Whole-course recycling sea sand chlorine removal and impurity removal system

A technology of resource utilization and sea sand, applied in the field of building materials, can solve the problems of polluted soil, water source food chain, increased cost of sea sand treatment, secondary pollution of the ecological environment, etc., to achieve improved chlorine removal efficiency, high production efficiency, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

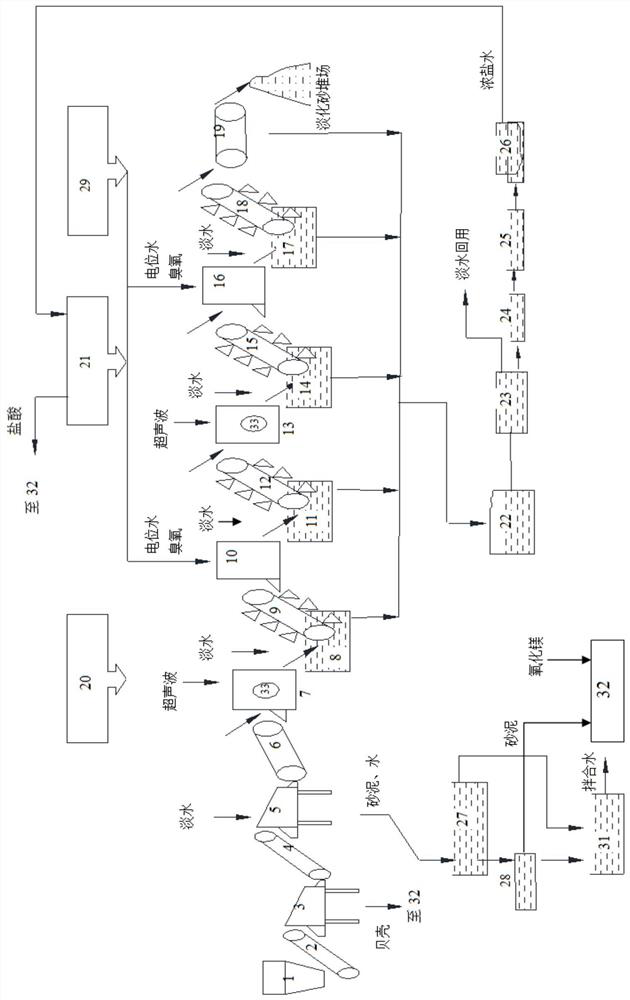

[0040] Such as figure 1 The shown one embodiment of the present invention's full resource sea sand removal and chlorine removal system includes: screening unit, cleaning and showering unit, impurity separation unit, ultrasonic generator, alkaline potential water generator, low pressure ozone generator Array stack, linear vibrating conveying screen water unit 19, flocculation tank 27, filter press 28, water collection tank 22, reverse osmosis treatment tank 23, two sun steamers 24, 25 and concentrated brine collection unit 26. details as follows:

[0041]The screening unit is used to remove impurities and silt in the sea sand, and send the removed sea sand to the cleaning and showering unit. The screening unit includes a first vibrating screen 3, a second belt conveyor 4, a second vibrating screen 5 and a third belt conveyor 6, and the first vibrating screen 3 is used to screen out shells and pebbles in sea sand raw materials The second belt conveyor 4 is used to send the sea...

Embodiment 2

[0078] The whole process resource sea sand removal and chlorine removal system differs from the first embodiment in that only one cleaning and showering unit is provided, that is, the first cleaning and showering unit. Sea sand is sent to the linear vibrating conveying sieve water unit 19 through the second bucket elevator 12 after being cleaned and rinsed by the cleaning and showering sheet, and the sand and water are separated. The separated clean sea sand is sent to the desalinated sand yard for storage. All indicators of the sea sand processed by the system meet the national and international standards.

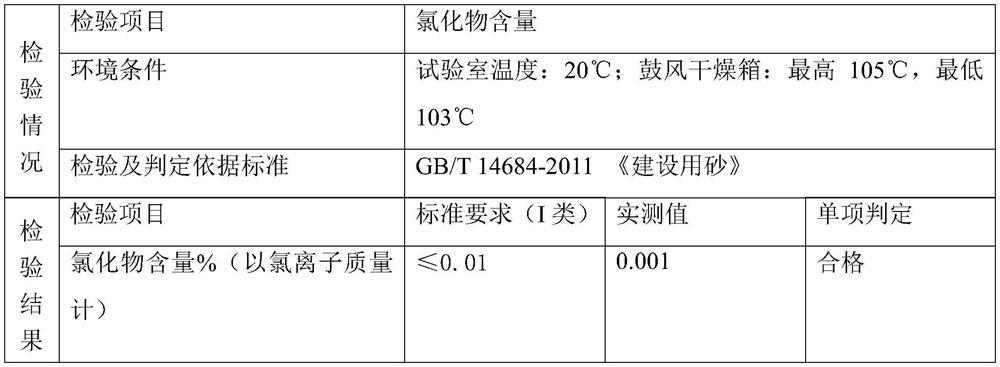

[0079] The chloride content and other impurity content of sea sand treated by the above system can also meet the requirements of national and international standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com