Hydraulic motor fault detection method, device and system and excavator

A hydraulic motor and fault detection technology, which is applied in fluid pressure actuation device, fluid pressure actuation system test, soil mover/shovel, etc., can solve problems such as manual fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

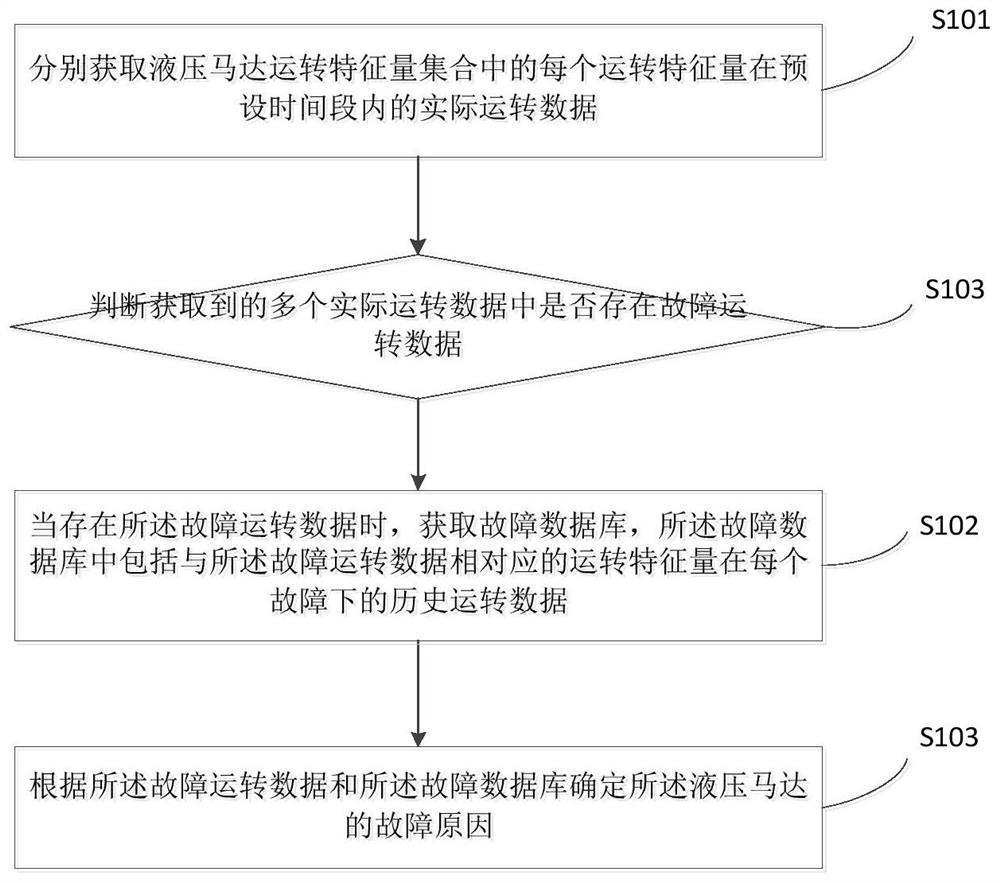

[0022] Embodiment 1 of the present invention provides a hydraulic motor fault detection method. figure 1 It is a schematic flowchart of the hydraulic motor fault detection method in Embodiment 1 of the present invention, such as figure 1 As shown, the hydraulic motor fault detection method in Embodiment 1 of the present invention includes the following steps:

[0023] S101: Respectively acquire actual operation data of each operation characteristic quantity in the hydraulic motor operation characteristic quantity set within a preset time period.

[0024] In Embodiment 1 of the present invention, the operation characteristic quantities in the operation characteristic quantity set include one or more of the following: pressure, rotational speed, and flow rate. Correspondingly, the actual operation data includes one or more of the following: pressure operation data, rotational speed operation data, and flow rate operation data.

