A kind of cerium oxide coated micron copper powder and its preparation method and application

A technology of the first cerium oxide and cerium oxide, which is applied in the direction of carbon monoxide, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult modification of micron copper powder, and achieve high catalytic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

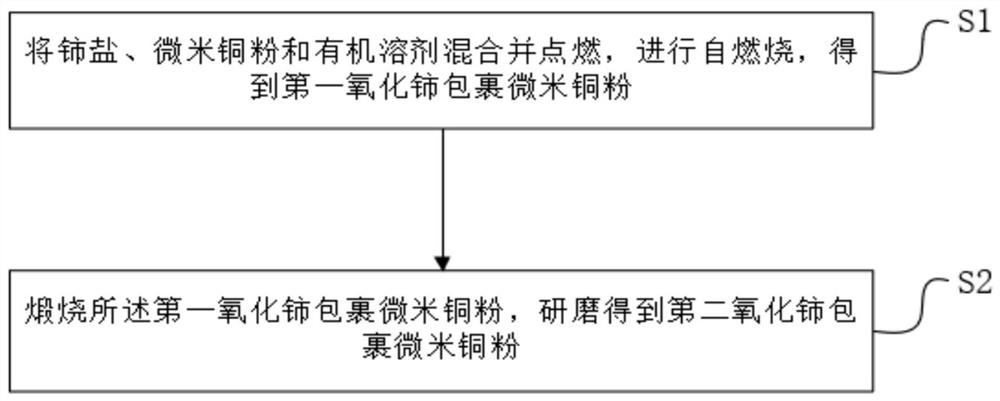

[0026] figure 1 As shown, in one embodiment of the present application, the present application provides a preparation method of cerium oxide-coated micron copper powder, the method comprising:

[0027] S1. cerium salt, micron copper powder and organic solvent are mixed and ignited, and self-combustion is carried out to obtain the first cerium oxide-wrapped micron copper powder;

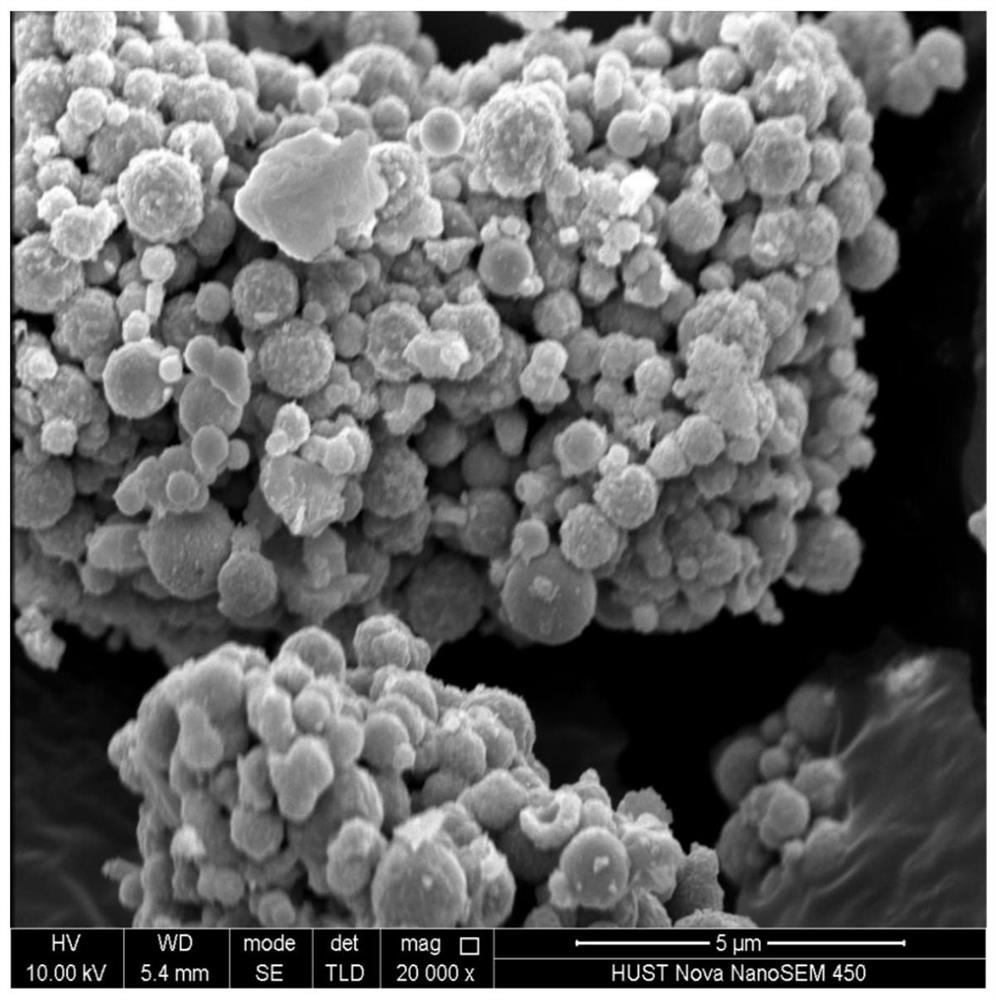

[0028] The first cerium oxide-wrapped micron copper powder has a core-shell structure, wherein the mass ratio of the outer cerium oxide and the inner core copper micro-particles is 1.5-2:1.

