Method and device for realizing weft-direction vertical yarn of three-dimensional multilayer profiling woven fabric

A three-dimensional multi-layer, profiling machine technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of non-3D fabrics, low cost, and difficulties in three-dimensional weaving, so as to increase fiber volume content, reduce costs, Designable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

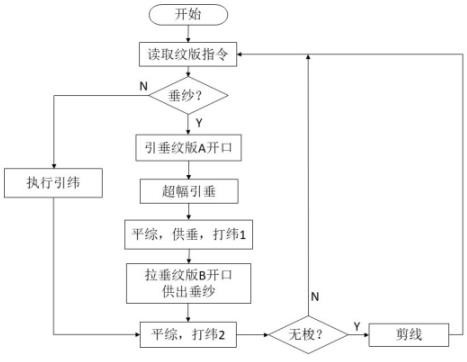

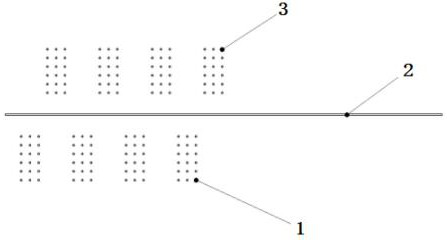

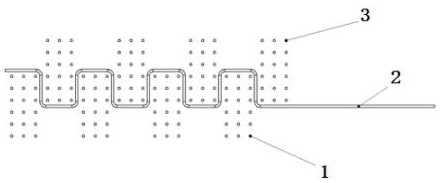

[0042] A device for realizing weft draping of three-dimensional multilayer profiling woven fabrics, including an electronic jacquard opening device, a weft draping device with a yarn supply device, a two-position beating-up device, and a multi-layer weft insertion with a yarn supply device device, a warp let-off device and a pulling device that cooperate with the multi-layer weft insertion device, wherein,

[0043] The shedding device of the electronic jacquard machine can realize the drooping shed and the drooping shed required by the weft vertical yarn;

[0044] The weft drooping device includes a yarn supply device, which can realize drooping of weft yarns and satisfy the excessive drooping of the yarn length L of weft drooping yarns; at the same time, empty weft insertion can be realized, that is, in the When the opening device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com