pile driver and traction, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of easy damage of pile pipe, low production efficiency, complex structure, etc., and achieve energy saving, low production cost, low weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

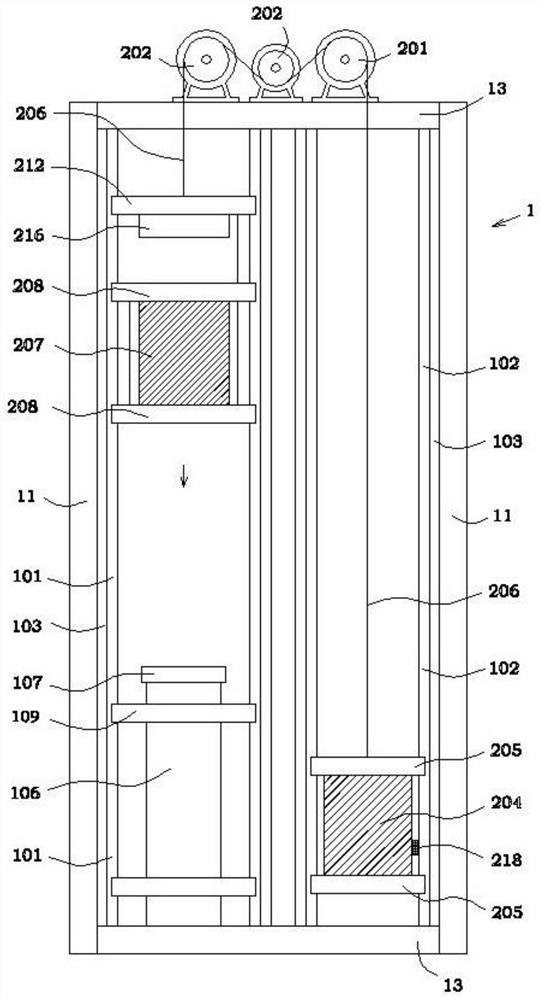

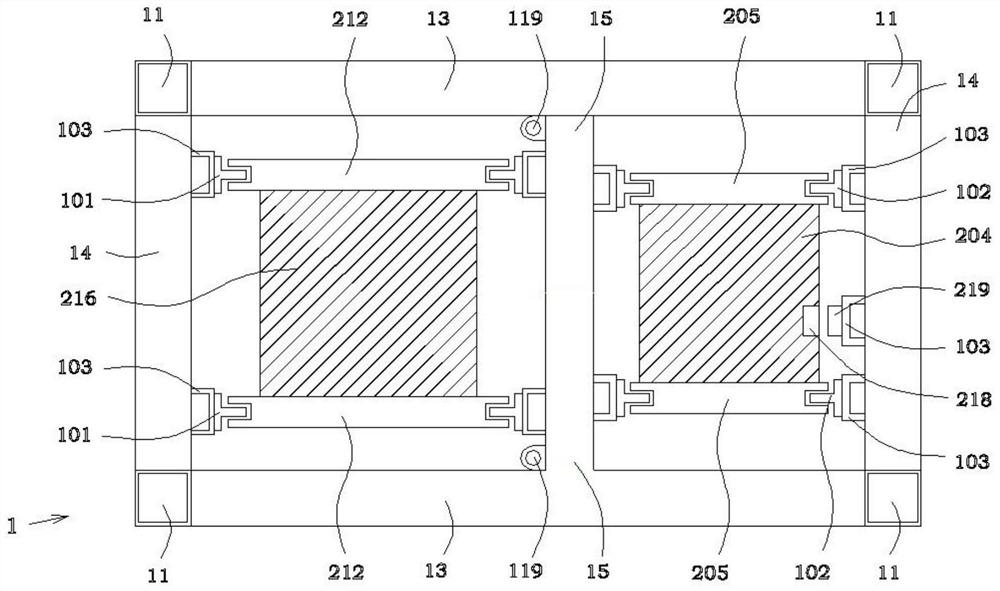

[0042] Example 1: Please refer to figure 1 , The traction-driven pile driver provided by one embodiment of the present invention includes a main pile frame 1, a traction mechanism, a hammer removal device and a hammer body 207. The main pile frame 1 is provided with a longitudinally separated first pile chamber and a second pile chamber. Traction mechanism mechanism comprises traction wheel 201, block pulley 202, traction rope 206 and traction counterweight 204, and traction counterweight 204 is located at the second pile chamber, and is connected with the side sliding of the second pile chamber. The traction wheel 201 is installed on the top of the main pile frame 1 , the traction rope 206 is wound around the traction wheel 201 and the pulley block 202 , and one end of the traction rope 206 is connected to the traction counterweight 204 . Hammer body 207 and hammer-off device are located at the first pile chamber, and are slidably connected with the side of the first pile ch...

Embodiment 2

[0062] Embodiment 2: This embodiment is a self-propelled traction-driven pile driver, which is improved by adding new technical solutions on the basis of Embodiment 1.

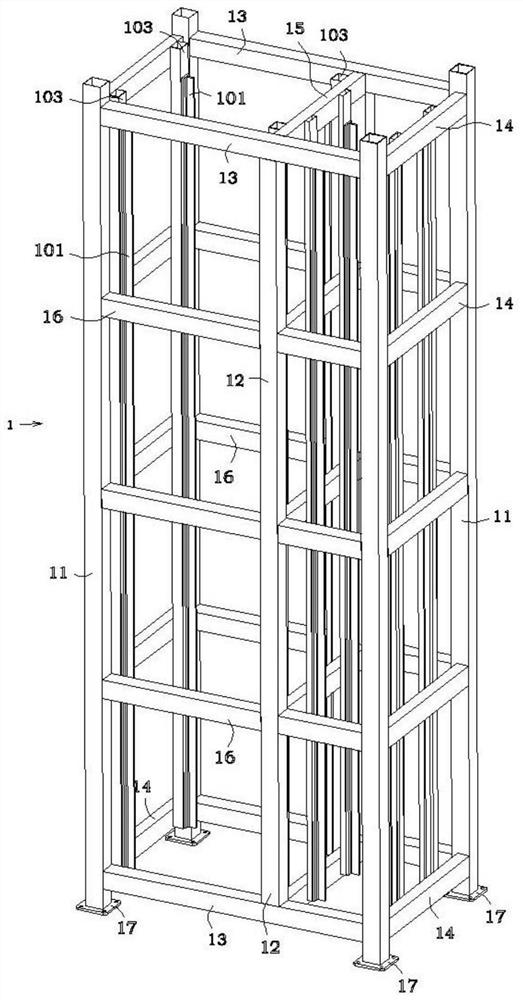

[0063] refer to Figure 7 and Figure 9 As shown, the self-propelled traction-driven pile driver provided by another embodiment of the present invention includes the traction-driven pile driver and the bottom pile frame 2 of any embodiment in the first embodiment, and the bottom pile frame 2 is provided with the first The third pile chamber corresponding to the pile chamber, and the fourth pile chamber corresponding to the second pile chamber, the bottom of the main pile frame 1 and the top of the bottom pile frame 2 are detachably connected. In this way, by installing the main pile frame 1 on the top of the bottom pile frame 2, the height of the main pile frame 1 can be increased so as to be suitable for pile pipes 106 of different lengths. In addition, due to the detachable connection between the main pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com