[0029] In general, the first cerium oxide-coated micron copper powder is a gray solid.

[0030] In this application, the purpose of limiting the mass ratio of cerium oxide and micron copper powder to 1.5-2:1 is to make cerium oxide wrap micron copper powder to form a core-shell structure and a Cu-Ce interface; when the mass ratio is too large, The resulting adverse effect is that cerium oxide completely wraps ...

Embodiment 1

[0049] Select cerium salt as cerium acetate;

[0050] The mass-volume ratio of cerium acetate, micron copper powder and ethanol is 2.78g:1g:5ml;

[0051] The cerium acetate, the micron copper powder and the ethanol are mixed and stirred for 30 minutes until uniform, ignited, and self-combustion is carried out to obtain the first cerium oxide-coated micron copper powder;

[0052] The obtained first cerium oxide-wrapped micron powder has a core-shell structure, wherein the mass ratio of the outer cerium oxide and the inner core copper micro-particles is 1.5:1;

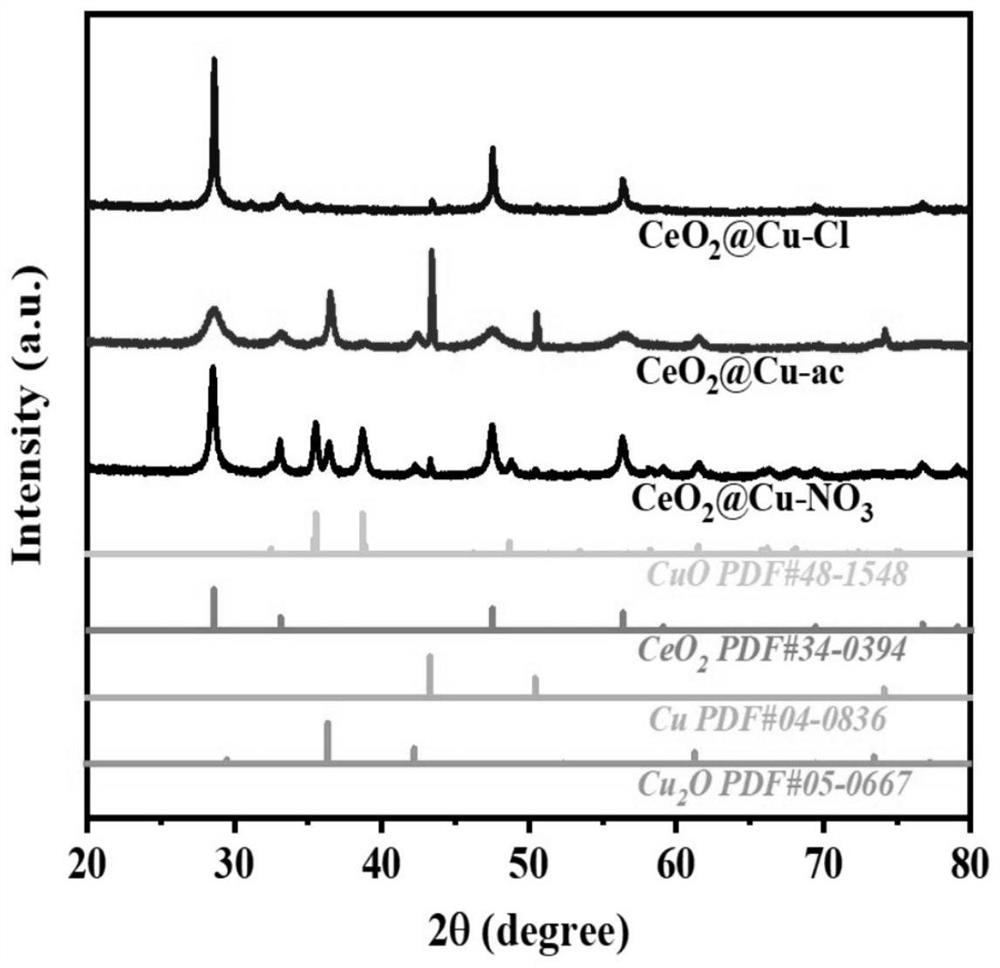

[0053] In an air atmosphere, the first cerium oxide-coated micron copper powder was calcined at a calcination temperature of 500 °C for 1 h, and ground to obtain a second cerium oxide-coated micron copper powder, which was denoted as CeO 2 @Cu-ac.

Embodiment 2

[0055] Select cerium salt as cerium acetate;

[0056] The mass volume ratio of cerium acetate, micron copper powder and ethanol is 0.92g: 1g: 5ml;

[0057] The cerium acetate, the micron copper powder and the ethanol are mixed and stirred for 30 minutes until uniform, ignited, and self-combustion is carried out to obtain the first cerium oxide-coated micron copper powder;

[0058] The obtained first cerium oxide-wrapped micron copper powder has a core-shell structure, wherein the mass ratio of the outer cerium oxide and the inner core copper microparticles is 0.5:1;

[0059] In an air atmosphere, the first cerium oxide-coated micron copper powder was calcined at a calcination temperature of 500° C. for 1 h, and ground to obtain a second cerium oxide-coated micron copper powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com