A new type of injection molding machine for sports equipment production

A technology of sports equipment and plastic spraying machine, which is applied to the device and coating of the surface coating liquid, so as to avoid moisture, avoid dust, and ensure the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

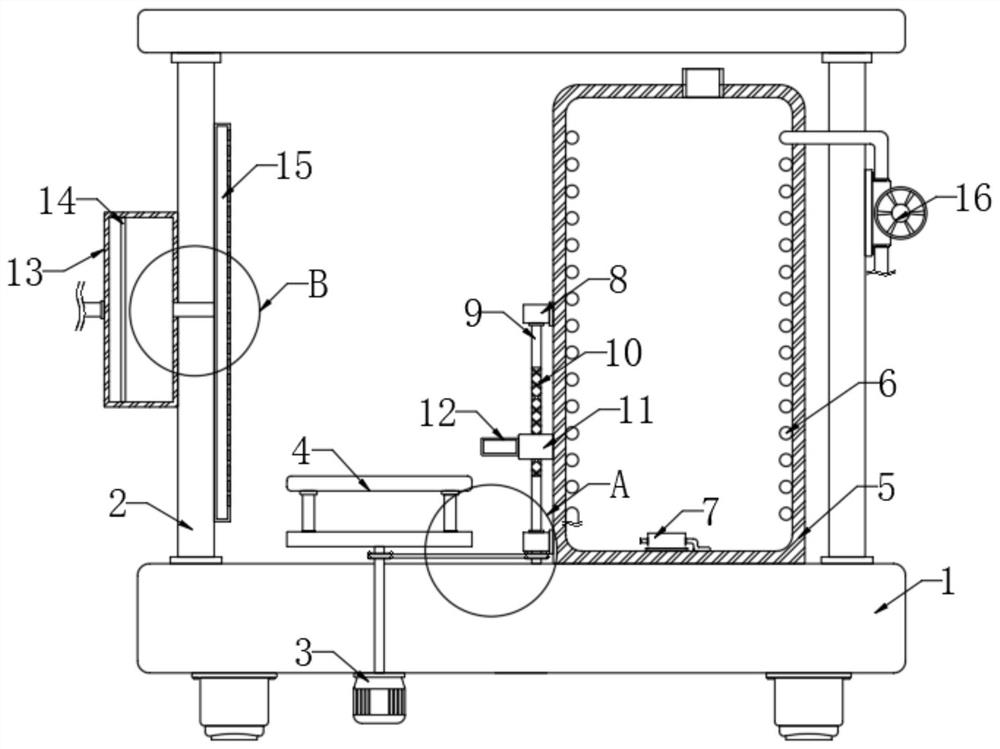

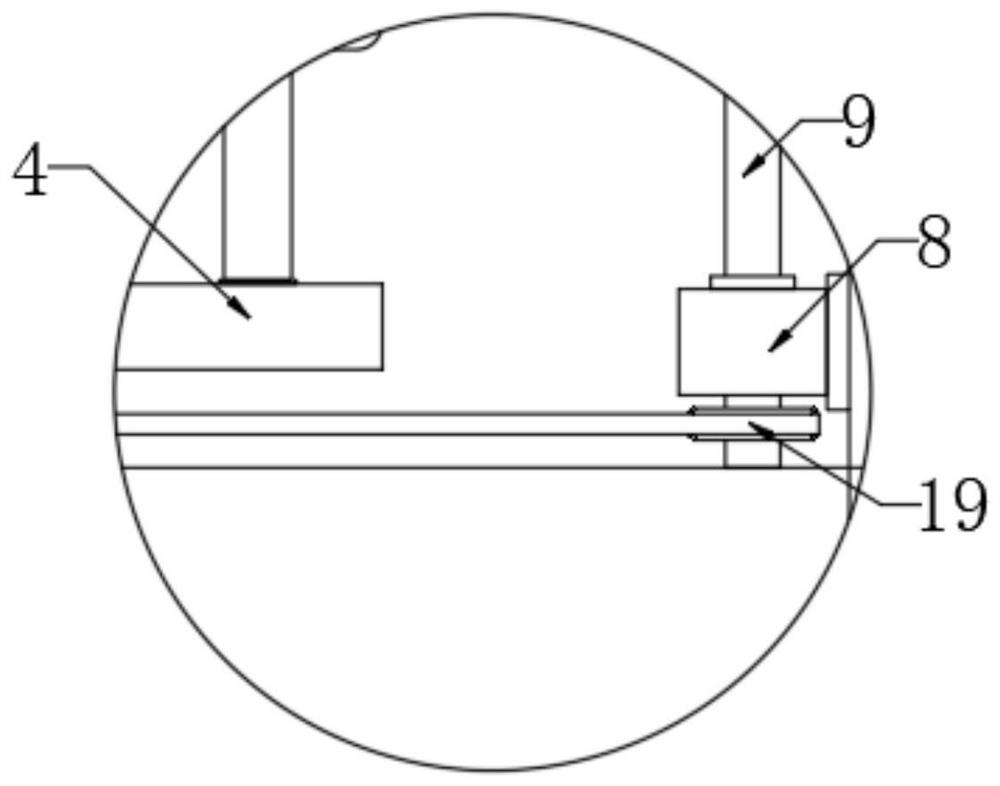

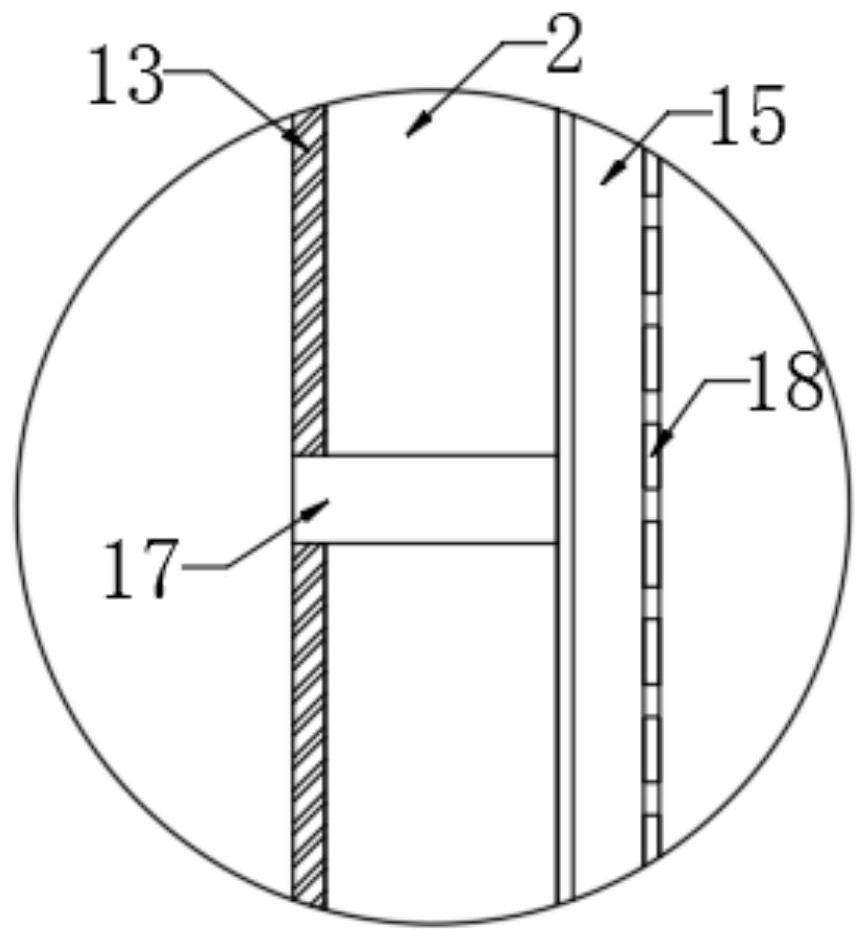

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

[0021] refer to Figure 1-3 , a new type of plastic spraying machine for sports equipment production, comprising a bottom plate 1, the upper end of the bottom plate 1 is symmetrically and fixedly connected with two mounting plates 2, the upper ends of the two mounting plates 2 are fixedly connected with a top plate, and the upper end of the bottom plate 1 is fixedly connected with a In the storage box 5, a plurality of support blocks are installed on the lower end of the bottom plate 1, and anti-skid pads are installed on the lower ends of the plurality of support blocks to ensure the stability of the machine during operation;

[0022] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com