Rock burst roadway hydraulic support type selection method

A technology of hydraulic support and ground pressure impact, which is applied in the field of mining, can solve the problems of unreasonable selection of roadway support hydraulic support and impact ground pressure roadway, etc., and achieve the effect of increasing the safety factor of the roadway, avoiding casualties, and protecting against failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

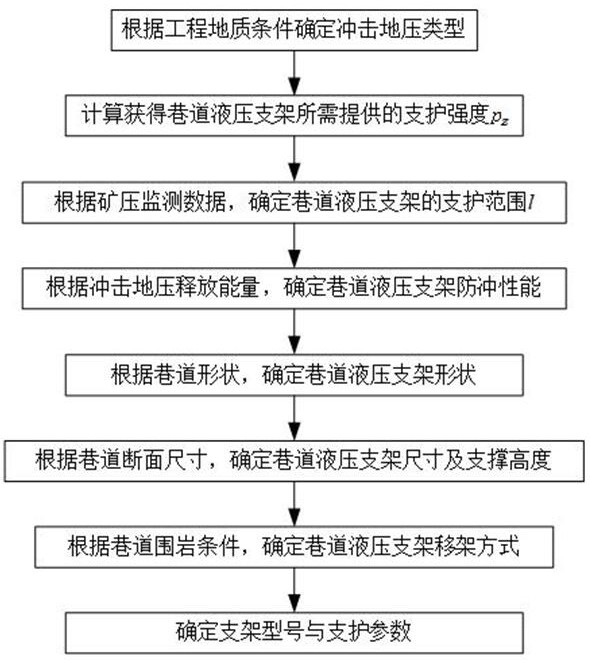

Method used

Image

Examples

specific Embodiment

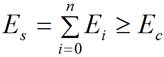

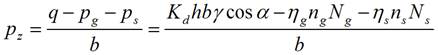

[0059] In this embodiment, a concrete implementation method of a type selection method for rock burst roadway support hydraulic support provided by the present invention is further described in conjunction with a certain mine engineering example. The 11302 working face of a certain mine mined the 3-1 coal seam, the average thickness of the coal seam is 4.0m, the coal seam layer is stable, and the thickness change is small. The upper 7m of the coal seam is mudstone with a uniaxial compressive strength of 22MPa; the upper 7-24m of the coal seam is sandy mudstone with a uniaxial compressive strength of 25MPa; the upper 24-35m of the coal seam is medium sandstone with a uniaxial compressive strength of 34MPa; The lower part is 10m thick sandy mudstone with a uniaxial compressive strength of 22MPa. The 11302 air return roadway is excavated along the bottom, with solid coal on both sides. The shape of the roadway section is rectangular, and the roadway size width×height=5.5m×3.6m. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com