Construction process of modified asphalt pavement surface layer

A technology of modified asphalt and construction technology, applied in the direction of coagulation pavement, roads, roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

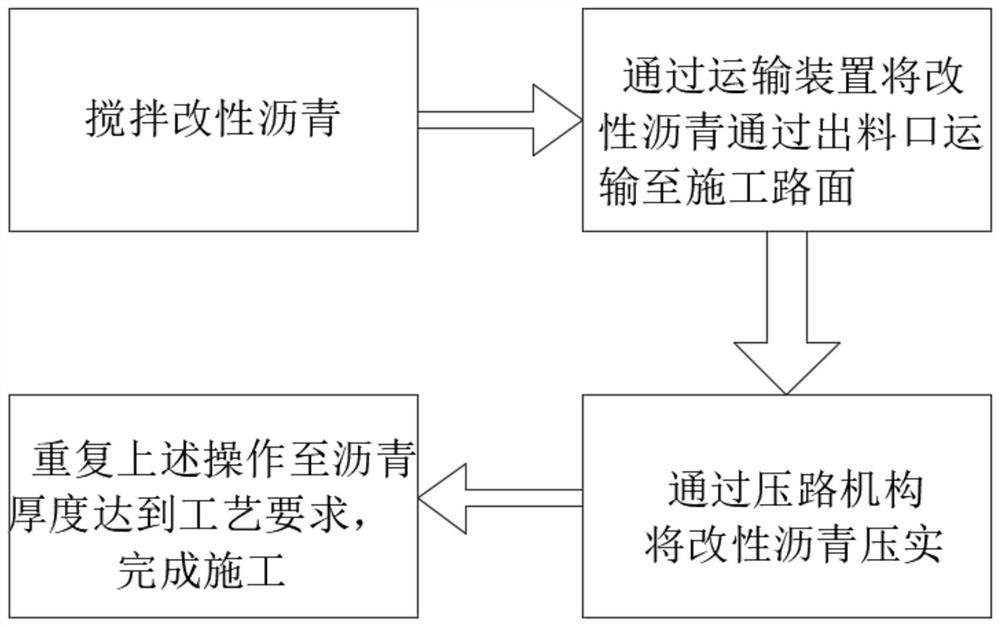

[0079] See figure 1 , figure 2 The present invention provides a technical solution:

[0080] A modified asphalt pavement surface layer construction process, including construction of the road surface layer through the paver, the construction of the paveled pavement surface layer includes the following steps:

[0081] S1, the mixing device of the modified bitumen is placed in the paver is stirred;

[0082] S2, the agitation modified asphalt transports the transport device 6 of the paver to the second discharge port 10 of the paver and placed in the construction road surface layer;

[0083] S3, using the paver circuit mechanism 9 to compact the modified asphalt;

[0084] S4, repeat the above operation until the thickness of the modified asphalt layer reaches the process requires preset thickness, and completes the construction of the road surface layer;

[0085] Preferably, the modified asphalt material comprises: direct distillation asphalt, oxidation asphalt, modifier

[0086] Pre...

