Continuous feeding device for battery conveying system

A conveying system and battery technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of pallet collapse, troublesome pallet dragging, inability to continuously feed materials, etc., and achieve the effect of avoiding collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

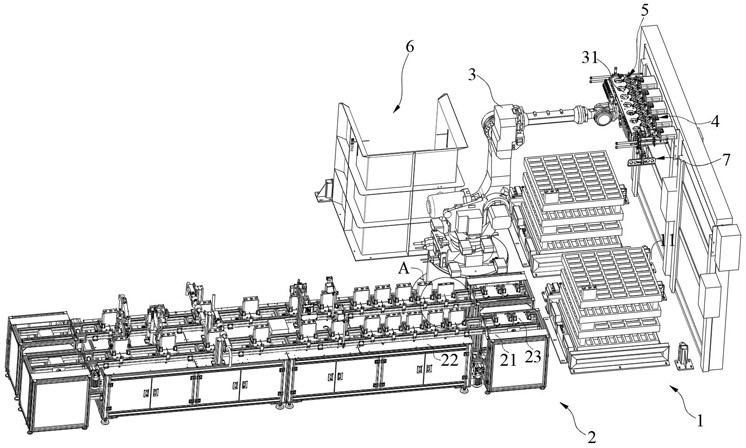

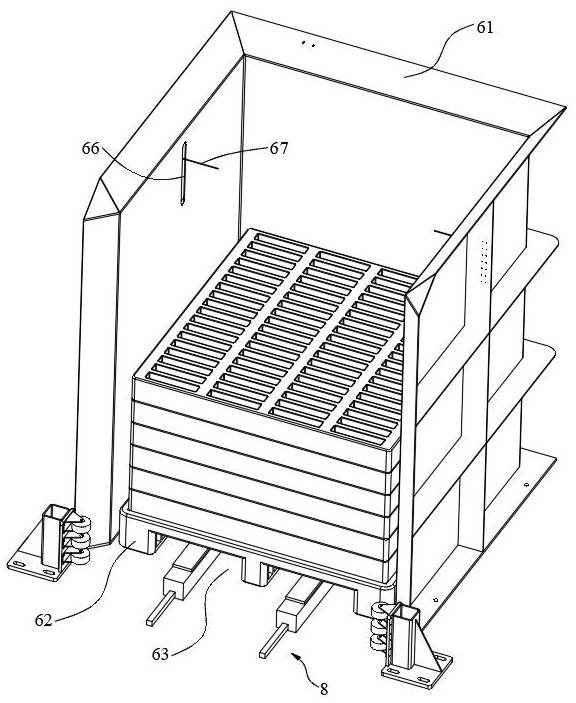

[0043] Such as Figure 1 to Figure 14 As shown, the first embodiment provides a continuous feeding device for a battery delivery system, the specific structure includes:

[0044] Incoming material placement mechanism 1,

[0045] The incoming material placement mechanism 1 is used as the starting point of the entire battery conveying system, and the tray 11 filled with materials will be transported to the position of the incoming material placement mechanism 1, and the tray 11 with materials is positioned by the incoming material placement mechanism 1, The materials on the tray 11 are clamped and transported backwards for processing. Specifically, a plurality of positioning slots 111 are provided in matrix on the tray 11, and the materials are inserted into the positioning slots 111.

[0046] Feeding and conveying mechanism 2,

[0047] The feeding and conveying mechanism 2 is used as a mechanism for conveying materials backward after feeding, and includes a first conveyor 21 ...

Embodiment 2

[0081] On the basis of Embodiment 1, this Embodiment 2 also provides a feeding method for a continuous feeding device for a battery conveying system, including a continuous feeding device for a battery conveying system in Embodiment 1, one of which The continuous feeding device for the battery conveying system is the same as that in Embodiment 1, and will not be repeated here.

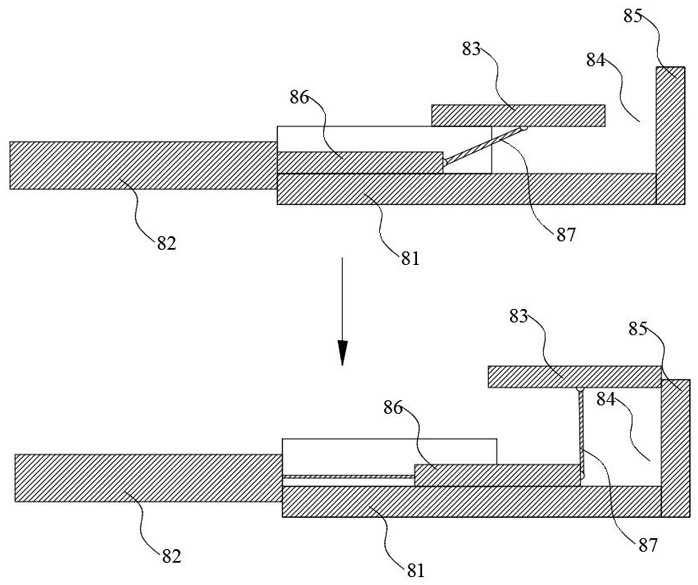

[0082] A specific feeding method of a continuous feeding device for a battery delivery system is as follows: After the tray 11 slides into the placement frame 12, the tray 11 is pushed by the side push cylinder 13 to offset the placement frame 12; the loading is driven by the six-axis manipulator 3 The bracket 31 drives the clamping plate 41 to the corresponding material position; adjusts the direction of the clamping vertical plate 441 and the clamping mounting seat 45 according to the size of the material; drives the two clamping plates 41 to clamp the material through the clamping cylinder 43, and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com