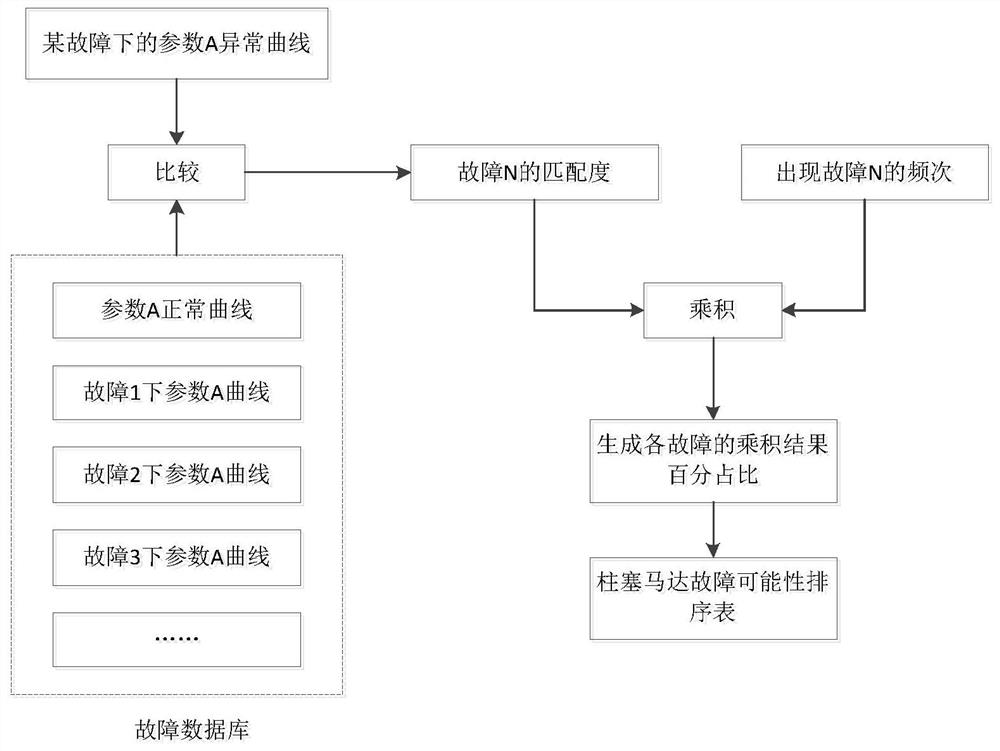

[0025] As a specific embodiment, the hydraulic m...

Embodiment 2

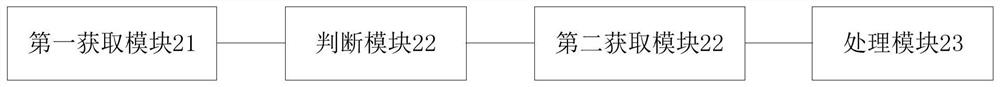

[0048] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a hydraulic motor fault detection device, image 3 It is a schematic structural diagram of the hydraulic motor fault detection device in Embodiment 2 of the present invention, as shown in image 3 As shown, the hydraulic motor fault detection device according to the second embodiment of the present invention includes a first acquisition module 21 , a judgment module 22 , a second acquisition module 23 and a processing module 24 .

[0049] Specifically, the first acquisition module 21 is configured to separately acquire the actual operation data of each operation characteristic quantity in the hydraulic motor operation characteristic quantity set within a preset time period;

[0050] The judgment module 22 is used for judging whether there is faulty operation data in the obtained multiple actual operation data;

[0051] The second acquisition module 23 is configured to...

Embodiment 3

[0055] An embodiment of the present invention further provides a hydraulic motor failure detection system, the hydraulic motor failure detection system includes an operation data detection device and a controller, the operation data detection device and the controller are connected in communication with each other, and the controller Computer instructions are stored in the controller, and the controller executes the fault detection method described in Embodiment 1 of the present invention by executing the computer instructions.

[0056] Specifically, the hydraulic motor is a plunger motor, and the operation data detection device includes a pressure sensor, a rotational speed sensor and a flow sensor; the pressure sensor is used to detect the pressure of the A port, the B port pressure and the T port pressure of the hydraulic motor; The rotational speed sensor is used for detecting the rotational speed of the main shaft of the hydraulic motor; the flow sensor is used for detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com