Embodiment 2

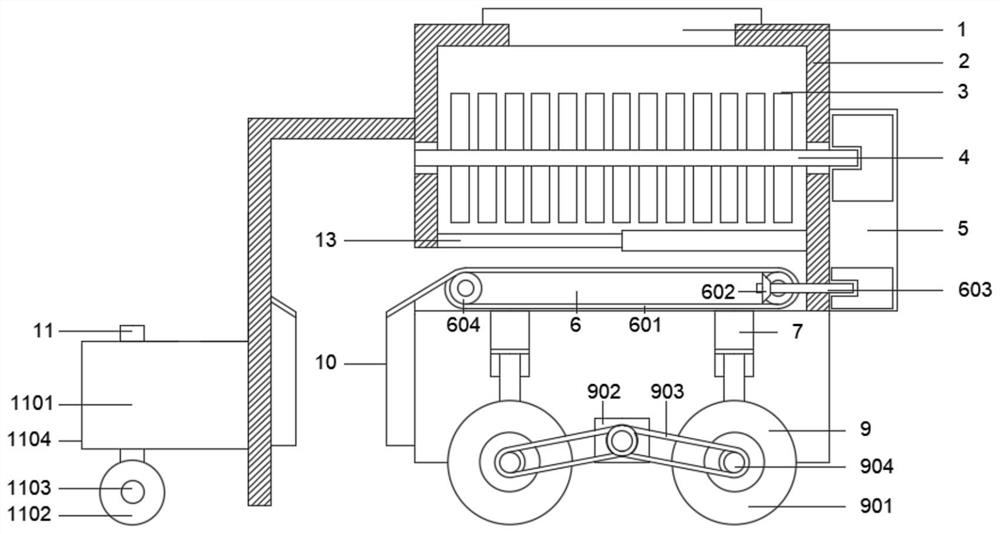

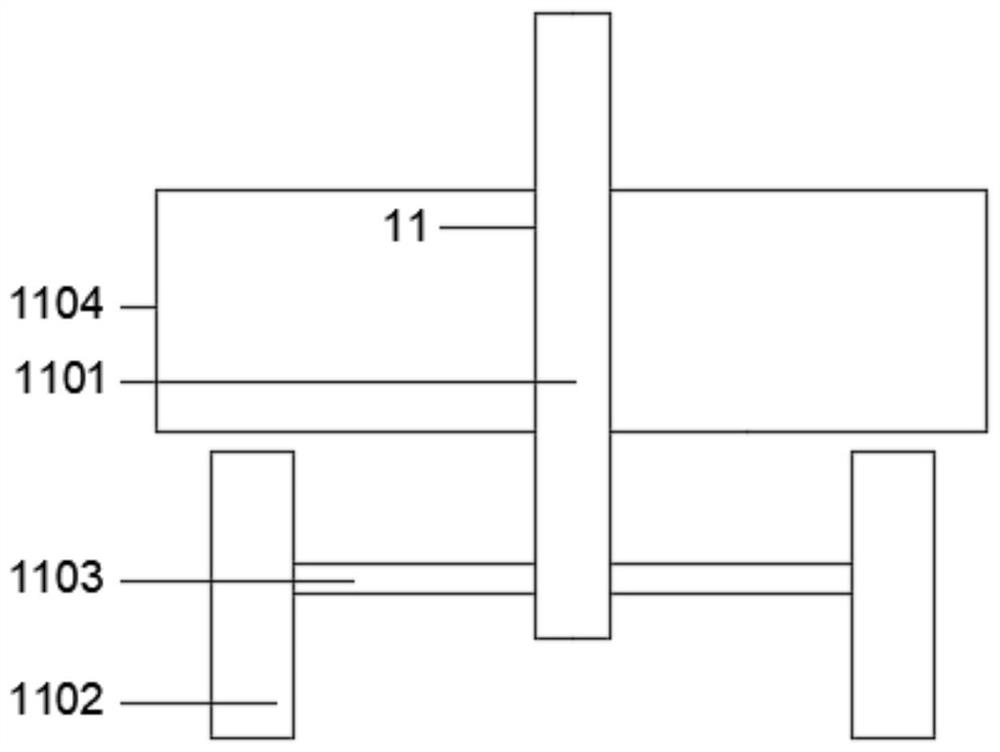

[0093] See figure 2 Based on the first embodiment, the present invention provides a technical solution:

[0094] The transport device 6 includes:

[0095] The track 601, the main motion cone gear 602, the rotation shaft 603, the crawler 604;

[0096] The rotating shaft 4 is configured with two track wheels 604, and a track 601 is provided on two of the tracks 604;

[0097] The main drive cone gear 602 is engaged in the rotating shaft 603, and the main drive cone gear 602 is fixedly mounted on the rotation shaft 603, and the rotating shaft 603 is fixedly coupled to the motor 5.

[0098] The advantageous effect of the above technical solution is: when the transport device 6 operates, the motor 5 rotates the rotation shaft 603 and the main drive beater gear 602, the main drive cone 602 drives the track wheel 604 to rotate and drive the track 601 to rotate, will track the track 601 The upper modified asphalt is transported to improve the functionality of the device and improve its aut...

Embodiment 3

[0100] See figure 2 Based on Examples 1, 2, the present invention provides a technical solution:

[0101] The hydraulic rod 7 is provided in the lower end device housing 2, and the pressure path mechanism 9 includes:

[0102] Pressure wheel 901, voltage path motor 902, transmission belt 903, transmission shaft 904

[0103] The lower end of the hydraulic rod 7 is rotated to provide a transmission shaft 904 to penetrate the transmission shaft 904 or the transmission shaft 904 on one side, the transmission shaft 904 peripheral side, a press wheel 901;

[0104]The hydraulic rod 7 is fixedly mounted between the lower end device housing 2, which is connected between the transmission shaft 903 and the drive shaft 904.

[0105] The advantageous effect of the above technical solution is: when the pressure path mechanism 9 is used, the hydraulic rod 7 is fixed to the vertical position of the pressing wheel 901, and after the circuit motor 902 operates, the transmission belt 903 is rotated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com