Steel fiber distribution bin, steel fiber metering distribution system and control method

A technology of distributing system and steel fiber, applied in control device, mixing operation control, chemical instrument and method, etc., can solve the problem of unsmooth discharge of storage hopper and inability to control the feeding speed of the first electromagnetic vibrating feeder well And the amount of feed, can not well guarantee the steel fiber drop point and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below through specific embodiments.

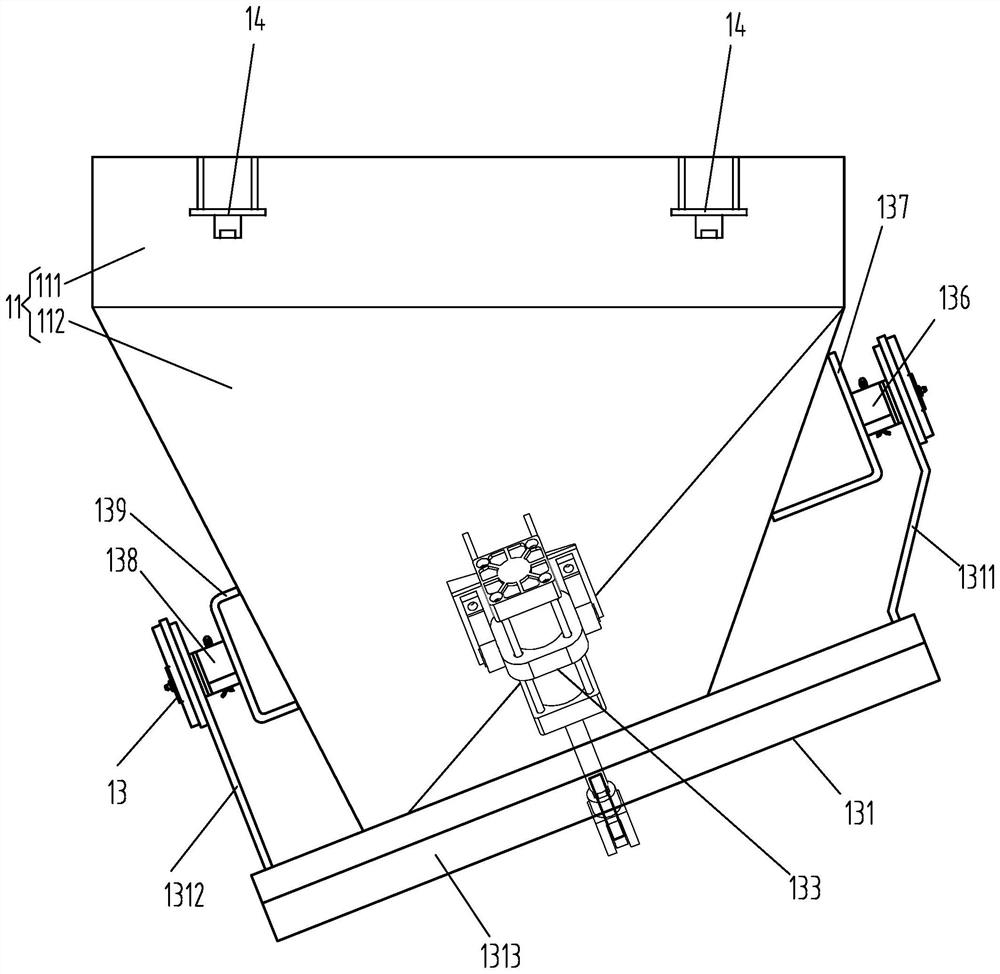

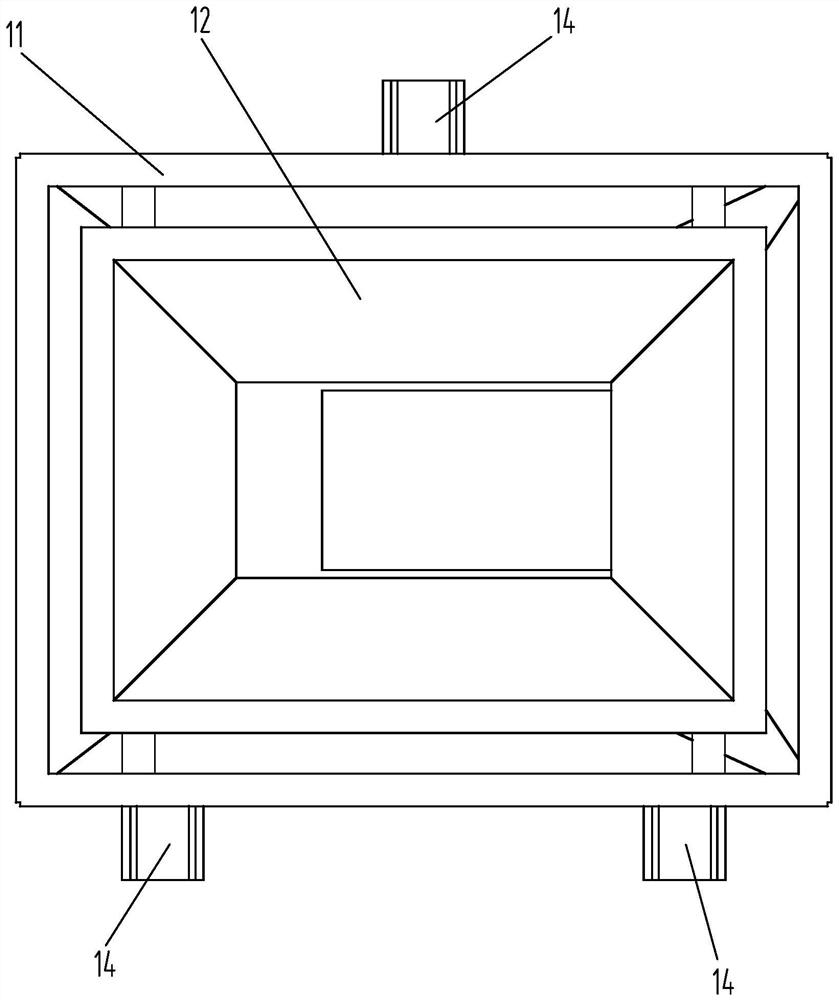

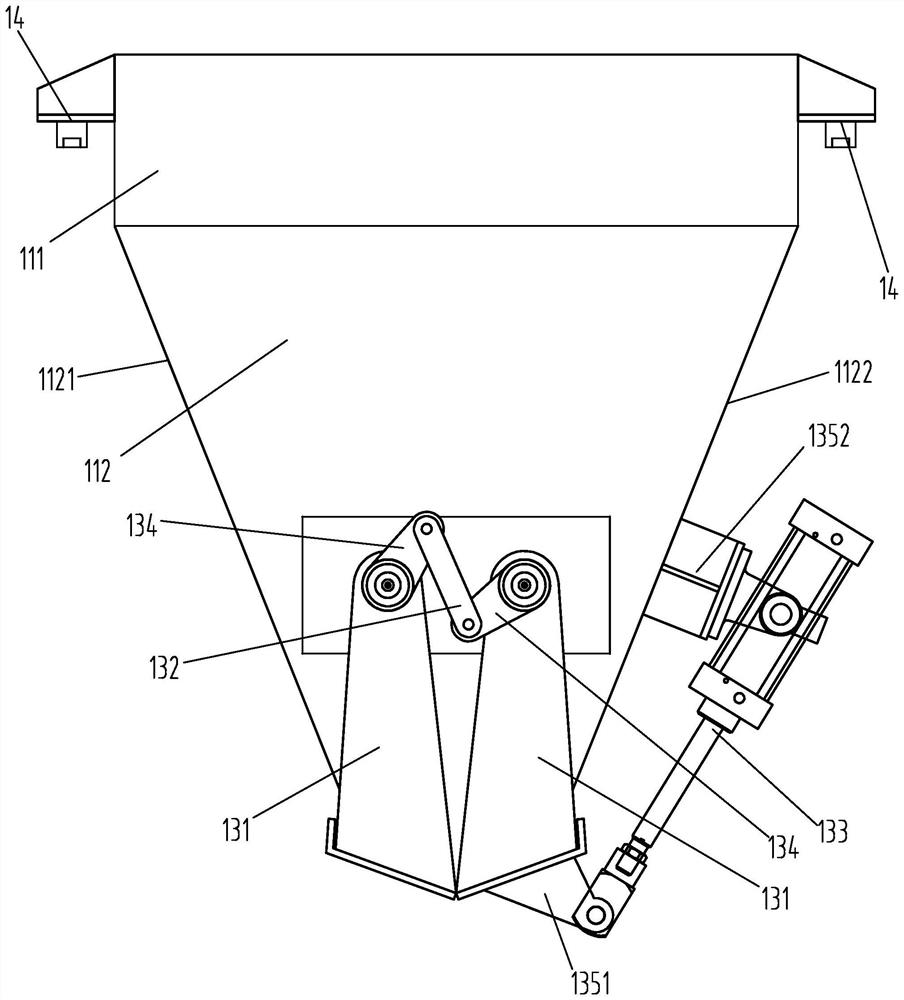

[0037] like Figure 1 to Figure 6 As shown, a steel fiber cloth silo according to the present invention includes a cloth silo body 11, and a plurality of supports 14 for installing the load cell 6 are fixed on the cloth silo body 11. 11 is provided with a distribution cavity open at the upper and lower ends, and a discharge port 1125 is formed at the lower end thereof. An inner bucket body 12 is fixedly connected in the distribution cavity, and the upper end of the inner bucket body 12 is connected with the distribution bin body 11. The upper ends are flush with each other, the lower end of the inner bucket body 12 extends to the bottom of the distribution cavity, the inner bucket body 12 is provided with a feeding cavity opened at the upper and lower ends, and a feeding port is formed at the upper end thereof, and the steel fibers pass through. The feeding cavity enters the center of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com